Smart Machinery Made in Taiwan

“Smart manufacturing is a perfect example of Taiwan’s culture of continuous improvement at work. Small-scale manufacturing, testing and R&D tend to happen in Taiwan while, once processes are honed, the Taiwanese are very pragmatic about moving large-scale manufacturing across to China or other locations around the world.”

A close, yet complex, relationship with Beijing has also allowed Taiwan to find ongoing high-tech manufacturing success where some other Asian powerhouses have stumbled. Taiwan is indeed taking advantage of mainland China’s strengths when it comes to the economies of scale that come with a large landmass and population. Some of Taiwan’s manufacturing is also offshored to neighbors in Southeast Asia such as Thailand and Vietnam.

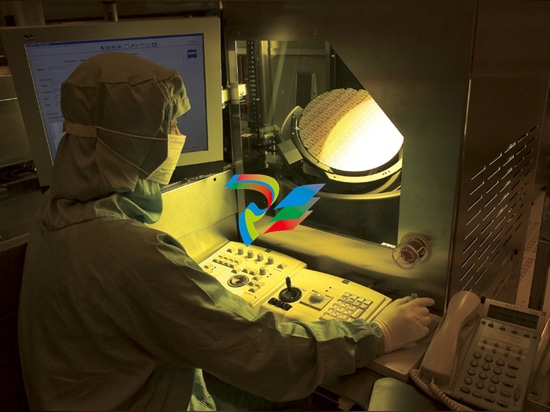

Taiwan tends to retain less labor-intensive manufacturing onshore, along with research and development, which is where its smart machinery sector shines. As industrial robots and smart machinery learn to handle complex delicate tasks, rather than simply welding cars, it is allowing Taiwan to retain even more high-end manufacturing onshore.

Embracing Industry 4.0 in a Post-Pandemic World

The disruption of the COVID-19 pandemic is increasing the global demand for manufacturing processes that are less reliant on human laborers.

Meanwhile, the US-China trade war is seeing companies diversifying manufacturing beyond China. There is a push for the US and Europe to revitalize their own manufacturing sectors to reduce their reliance on China.

This trend also drives demand for Taiwan’s smart manufacturing technologies, says Techman Robot’s Chen:

“A limited labour pool and high land costs are a challenge in Taiwan, but smart manufacturing technologies help us overcome those challenges. The US-China trade war creates an opportunity, as Taiwan’s advances in automation, robots and cobots will allow more manufacturing to shift to Taiwan. It will also allow Taiwan to provide the technologies for smarter manufacturing around the globe.”

Taiwan’s complicated relationship with Beijing will continue to present challenges, says Victor Taichung Machinery director Wayne Hsueh. For example, it is difficult for Taiwan to participate in international agreements such as the Regional Comprehensive Economic Partnership Agreement and Free Trade Agreements. This can see Taiwan pay higher tariffs.

Despite the challenges, Taiwan’s manufacturing sector is well-placed to assist companies around the globe with embracing smart manufacturing and Industry 4.0, says Hsueh:

“These are not technologies that can be achieved overnight. However, many Taiwanese companies have been developing smart manufacturing over decades and have already achieved Industry 4.0 manufacturing.”

He then adds:

“Due to Taiwan’s manufacturing reliability and shared democratic values, Taiwan can be a key global supplier in the information and communications technology and other supply chains, such as the smart machinery industry, in the post-pandemic world.”

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)