Electro-Pneumatic Positioner TZIDC: Key Features and Specifications

Electro-Pneumatic Positioner TZIDC: Key Features and Specifications

The TZIDC Electro-Pneumatic Positioner is a highly advanced and versatile device designed for precise control of pneumatic linear or rotary actuators. This document provides a comprehensive overview of its features, operational capabilities, communication options, mounting versions, and technical specifications, highlighting its suitability for demanding industrial applications.

Overview and Core Design Principles

The TZIDC positioner is characterized by its compact design, modular construction, and excellent cost-performance ratio. It operates using 4-20 mA two-wire technology and is built for robustness, capable of withstanding a wide operating temperature range from -40 to 85°C (-40 to 185°F). A key advantage is its ease of commissioning, facilitated by a "single pushbutton" operating philosophy and fully automatic determination of control parameters, which significantly saves time and ensures optimal control behavior. The device is approved for SIL2 safety loops and holds various international certifications, including ATEX, FM, CSA, GOST, and IECEx, underscoring its reliability and compliance with stringent safety standards.

Pneumatic System and Safety Functions

The pneumatic control is managed by an I/P module coupled with a pneumatic amplifier, which accurately converts the electrical positioning signal from the CPU into a pneumatic signal for a 3/3-way valve. This system allows for continuous adjustment of air flow to the actuator, ensuring precise control and minimizing air consumption by closing the valve when the set point is reached. The TZIDC offers four distinct pneumatic versions: for single-acting or double-acting actuators, each with either a "fail-safe" or "fail-freeze" function.

Fail-safe function: In the event of an electrical power supply failure, positioner output 1 is depressurized, causing the pneumatic actuator's return spring to move the valve to a pre-defined safe position. For double-acting actuators, output 2 is simultaneously pressurized.

Fail-freeze function: If electrical power fails, positioner output 1 (and 2, if applicable) is closed, holding the valve in its current position. However, a compressed air supply failure will still depressurize the actuator.

Operation and User Interface

The TZIDC is equipped with a user-friendly operating panel featuring a 2-line LCD and four pushbuttons. This interface allows for local configuration, commissioning, and continuous operational monitoring. The "Autoadjust" function, a standard feature, enables automatic adaptation of device parameters with a simple button press, adapting to linear or rotary actuator types.

The comprehensive range of parameters includes:

Operating parameters: Signal range (4-20 mA, with split-range capability), action (increasing/decreasing signal), characteristic curves (linear, equal percentage, or custom with 20 reference points), travel limits, shut-off functions, and travel time prolongation.

Adjustment parameters: Tolerance band and dead band (sensitivity) for fine-tuning control behavior.

Monitoring parameters: Continuous detection and indication of various states, such as signal out of range, position deviation, and positioning time-out. The LCD displays critical process variables and alarms.

Diagnosis parameters: Provide insights into valve operating conditions, including the number of movements and total travel, enabling predictive maintenance. Limit values can be set to trigger alarms when exceeded.

Digital inputs allow for activation of protective functions via the process control system, while a digital output can transmit collective alarms or fault messages.

Communication and Connectivity

The TZIDC supports robust communication protocols for seamless integration into control systems.

Local Communication Interface (LKS): The standard model includes an LKS connector for direct local communication.

HART Communication: An optional HART communication module allows for communication via the 20 mA signal line.

DTM (Device Type Manager): Based on FDT/DTM technology (FDT 1.2), the DTM for TZIDC can be integrated into process control systems or used with the DSV401 (SMART VISION) program on a PC. This ensures a consistent user interface for commissioning, operation, and service, facilitating device monitoring, parameter setting, and data uploading.

LKS Adapter (RS-232 interface converter): Enables easy connection of the TZIDC to a PC for workshop or commissioning tasks.

FSK Modem: Establishes digital frequency-modulated communication with the positioner, allowing tapping at any point on the 20 mA signal line. An electrically isolated FSK modem is recommended for bus compatibility and safe operation in hazardous areas.

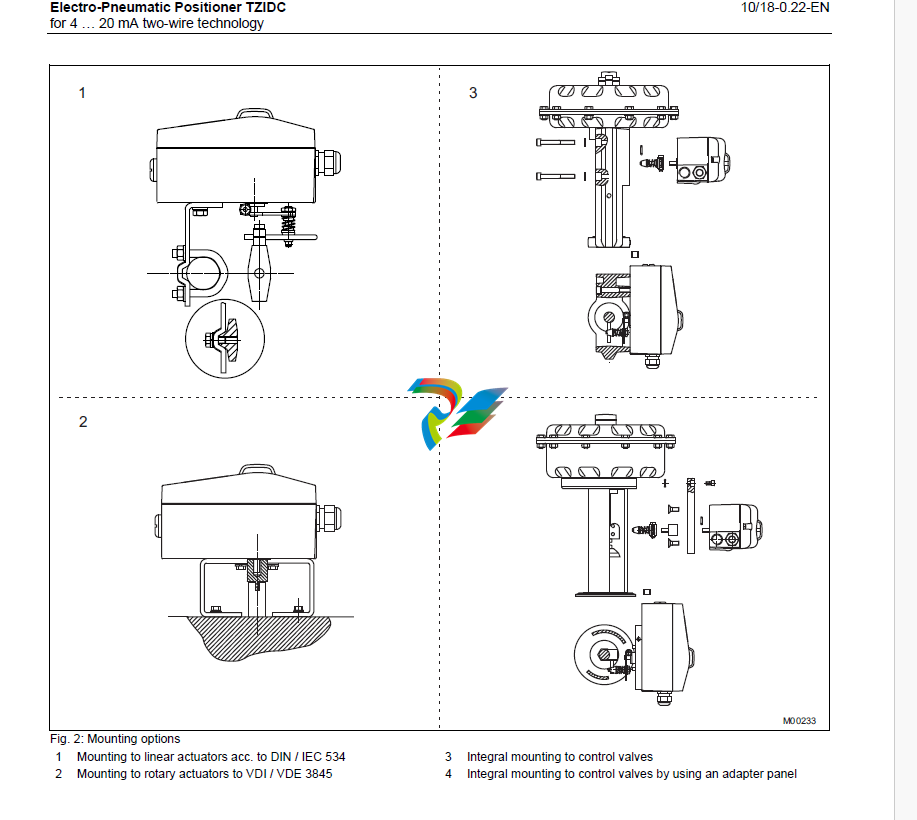

Mounting and Modular Expandability

The TZIDC positioner offers flexible mounting options to suit various actuator types:

Linear Actuators: Lateral attachment in accordance with DIN/IEC 534 (NAMUR).

Rotary Actuators: Mounting designed for VDI/VDE 3845 standard.

Integral Mounting: Suitable for direct integration with control valves, offering protected stroke measurement and internal linking, thus eliminating external tubing.

Special Actuator-Specific Mounting: Custom attachment solutions are also available.

The modular design allows for future enhancements through retrofitting optional equipment. These include plug-in modules for analog or digital position feedback and a shutdown module. Additionally, mechanical position indicators, proximity switches, or 24 V microswitches can be installed for independent position signaling.

Technical Specifications and Environmental Capabilities

The TZIDC boasts impressive technical specifications:

Input: 4-20 mA two-wire technology, with a nominal range and configurable split ranges (20-100%). Digital input for control voltages (0-5V DC for logic "0", 11-30V DC for logic "1").

Output: Compressed air output ranging from 0-6 bar (0-90 psi), with air capacities up to

( 10Nm3/h or6.0sfcm ) at 6 bar supply pressure. Digital output for control circuits.Travel: Rotation angles of 25-120° (optional 270° for rotary actuators) and travel limits of 25-60 mm for linear actuators.

Air Supply: Requires instrument air free of oil, water, and dust (acc. to DIN/ISO 8573-1), with a supply pressure of 1.4-6 bar (20-90 psi). Air consumption is minimal, less than

0.03kg/h (0.015scfm ).Performance: Characteristic deviation

≤0.5% , adjustable tolerance band (0.3-10%), and dead band (0.1-10%). Resolution is greater than 4000 steps with a sample rate of 20 ms.Environmental: Operates reliably in ambient temperatures from -40 to 85°C (-40 to 185°F) and relative humidity of 95% (annual average, condensation permissible). The housing is made of aluminum with IP 65 / NEMA 4X protection, featuring an electrostatic dipping varnish. It meets seismic requirements of DIN/IEC 68-3-3 Class III and is unaffected by mounting orientation.

The TZIDC positioner is a robust, flexible, and high-performance solution for precise pneumatic actuator control in diverse industrial environments, backed by comprehensive safety certifications and advanced communication capabilities.

.jpg)