Introduction to the Digital 02-168112-00

The Digital 02-168112-00 is a state-of-the-art industrial control system designed for high-precision automation applications. Engineered with cutting-edge technology, this digital controller offers exceptional performance, reliability, and versatility for modern manufacturing environments.

In an era where manufacturing precision and efficiency are paramount, the Digital 02-168112-00 stands out as a premium control solution for facilities looking to maximize productivity while maintaining stringent quality standards.

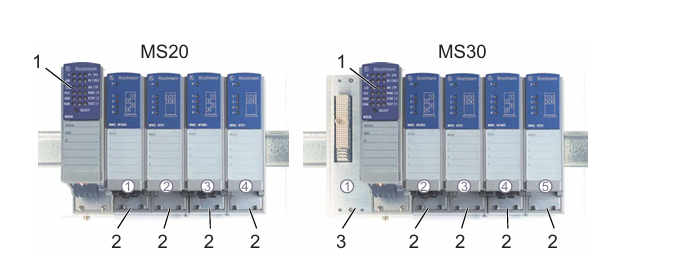

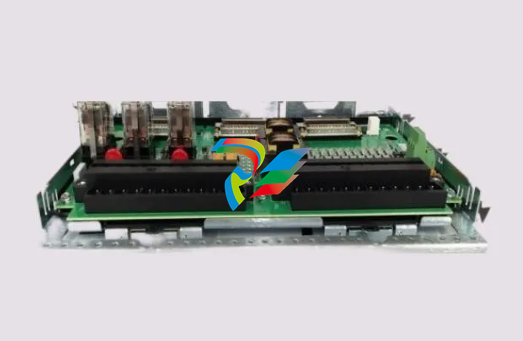

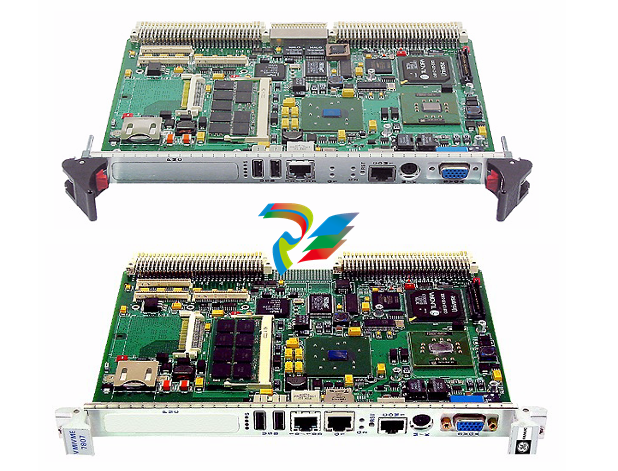

System Architecture

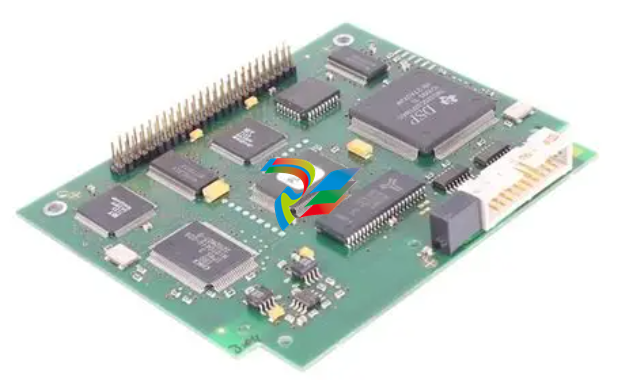

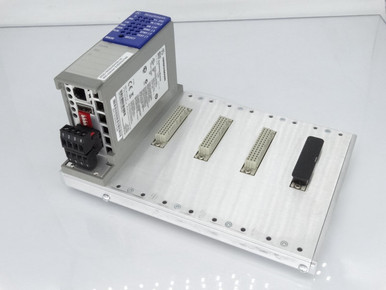

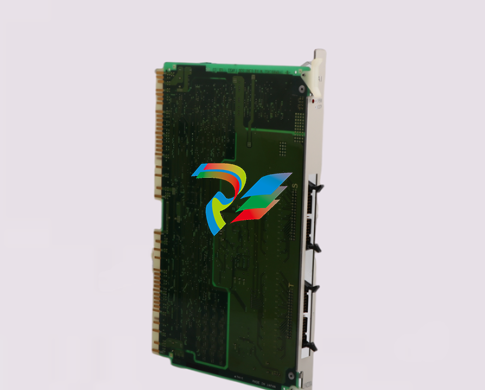

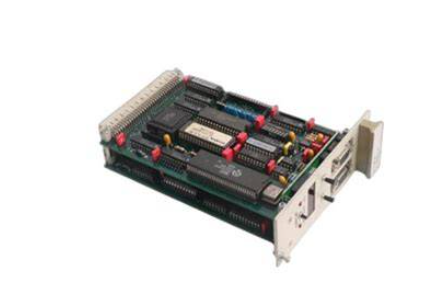

At the heart of the Digital 02-168112-00 is a modular architecture designed for flexibility, scalability, and future-proofing. The system employs a multi-processor design with dedicated subsystems for various control functions.

Core Components

High-performance dual-core processor with hardware acceleration

Integrated FPGA for real-time signal processing and I/O handling

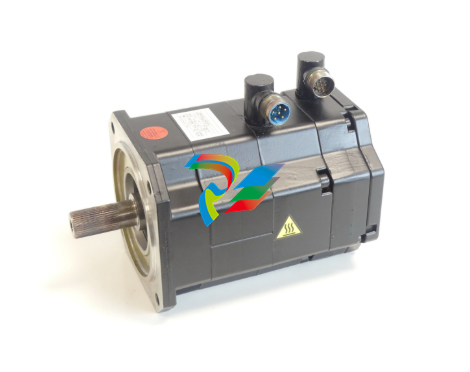

Dedicated motion control processor supporting up to 32 axes

Advanced memory architecture with ECC protection

Integrated security coprocessor for encrypted communications

This distributed processing approach allows the controller to handle complex automation tasks with deterministic timing and exceptional reliability, even in demanding industrial environments.

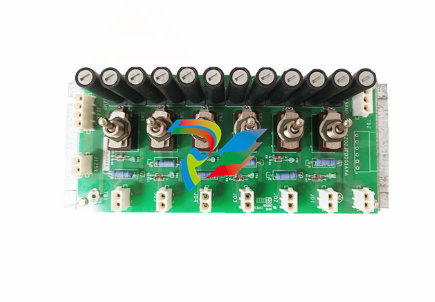

Technical Specifications

The Digital 02-168112-00 offers industry-leading specifications that enable precise control across diverse industrial applications:

| Specification | Value |

|---|---|

| Processor | Dual-core ARM Cortex-A72, 1.8GHz |

| Memory | 4GB DDR4 RAM with ECC |

| Storage | 32GB industrial-grade SSD |

| I/O Capacity | Up to 1024 digital I/O points |

| Analog I/O | 128 channels (16-bit resolution) |

| Control Cycle | 125μs minimum (adjustable) |

| Communication | Ethernet, EtherCAT, Profinet, DeviceNet, Modbus |

| Operating Temperature | -10°C to 55°C |

| Protection Rating | IP65 (front panel) |

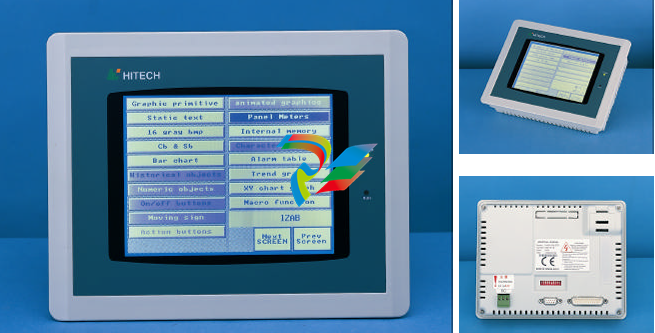

Interface and User Experience

The Digital 02-168112-00 features an intuitive user interface designed to streamline operation while providing access to the controller's advanced capabilities. The system balances simplicity with depth, allowing both new operators and experienced engineers to work efficiently.

The controller features a 10.1" high-resolution touchscreen display with 1280×800 resolution and multi-touch support, providing excellent visibility in various lighting conditions.

Operators can configure the interface layout to match specific workflow requirements, with the ability to save and recall multiple configurations for different applications or users.

The interface employs a context-sensitive navigation system that presents relevant controls and information based on the current operation, reducing complexity and minimizing the learning curve.

The system supports 12 languages with real-time switching, facilitating deployment in global manufacturing environments with diverse workforces.

Advanced Visualization

Beyond basic operation, the Digital 02-168112-00 offers sophisticated visualization capabilities, including real-time process monitoring, trend analysis, and customizable dashboards. These features provide operators and managers with immediate insight into system performance and process quality, enabling proactive optimization and troubleshooting.

Programming and Configuration

The Digital 02-168112-00 supports multiple programming methodologies to accommodate diverse application requirements and user preferences:

IEC 61131-3 compliant programming (LD, FBD, ST, IL, SFC)

Advanced motion control programming with specialized function blocks

Visual programming interface for rapid application development

C/C++ API for custom algorithm implementation

Python scripting support for system automation and data handling

This programming flexibility allows engineers to implement complex control strategies using familiar tools and approaches, reducing development time and ensuring optimal system performance.

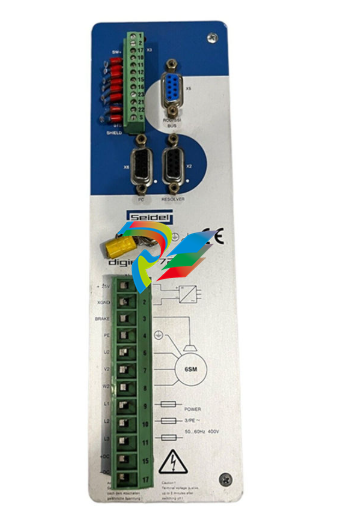

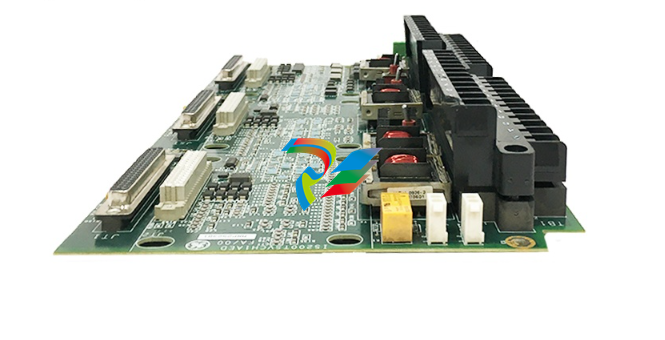

Connectivity and Integration

In today's connected manufacturing environment, the Digital 02-168112-00 offers extensive connectivity options for seamless integration with broader factory systems:

Communication Protocols

Industrial Ethernet (EtherCAT, Profinet, EtherNet/IP)

Legacy fieldbus support (Profibus, DeviceNet, CANopen)

OPC UA server for standardized data exchange

MQTT client for IoT integration

RESTful API for web-based applications

Data Management

The controller features robust data collection, storage, and analysis capabilities, including: