Distributed Control Systems LifeCycle Parts Services

4.In most cases, you can also verify your choice by viewing a photograph of the part in question. In addition, several sort and search functions simplify the information management for you

5.To get access, please contact your local ABB office.

The myABB/ My Control System customer self-service tool, available 24/7, offers you a single point of online access to information, services and service contacts for the ABB family of control systems and all ABB products.

You’ll quickly find that new MyABB/ My Control System web portal is a great way to increase your productivity, minimize cost, and extend the useful life of your ABB control products and systems.

My Control System is a valuable source for maintenance information and for enhancement of the control system and provides ready answers to frequently asked questions, thus reducing the effort spent looking for information and shortening software delivery times. All relevant ABB control system information is in one place and just a couple of mouse clicks away. A basic version of My Control System (limited access) will be provided to all ABB customers.

Automation Sentinel subscribers will enjoy premium access, which includes features such as software downloads, access to validated security updates and documentation already filtered for each system.

Automation Sentinel Automation Sentinel is ABB’s subscription based control system lifecycle management and support program that assists system owners to actively manage their control system lifecycle, support and maintenance.

With this program, system owners can keep their control software up-to-date and maintain a flexible path forward to new system software technology. Automation Sentinel provides exclusive services for the maintenance, evolution and continual enhancement of the installed base of ABB control systems.

System LifeCycle Fingerprint Report System Lifecycle Fingerprint, available for ABB control system customers with an myABB/My Control System account together with a Fingerprint license, provides a comprehensive strategic maintenance analysis of the installed ABB control system hardware. It extends the service of System Lifecycle Benchmark, with the benefit of providing the full scope of analysis and recommendations for taking actions.

Based on computer aided data collection from the installed ABB control system, an analysis and evaluation is performed by an ABB Field Service engineer. As a result, a System Fingerprint report is then presented by ABB Field Service authorities.

Based on the life-cycle status of the individual installed units and ABB Field Service Engineer's experience with the customer plant, an evaluation will be conducted leading to a strategic hardware maintenance plan.

In addition to the current lifecycle status of the installed devices, the System Lifecycle Fingerprint report provides an easy to read table summary of the forecast lifecycle for the installed devices, and briefly summarizes key findings and recommended actions, helping to avoid unwelcome failures and production losses

Spare parts

Spare Parts Service Spare parts are essential in maintaining a high system availability. The Spare Parts Services supplies brand new certified ABB spare parts shipped within a day, increasing reliability and leading to longer lifetime of your equipment.

With our large stock of ABB spare parts for all of ABB’s different control systems, we offer quick handling and shipping of your spare parts needs through our 24 hours web-based ordering process. The use of optimal means of transport results in cost-effective and quick arrival of your spare parts.

Emergency Parts Service For occasions when quickest possible delivery is the most important factor, we offer the Emergency Parts Service.

Spare Parts service availability is critical to on-going operations, not only during business hours. ABB maintains a complete stock of certified ABB parts to ensure availability

For emergency cases, our personnel and partners are available 24 hours to provide immediate response to your emergency parts request and our global logistics network ensures the quickest possible delivery.

Refurbished Parts Service For cases when new spares a no longer manufactured or no longer available, or when if you need to acquire a brand new spare part in the most cost-effective way

The Refurbished Parts Service is a cost-effective alternative to purchasing new spare part modules. Parts sold with this service are ‘like-new’ parts, recovered and updated by ABB. What’s more, the have been tested to meet the original equipment specifications and the current component standards.

Repair, exchange and testing

Parts Repair Service When the need is to have a unique individual module repaired and returned back to the plant, we offer the Parts Repair Service.

Our repair network provides repairs that meet original equipment specifications. Our world-class turnaround time for repairs is typically less than two weeks, and a repair report in is included every return shipment, detailing what steps has been taken during the repair process.

Parts Exchange Service For when you wish to purchase a fully functional spare in return for your broken unit.

Parts Exchange Service keeps lead-times to a minimum while offering a cost-efficient alternative to a spare part. Parts under this service can be refurbished or new, depending on availability. When refurbished units are provided, keep in mind that they are ‘like-new’ parts, recovered and updated by ABB.

A repair report for the broken ‘sent-in’ unit can be supplied if it is repaired. Request this report when ordering the exchange part.

Parts Test Service Choose this service when you want assurance that the spares you have used or stored for a longer period are still operational.

Parts Test Service determines the status of parts, e.g. if they are functional and meet the original manufacturing specifications, with a 3-week turnaround time or less. Units that passes the test are re-sealed with factory labels to provide the best performance when placed in your system. ABB Parts Repair Service is available for any non-functioning units. A Test Report is always included with the unit.

Parts management program, upgrades and parts analysis

Preventive Maintenance Kits Choose this program when you want to secure continuing operation and know the calculated maintenance cost.

Preventive maintenance is the most efficient maintenance program because it ensures that equipment is serviced before a breakdown actually occurs. Preventive maintenance is carried out during planned productions shutdowns and the required parts and resources should be reserved in advance.

Our pre-specified, easy-to-order kits consist of genuine ABB spare parts that are necessary for a specific scheduled maintenance. These cost-efficient kits have a lower price compared to the price of individual spare parts and are delivered to a lead-time, unlike normal spare parts.

inventory Access™ Program Choose this program when you want to have spare parts located at or near your premises.

Our Parts Inventory Management program, inventory Access™ (iAP), is a cost-effective alternative to purchasing parts inventory. It provides a customized spare parts inventory at or near your location yet owned and maintained by ABB.

We take full responsibility for obsolescence, depreciation, administration and inventory ownership costs until the parts are put into service

A fixed monthly fee gives you the security of on-site parts availability, while reducing the initial capital expenditures for a spare parts inventory. Actual purchase does not take place until the part is taken out from the Inventory Access part stock.

This is also the time at which the warranty period starts. The inventory Access™ Program is offered on request. Please contact you local ABB representative for further information

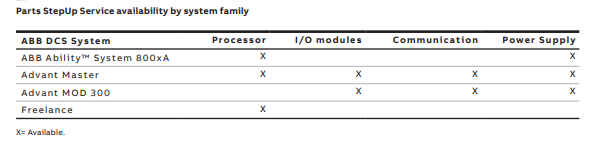

Parts StepUp Service Choose this service when you need to exchange outdated hardware or current processor modules for new, unused, fully supported hardware of latest design and different types with higher performance, extending your system parts life cycle.

Your hardware is supported with a suite of Parts Services. For legacy hardware in later life cycle phases, availability of services cannot be guaranteed, although ABB will always offer support with our best effort. Actively supported processor modules may be struggling with an increased system and processor load after a commissioning or a system expansion

With the Parts StepUp service it’s possible to replace legacy hardware for new fully supported and to replace processor modules with newer and more powerful versions, increasing reliability, lifetime and system stability. The new parts are typically delivered after two working weeks, and the replaced parts shall be returned to ABB no later than 90 days from the delivery of the StepUp parts.

Parts StepUp is a cost effective way of increasing the processing power of your system and replacing old hardware. Combined with Automation Sentinel, ABB’s control systems life cycle management program, there is an even greater price incentive: It is the most cost efficient way of upgrading your system hardware and increasing controller processor power compared to any other way of acquiring brand new certified ABB DCS parts.

Parts Root Cause Analysis Service Choose this service to determine the root cause of failed hardware.

When your hardware fails it’s sometimes most important to determine the cause of the failure. The Parts Root Analysis Service does just that – ABB’s experienced hardware design expert’s uses their unique knowledge combined with access to original design and test documentation to find the root cause of the failure through extensive analysis of your failed unit

After the analysis, we provide a complete status report of the faulty unit, including analysis and manufacturer information, results from functional tests, probable fault causes and finally the required and/or recommended actions.

A repair of the failed unit is not included in the Parts Root Cause Analysis Service and depending on the type of failure a repair might not be possible to perform. Furthermore, the unit must mot have been subject to repair attempts or otherwise manipulated, if so we cannot analyze the unit

The service is available for ABB Ability™ System 800xA hardware and Advant Master and MOD 300 hardware in the Active life cycle phase. For product families in later life cycle phases, availability is determined case-by-case

The Root Cause Analysis Service is in many cases the best and most cost effective way to find the real cause of a unit failure. For customers with Automation Sentinel, ABB’s control systems life cycle management program, this service will be discounted, but cannot be combined with other Automation Sentinel discounts

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)