ABB machinery drives ACS850

ABB machinery drives ACS850 0.37 to 560 kW/0.5 to 700 hp Catalog

Selecting and ordering your drive

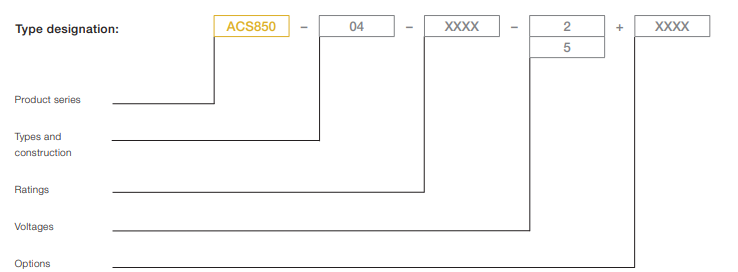

Type designation is a unique reference number that clearly identifies the drive by construction, power and voltage rating and selected options. Using the type designation you can specify your drives from the wide range of options available. Options are added to the type designation using the corresponding “plus” (+) code.

Build up your own ordering code using the type designation key below or contact your local ABB drives sales office and let them know what you want. Use page 3 as a reference section for more information.

ntroduction to ACS850

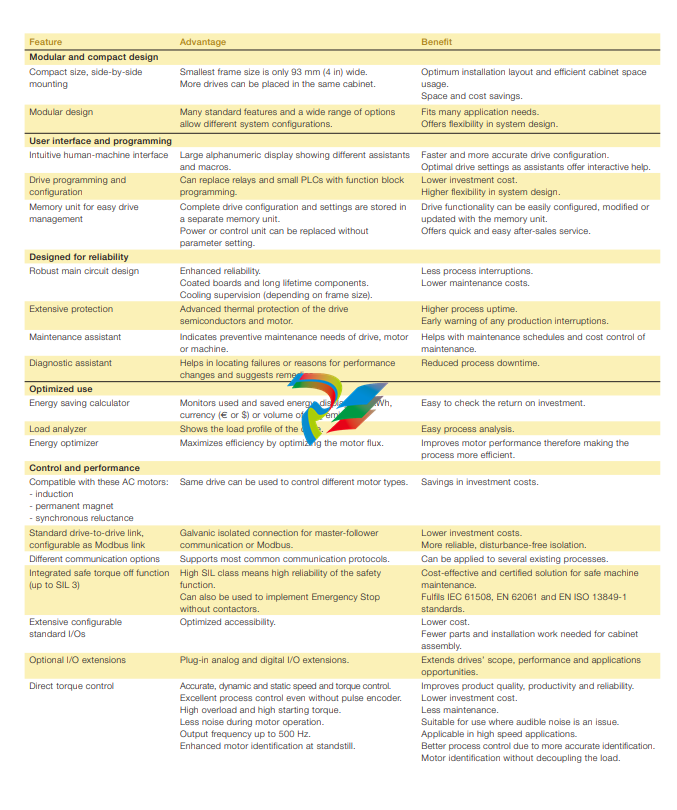

ABB machinery drives are designed to meet the production and performance needs of machine builders, system integrators, panel builders and end users in a broad range of applications. ACS850 drives are ideal for applications like cranes, extruders, conveyors, winders, pumps, fans and mixers in industries such as material handling, plastic and rubber, food and beverage, textile and metals.

The drives can be configured to meet the precise needs of industries and order-based configuration is an integral part of the offering. Covering a wide power and voltage range with standard and optional features, the drives are readily programmable, making their adaptation to different applications easy.

Wide range of options ACS850 drives offer a wide range of built-in options such as different I/O and communications. A wide selection of external accessories is also available. The flexibility and programmability of the drives make them suitable for many applications in different industries.

Robust design The current ratings of ABB machinery drives are designed for applications that have a high overload requirement. At the heart of the drive is the motor control platform, direct torque control (DTC) that provides accurate motor torque and speed control even without feedback. The drive is designed for a long working life and as such, parts like fans and capacitors are selected to maximize their lifetime. This, together with the extensive protection features and design details such as coated boards, results in excellent reliability for the demanding industrial market.

Optimized cabinet assembly ACS850 drives are designed to be built into a customer’s own cabinet, using minimal cabinet space while ensuring that cabinet assembly is as easy as possible. The drives can be mounted side-by-side and cabinet assembly documentation is included. The documentation gives examples of different cabinet configurations, examples of drawings and hints on the selection of auxiliary equipment.

Based on direct torque control technology, the ACS850 offers highly advanced features. The ACS850 standard control program provides solutions to virtually all AC drives applications such as mixers, separators, extruders and conveyors

Fast and easy commissioning The ACS850 standard control program offers flexibility and extensive parameter settings. It consists of a simple, readymade program that can easily be modified to meet specific application needs. Commissioning is also simplified by several standard software features.

Pre-programmed protection functions A wide range of features provide protection for the drive, motor and the process: − Ambient temperature − DC overvoltage − DC undervoltage − Drive temperature − Input phase loss − Overcurrent − Power limits − Short circuit

Programmable protection functions: − Adjustable power limits − Control signal supervision − Critical frequencies lock-out − Current and torque limits − Earth fault protection − External fault − Motor phase loss − Motor stall protection − Motor thermal protection − Motor underload protection − Panel loss

Program customization In addition to standard control program functionalities the ACS850 offers function block programming which makes it possible to replace relays or even a PLC

Removable memory unit A removable memory unit provides easy maintenance by storing the complete firmware including all user settings and motor data. Thus, if the power unit or control unit is replaced, the drive can be re-commissioned without any reprogramming, just by moving the memory unit.

The removable memory unit: − Stores the drive software and parameter settings − Allows fast and easy recommissioning − Enables software and parameter configuration at workshop instead of doing it on-site

The features of ACS850 drives are designed to enhance their reliability and durability as well as the easiness of use. Also several advanced functions make the drives easy to use. These functions can be accessed either via the user-friendly assistant control panel or DriveStudio PC tool.

Macros Several macros which have pre-set, application-specific parameter settings are available as standard in each drive. These pre-programmed parameter settings enable fast and easy commissioning by adjusting all the relevant parameters in just a couple of clicks

Startup assistant The intelligent and intuitive startup assistant allows first time users to quickly get up to speed and customize the drive according to their needs. This is complemented by a built-in help function to make parameter-by-parameter setting easy. This way the drive can be quickly commissioned, even without manuals

Maintenance assistant The maintenance assistant reminds the user about the drive’s preventive maintenance schedule or routine, or that of its associated components such as motor, cabinet air

inlet filters and input contactors. It reminds users of planned maintenance needs based on running hours, operating hours or relay switching to reduce unplanned process interruptions.

Diagnostic assistant Each ACS850 drive is equipped with a diagnostic assistant that helps in locating the cause of any disturbance to the drive and even suggests possible remedies. This reduces process downtime by making repair or adjustments quicker and easier.

Energy saving features − A calculator showing the used and saved energy, displayed in kWh, currency (€ or $) or volume of CO2 emission. Data is calculated by reference values stored in the drive by the user. − An energy efficiency optimizer that adjusts the motor flux in such a way that the total efficiency is maximized. − A load analyzer showing the load profile of the drive.

Short/long menus The user interface can be configured so that it displays only the most common parameters. This short menu allows users to quickly access the parameters they need without having to go through all the drive parameters.

A long menu is available, displaying a complete list of parameters for a more advanced configuration.

Input and output mapping This functionality allows the user to easily go through the input and output configuration of the drive.

List of changed parameters The feature allows users to go through the list of changed parameters. This way the user does not have to go through all the drive parameters making it quick to identify the recently modified ones.

Options Remote monitoring and diagnostic toolsSREA-01 enables remote access With drives increasingly being installed in remote locations, it is vital that operational and process data is monitored locally in real time and transmitted to a central location for analysis. Often there is no qualified service personnel stationed at these sites, which makes remote monitoring and diagnosis of the drive and application crucial to process availability. The SREA-01 Ethernet adapter performs all these remote access tasks.

Designed as an optional remote interface module for the drives, the SREA-01 can send process data, data logs and event messages independently, without a PLC or a dedicated on-site computer, and has an internal web server for configuration and drive access.

Connecting multiple drives to an Ethernet or GPRS network In addition to a standard Ethernet port, the SREA-01 has a serial port for connection to a standard GSM/GPRS modem for Internet connectivity in isolated places. The modem connection enables sending e-mail or SMS messages, uploading data fi les by FTP, or accessing the SREA-01 web pages.

The SREA-01 is connected to the panel port, or alternatively to the Modbus interface, of a drive. A maximum of 10 drives can be connected to a single SREA-01 module over Ethernet or EIA-485 serial communication networks. Simultaneous use of the two connection methods is possible, allowing access to different types of drives. In addition, Modbus TCP commands from a PLC to a drive are supported in the remote monitoring mode.

The SREA-01 is connected to the panel port, or alternatively to the Modbus interface, of a drive. A maximum of 10 drives can be connected to a single SREA-01 module over Ethernet or EIA-485 serial communication networks. Simultaneous use of the two connection methods is possible, allowing access to different types of drives. In addition, Modbus TCP commands from a PLC to a drive are supported in the remote monitoring mode.

The collected data logs can be sent by e-mail or FTP, either through a local area network or the Internet. The sending interval can be configured by the user with logs sent, for example, hourly or weekly. In addition to its data logging functionality, the SREA-01 also has an internal Modbus TCP gateway, providing a standard interface that can be used by supervisory control and data acquisition (SCADA) applications to display drive information in real time.

Receiving event messages and alarms, and accessing the drive remotely The SREA-01 can be used to monitor the drive and application parameters such as process temperatures, and send alarm messages to maintenance personnel if a set limit is exceeded. Event and alarm messages are sent as SMS messages or by e-mail using the user´s own messages. The event conditions and messages can be configured by the user to make them suitable for a number of applications.

At any time, the internal web server of the SREA-01 provides an intuitive user interface for accessing the drives. Travel to sites can often be avoided by using a standard web browser to view and change the drive parameters, monitor the status of all connected devices, and browse the actual faults or history of the installation.

.png)

.png)

.png)