ABBDistributed busbar protection REB500 including line and transformer protection Product Guide

Three-phase voltage plausibility

This function is used for checking the sum and

the phase sequence of the three-phase voltages.

Additional

features

Self-supervision

All the system functions are continuously

monitored to ensure the maximum reliability

and availability of the protection. In the event

of a failure, incorrect response or inconsistency, the corresponding action is taken to

establish a safe status, an alarm is given and

an event is registered for subsequent diagnostic analysis.

Important items of hardware (e.g. auxiliary

supplies, A/D converters and main and program memories) are subjected to various

tests when the system is switched on and also

during operation. A watchdog continuously

monitors the integrity of the software functions

and the exchange of data via the process bus

is also continuously supervised.

The processing of tripping commands is one

of the most important functions from the reliability and dependability point of view. Accordingly, every output channel comprises two

redundant commands, which have to be

enabled at regular intervals by a watchdog. If

the watchdog condition is not satisfied, the

channels are blocked.

Extension of the system

The system functions are determined by software, configured using the software configuration tool.

The system can be completely engineered in

advance to correspond to the final state of the

station. The software modules for new bays or

features can be activated using the HMI500

when the primary plant is installed or the features are needed.

Additional system functions, e.g. breaker failure, end fault protection or bay level

back-up / Main 2 functions can be easily activated at any time without extra hardware.

Resetting the trip commands/-signals

The following resetting modes can be selected for each binary output (tripping or signal

outputs):

• Latches until manually reset

• Resets automatically after a delay

Inspection/maintenance

A binary input is provided that excludes a bay

unit from evaluation by the protection system.

It is used while performing maintenance

respectively inspection activities on the primary equipment.

Redundant power supplies (Option)

Two power supply modules can be fitted in a

redundant arrangement, e.g. to facilitate

maintenance of station batteries. This is an

option for the central unit as well as for the

bay unit.

Time synchronization

The absolute time accuracy with respect to an

external time reference depends on the

method of synchronization used:

• no external time synchronization:

accuracy approx. 1 min. per month

• periodic time telegram with minute pulse

(radio or satellite clock or station control

system): accuracy typically ±10 ms

• periodic time telegram as above with second pulse: accuracy typically ±1 ms

• a direct connection of a GPS or DCF77 to

the central unit is possible: accuracy typically ±1 ms

• Furthermore, the time synchronization can

be done, if available, via the interbay bus

IEC103, LON or SNTP (in case IEC61850-

8-1 is used)

The system time may also be synchronized by

a minute pulse applied to a binary input on the

central unit.

Distributed busbar protection REB500

including line and transformer protection

Page 17

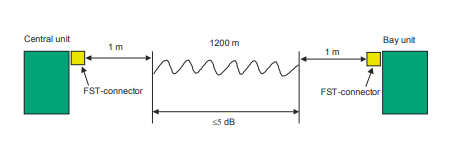

Requirements Optical fiber cables

A distributed busbar protection layout requires optical fiber cables and connectors with

the following characteristics:

• 2 optical fiber cores per bay unit

• glass fibers with gradient index

• diameter of core and sheath 62.5,

respectively 125 m

• maximum permissible attenuation 5 dB

• FST connector (for 62.5 m optical fibers)

• rodent protected and longitudinally waterproof if in cable ducts

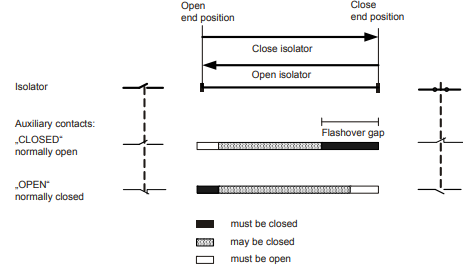

Isolator auxiliary contact

Auxiliary contacts on the isolators are connected to binary inputs on the bay units and

control the status of the busbar replica in the

numerical busbar protection.

One potentially-free N/O and N/C contact are

required on each isolator. The N/O contact

signals that the isolator is “CLOSED” and the

N/C contact that the isolator is “OPEN”. During the closing movement, the N/O contact

must close before the isolator main contact

gap reaches its flashover point.

Conversely, during the opening movement,

the N/O contact must not open before the isolator main contact gap exceeds its flashover

point.

If this is not the case, i.e. the contact signals

‘no longer closed’ beforehand, then the N/C

contact may not signal “OPEN” before the

flashover point has been exceeded.

Distributed busbar protection REB500

including line and transformer protection

Circuit-breaker replica

When the circuit-breaker replica is read in the

feeder or the bus-tie breaker, the circuitbreaker CLOSE command must also be connected.

Main current transformer

The algorithms and stabilization features used

make the busbar protection largely insensitive

to CT saturation phenomena. Main CTs types

TPS (B.S. class x), TPX, TPY, 5P.. or 10P.. are