GE PQM II Power QualIty Meter

PQM II Power QualIty Meter

Power quality metering with waveform capture and

historical data logging

• Easy to program and use with keypad and large illuminated

40 character display

• Multiple communication ports for integration with DCS and

SCADA systems

aPPlICatIons

• Supports DNP 3.0 and Modbus protocols

• Digital and analog I/Os for control and alarms

• Voltage disturbance recording capability for electrical

sag and swell events.

• Metering of distribution feeders, transformers, generators,

capacitor banks and motors

• Medium and low voltage systems

Features

Features

• Commercial, industrial, utility

• Flexible control for demand load shedding, power factor, etc.

Monitoring and Metering

• Ia Ib Ic In

• Va Vb Vc Vab Vbc Vca

• V I unbalance

• True PF crest and K factor

• Hz W var VA

• Wh varh VAh W cost

• Demand: A W var VA

• Harmonic analysis through 63rd with THD and TIF

• Event recorder - 150 events

• Waveform capture

• Data logger -98.000 events

• Voltage Disturbance Recorder (VDR) -500 events

Communications

• Front RS232 serial port (1.200 to 19.200 bps)

• Two rear RS485 serial ports with ModBus and

DNP 3.0 protocol

• Ethernet connectivity provided by MultiNet

• EnerVistaTM software is provided for setup and

monitoring functions

• External dial-in modem capabilities

Protection & Control

• Load shedding

• Power factor control

• Pulse input totalizing

Introduction

GE Multilin has set a new standard in

metering technology with the introduction

of the PQM II. This meter, designed on

the latest industry specifications, provides

accurate and reliable three-phase power

metering with an optional Ethernet and

fiber communications module in a small

and modern package. The PQM II can

be used for a variety of applications

including metering of distribution feeders,

transformers, generators and motors.

robust Metering and Power Quality

Capabilities in one Package

Digital Metering

The PQM II is an ideal choice when

continuous monitoring of a three phase

system is required. It provides metering for

current, voltage, real and reactive power,

energy use, cost of power, power factor

and frequency. Waveform capture and

Voltage Disturbance Recorder continuously

monitors power quality. Programmable

setpoints and 4 assignable output relays

allow control functions to be added for

specific applications.

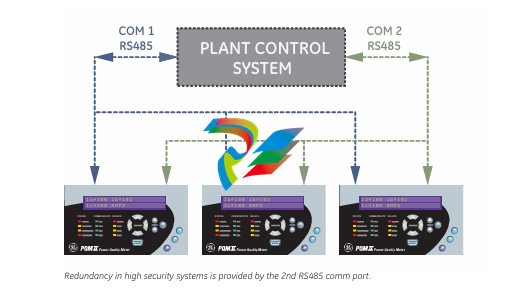

Communications Made easy

Integrate process, instrumentation

and electrical requirements in a plant

automation system by connecting PQM II

meters to a DCS or SCADA system. Meter

provides multiple communication ports that

can provide data simultaneously to multiple

masters such as SCADA, DCS, BMS etc.

Meter supports both ModBus and DNP 3.0

protocol. A computer running EnerVistaTM

software can change system setpoints,

monitor values, status and alarms.

Continuous monitoring minimizes process

downtime by immediately identifying

potential problems due to faults or

changes.

Industry leading software makes

setup simple

The PQM II comes complete with

EnerVistaTM GE Multilin's suite of software

tools for managing the entire lifecycle

implementation of the PQM II. EnerVistaTM

contains all of the tools for setting up and

configuring your PQM II in minutes via

RS232. RS485. external modem or Ethernet

LAN.

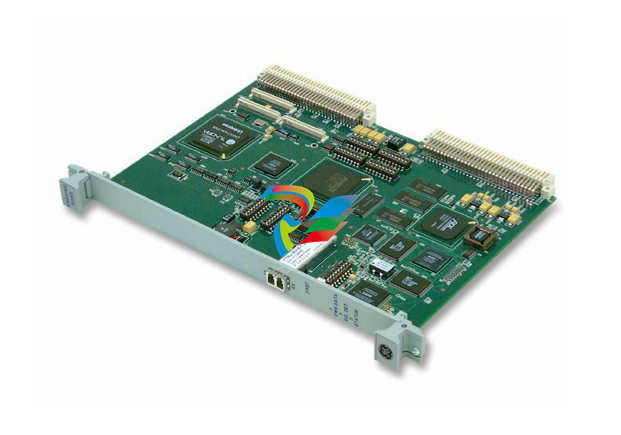

ethernet capability

With the optional Multinet module, users

can add Ethernet capability to their meter.

Multinet is an Ethernet communications

module that allows connection of up to 30

ModBus devices, providing ModBus TCP/IP

communications for these devices over

Ethernet. This allows connection to Fiber

Optic LAN and WAN systems for remote

access to data on the PQM II.

standard Features

The PQM II provides continuous monitoring

of a three-phase system. It provides

metering of current, voltage, real and

reactive power, energy use, cost of power,

power factor and frequency. Ethernet

communications are available through the

optional Multinet module.

Metering

PQM II is a true RMS meter with 0.2%

accuracy for voltage and currents. The

PQM II provides advanced features for

monitoring and metering which include:

• Ia Ib Ic In

• Va Vb Vc Vab Vbc Vca

• V I unbalance

• True PF crest and K factor

• Hz W var VA

• Wh varh VAh W cost

• Demand: A W var VA

Keypad and illuminated 40 character

dis play provides local setpoint settings and

monitoring of values and status.

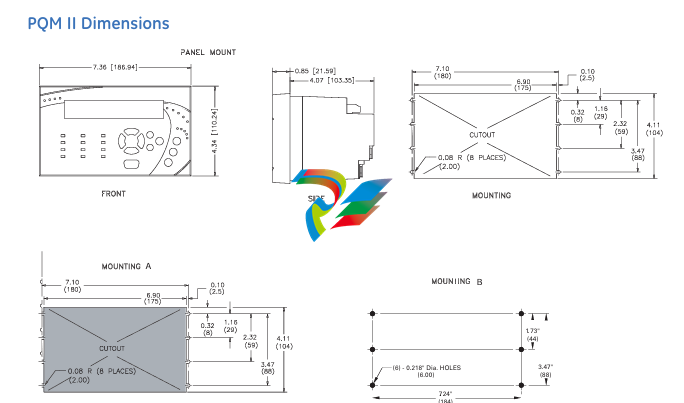

Mounting Versatility

PQM II panel mount with display, offers an

easy local interface. Standard models have

RS485 communications for programming

and monitoring. Users can replace

expensive additional devices by-adding

the CONTROL, TRANS DUCER and POWER

analysis options to the PQM II as required.

alarms

Any of the assignable outputs may be

used to trigger an alarm for specific

applications. Simple alarm messages

provide easy notification

ConDItIon

aPPlICatIon

motors/transformers

pumps/compressors

leakage/unbalance

motors

overcurrent

undercurrent

neutral current

current unbalance

overvoltage

undervoltage

phase sequence

overfrequency

underfrequency

power factor

switch input

equipment protection

motors/load transfer

pumps/equipment

generators

load shedding

capacitor banks

process control

Communications

Integrate process, instrumentation

and electrical requirements in a plant

automation system by connecting PQM II

meters to a DCS or SCADA system. Initially

PQM II meters can be used as stand-alone

units. Open architecture allows connection

to other ModBus® compatible devices

on the same communication link. At a

later stage PQM II can be integrated in a

complete plant wide system for overall

process monitoring and control.

The standard PQM II comes complete

with a rear RS485 and front RS232 port.

RS232 port can be used for data collection,

printing reports or problem analysis without

disturbing the main RS485 communication

interface at rear. The standard meter

provides:

• RS485 ModBus® 1.200 to 19.200‑bps

• DNP 3.0 Level 2 Protocol

• Mini RTU SCADA system component

• Measure actual values

• Read status

• Issue control commands

• Load all setpoints from a file

• Change individual setpoints

A computer running EnerVistaTM software

can change system setpoints, monitor

values, status and alarms. Continuous

monitoring minimizes process downtime

by immediately identifying potential

problems due to faults or changes.

Future expansion

The PQM II uses non-volatile flash memory

for firmware storage. This allows future

product upgrades to be loaded via

the serial port. Upgrades can also be

downloaded from the GE Multilin website.

options

There are a variety of options available

to the user, allowing a range of custom

configurations:

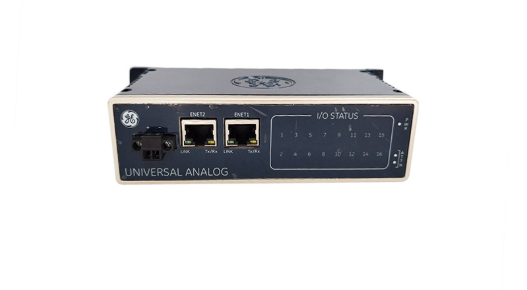

transducer

Four analog outputs: Four isolated analog

outputs can be used to replace eight

analog transducers. Output signals can

be selected from any of the measured

parameters for direct interface to a PLC or

other devices.

analog Input: PQM II meter can accept

two analog inputs from external devices.

Meter can be programmed to activate a

control relay based on analog input from

transducers (temperature, level etc.)

Communications

second rear Comm Port: An additional

rear RS485 comm port is provided for

simultaneous monitoring by process,

instrument, electrical or maintenance

personnel.

Control

Three output relays and four inputs allow

measured parameters from the standard

PQM II to be combined with setpoints

and I/Os for control applications. With the

control option, three output relays and

four switch inputs are added along with

programmable set points to make

a mini RTU. Output relays can also be

controlled via the communication port or

assigned to different setpoints for custom

programming to accommodate many

applications such as:

• Undercurrent alarm for pumps

• Over and undervoltage for generators

• Unbalance alarm for rotating machines

• Dual level power factor for capacitor

bank switching

• Underfrequency/demand output for

load shedding resulting in power cost

savings

• kWh, kvarh and kVAh pulse output for

PLC interface

Power analysis

Data Logger (Trending): Trending is

useful as a trouble shooting aid when a

problem is detected. Measured values

can be selected and plotted with a

programmable sampling rate to suit the

time interval of interest. The generated

chart recorder screen can be printed or

exported to other programs for report

writing.

Harmonic analysis: Non linear loads such

as variable speed drives, computers and

electronic ballasts can cause harmonics

which may lead to problems such as

nuisance breaker tripping, telephone

interference, transformer, capacitor or

motor overheating. Harmonic analysis

can be used for fault diagnosis such as

detecting undersized neutral wiring, need

for a harmonic rated transformer, or

effectiveness of harmonic filters. Details

of the harmonic spectrum are useful and

available with the power analysis option.

Voltage Disturbance recorder (VDr)

Digital Metering

The Voltage Disturbance Recorder (VDR)

function adds to the PQM II the ability

to monitor and record Sag and Swell

disturbances. It can record up to

500 sag/swell events for all voltages

simultaneously.

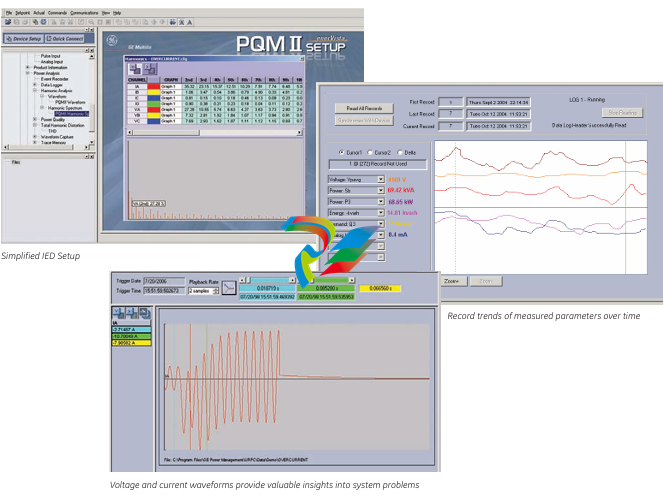

enerVistaTM software

waveform Capture: Voltage and current

waveforms can be captured and displayed

on a PC using the EnerVistaTM program

supplied with the PQM II or using third

party software. Distorted peaks or notches

from SCR switching provide clues for taking

corrective action.

event recorder: Alarms, setpoint triggers,

input and output events can be stored

in a 150 event record and time and date

stamped by the internal clock. This is

useful for diagnosing problems and

system activity. Minimum and maximum

values are also continuously updated and

time stamped.

trace Memory: The PQM II can be

configured to record a maximum of 36

cycles of data on all voltage and current

inputs based on overvoltage, undervoltage,

overcurrent or switch input state change.

enerVistaTM launchpad

EnerVistaTM Launchpad is a powerful

software package that provides users with

all of the setup and support tools needed

for configuring and maintaining GE Multilin

Products. Launchpad allows configuration

of devices in real-time by communicating

using RS232. RS485. Ethernet, or modem

connections.

The intuitive user interface makes it simple

to enter setpoints, read metered values,

monitor status and evaluate power quality.

Powerful troubleshooting features make it

easy to retrieve and view voltage & current

waveshapes and harmonic analysis.

This vital information can help provide

early warning of problems and prevent

equipment damage or nuisance breaker

tripping.

enerVista launchpad PQM II setup and analysis

PQM II setup program contains many tools and reports that simplify device configuration and allows viewing of power system events.

Included in Launchpad is a document

archiving and management system

that ensures critical documentation is

up-to-date and available when needed

by automatically checking for and

downloading new versions of manuals,

applications notes, specifications, and

service bulletins.

Viewpoint Monitoring

Viewpoint Monitoring is a simple-to

use, full-featured monitoring and data

recording software package for small

systems. Viewpoint Monitoring provides a

complete HMI package that instantly puts

critical real-time device data on your PC

through pre-configured graphical screens

with the following functionality.

• Plug‑&‑Play Device Monitoring

• System Single‑Line Monitoring &

Control

• Annunciator Alarm Screens

• Trending Reports

• Automatic Event Retrieval

• Automatic Waveform Retrieval

enerVistaTM Integrator

EnerVistaTM Integrator is a toolkit that

allows seamless integration of GE Multilin

devices into new or existing automation

systems by sending GE device data to

HMI, DCS, and SCADA systems. Included in

EnerVista Integrator is:

• OPC/DDE Server

• GE Multilin Drivers

• Automatic Event Retrieval

• Automatic Waveform Retrieva

.jpg)