ABBDCS800 Hardware Manual DCS800 Drives (20 to 5200 A)

avoid damage and injury.

WARNING!

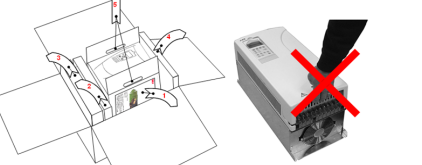

• DCS800 sizes D4 ... D7: The drive is heavy. Do not lift it alone. Do not lift the

unit by the front cover. Place units D4, D4+ and D5 only on their back.

DCS800 sizes D5 ... D7: The drive is heavy. Lift the drive by the lifting lugs

only. Do not tilt the unit. The unit will overturn from a tilt of about 6 degrees.

• Make sure that dust from drilling does not enter the drive when installing.

Electrically conductive dust inside the unit may cause damage or lead to

malfunction.

• Ensure sufficient cooling.

• Do not fasten the drive by riveting or welding

Operation

These warnings are intended for all who plan the operation of the drive or operate

the drive. Ignoring the instructions can cause physical injury or death and/or damage

to the equipment.

WARNING!

• Before adjusting the drive and putting it into service, make sure that the motor

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at

speeds above and below the base speed.

• Do not control the motor with the disconnecting device (disconnecting mains);

instead, use the control panel keys and , or commands via the I/O

board of the drive.

• Mains connection

You can use a disconnect switch (with fuses) to disconnect the electrical

components of the drive from the mains for installation and maintenance work.

The type of disconnect switch used must be as per EN 60947-3, Class B, so as

to comply with EU regulations, or a circuit-breaker type which switches off the

load circuit by means of an auxiliary contact causing the breaker's main

contacts to open. The mains disconnect must be locked in its "OPEN" position

during any installation and maintenance work.

• EMERGENCY STOP buttons must be installed at each control desk and at all

other control panels requiring an emergency stop function. Pressing the STOP

button on the control panel of the drive will neither cause an emergency stop of

the motor, nor will the drive be disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in case of any

imminent danger according to the standards in the safety instructions it is not

sufficient to merely shut down the drive via signals "RUN", "drive OFF" or

"Emergency Stop" respectively "control panel" or "PC tool".

• Intended use

The operating instructions cannot take into consideration every possible case

of configuration, operation or maintenance. Thus, they mainly give such advice

only, which is required by qualified personnel for normal operation of the

machines and devices in industrial installations.

If in special cases the electrical machines and devices are in-tended for use in

non-industrial installations - which may require stricter safety regulations (e.g.

protection against contact by children or similar) - these additional safety

measures for the installation must be provided by the customer during

assembly.

Note:

• When the control location is not set to Local (L not shown in the status row of

the display), the stop key on the control panel will not stop the drive. To stop

the drive using the control panel, press the LOC/REM key and then the stop

key .

Chapter overview

This chapter describes briefly the operating principle and construction of the

converter modules in short.

The DCS800

The DCS800-S size D1 - D7 are intended for controlling DC motors

Chapter overview

This chapter describes the mechanical installation of the DCS800.

Unpacking the unit

• Open the box,

• take out shock dampers,

• separate manual and accessories.

Attention:

Do not lift the drive by the cover!

Delivery check

Check that there are no signs of damage. Before attempting installation and

operation, check the information on the nameplate of the converter module to verify

that the unit is of the correct type. The label includes an IEC rating, cULus, C-tick

(N713) and CE markings, a type code and a serial number, which allow individual

identification of each unit. The remaining digits complete the serial number so that

there are no two units with the same serial number.

See an example nameplate below.

Before installation

Install the drive in an upright position with the cooling section facing a wall. Check

the installation site according to the requirements below. Refer to chapter

Dimensions and weights for frame details.

Requirements for the installation site

See chapter Technical data for the allowed operation conditions of the drive.

Wall

The wall should be as close to vertical as possible, of non-flammable material and

strong enough to carry the weight of the unit. Check that there is nothing on the wall

to inhibit the installation.

Floor

The floor or material below the installation should be non-flammable.

Free space around the unit

Around the unit free space is required to enable cooling airflow, service and