ABB2600T Series Pressure Transmitters

2600T Series Pressure Transmitters Models 265, 267, 269

Current limitation This electronic implements also an especial circuitry for the current limitation. Whenever a fatal failure occurs and the current consumption increase over the 19 mA, this circuitry provides a limitation of the current to 19 mA, in order to save the good functionality of the other connected devices that otherwise would be switched off due to the missing power available. 3.2 Local Display The 2000T FF Pressure Transmitter is available with an integral display as optionally item, see the Figure 1. This integral display offers the possibility to display the selected variable or diagnostic strings whenever failure and/ or warnings are detected. The variable to be displayed is user selectable among several variables produced in the TB as well as the Function Blocks output in Engineering Value, or its percentage. It is selected writing the right code in the RB_METER_OPTION. See section 8.2 in the Resource Block table. – If the transmitter works correctly, the variable selected in the RB_METER_OPTION is displayed together with the unit code, and it is updated periodically. If the value is to high to show 'OVERFLOW' is displayed. – When some malfunctions are detected on the display appears the following diagnostic string sequences: 'ALARM'. The first column of the second row shows some special characters in cyclic order. This characters are the number of the shown value, write protection, transfer function, status available and EEPROM burning activ. Below the displayed value is a percent bar. The value there displayed is the OUT value of the AI1 FB at normal transmitters or the mass flow (norm volume flow) at multivariable transmitters. The display acts also as feedback of the operations performed with the external push buttons, for additional display indications see the "structure tree" Figure 3-3 on page 11.

3.3 Local Keys 3 external push buttons are available, see the Figure 2 To make the keys accessible, release the screw and turn the protection cap aside. Figure 3-2 Push Buttons View Simulation: The simulation can be activated as follows (see also symbolism on the plate). (1) First, fully press down the mode key "M" with an appropriate screw driver. 2. Then turn the switch clockwise by 90 ° angle . For deactivation the switch has to be pushed down a little and turned counterclockwise by 90 ° angle. Without display: The "-"/"+" keys have the same function like TB_SET_LOWER_RANGE and TB_SET_UPPER_RANGE. The mode ckey "M" enables/disables the simulation mode. With display: With the mode key "M", you can start menu-controlled program-ming. To call the next menu item, press the key "+". You will return via the key "- ". Submenu items / selection lists are acti-vated via the mode key "M". A numerical value can only be changed via the keys "+" and " - ". It must be taken into account that the key "+" changes the value (each keystroke increases the value by 1), whereas the position of the value to be changed is reached via the key " - ". Acknowledge changes with the mode key "M"; the subsequent OK acknowledgement (via the key "M", "+" or "-") writes the new value into the failsafe storage. An ad-justing process can be aborted by pressing simultaneously the keys "+" and "-". From any main menu item, you can return to the menu item "EXIT" by simultaneous-ly pressing the "+" and "-" keys. When the adjustment has been finished, quit the program via the menu item "EXIT". By means of the following structure tree, you will get an overview of the selection / programming possibilities.

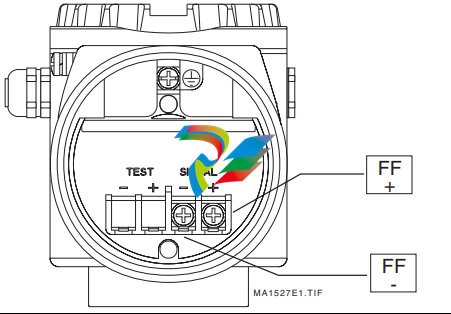

4.1 Electrical Connections The 2600 FF is a Bus Powered device with Foundation Fieldbus output. On the terminal block two screws for the BUS CONNECTION are available, see the Figure 4-4 on page 14. The Polarity has not consistency, so the two bus cables can be connected without take care about the polarity.

Device Addressing When the models 265/267/269 FF Transmitter is connected on a FF bus, the Master has to recognize it with a unique address in the world. For this reason the FF specifications define three different addressing levels that characterize the FF devices: – The DEV_ID is the unique device identifier. – The PD_TAG is the physical name of the device. – The Node Address is the real node at which the device is connected on the bus. It is automatically set by the Master (Primary LAS). The most important one with the higher priority is the DEV_ID. This is a string of 32 characters and must identify in a unique way each FF device in the world. In order to fulfill this requirement the models 265/267/269 FF applies the following mechanism: – The first part of the string is of 10 characters; the Manufacturer Code "000320" and Device Type code "0089" for 265, "008A" for 267/269. – The second part of the string is of 12 characters and represent the device type identification; "_2600T_TO___" for 265, "_2600T_MV___" for 267/269. – The third part of the string is of 10 characters and is filled with the TB_SENSOR_SERIAL_NUMBER read from the transducer database. This number is written at factory configuration stage and it is assigned in a well-defined way just to be sure to have always different numbers. Finally the DEV_ID appears of 32 characters in this way '0003200089_2600T_TO___xxxxxxxxxx', where the entire 'x' represents the Serial number. Whenever an electronics replacement after an electronics failure is necessary, appear clear that the device will be recognized on the network as before of the replacement. This is possible because the transducer, which includes the serial number, remains unchanged and the DEV_ID will be maintained the same as before of the failure.