Ndrive CP Hardware Manualvvv

Agency Approvals

Aerotech, Inc. Model Ndrive CP Series Digital Drives have been tested and found to be in accordance to the following listed Agency Approvals:

Approval / Certification: CUS NRTL Approving Agency: TUV SUD America Inc. Certificate #: U8 17 01 68995 023 Standards: CAN/CSA-C22.2 No. 61010-1:2012; UL 61010-1:2012

Visit https://www.tuev-sued.de/product-testing/certificates to view Aerotech's TÜV SÜD certificates. Type the certificate number listed above in the search bar or type "Aerotech" for a list of all Aerotech certificates.

Safety Procedures and Warnings

This manual tells you how to carefully and correctly use and operate the Ndrive CP. Read all parts of this manual before you install or operate the Ndrive CP or before you do maintenance to your system. To prevent injury to you and damage to the equipment, obey the precautions in this manual. The precautions that follow apply when you see a Danger or Warning symbol in this manual. If you do not obey these precautions, injury to you or damage to the equipment can occur. If you do not understand the information in this manual, contact Aerotech Global Technical Support.

This product has been designed for light industrial manufacturing or laboratory environments. The protection provided by the equipment could be impaired if the product is used in a manner not specified by the manufacturer.

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any time. All drawings and illustrations are for reference only and were complete and accurate as of this manual’s release. Refer to www.aerotech.com for the most up-to-date information.

D A N G E R :

: This product contains potentially lethal voltages. To reduce the possibility of electrical shock, bodily injury, or death the following precautions must be followed.

1. Disconnect electrical power before servicing equipment. 2. Disconnect electrical power before performing any wiring. 3. Access to the Ndrive CP and component parts must be restricted while connected to a power source. 4. To minimize the possibility of electrical shock and bodily injury, extreme care must be exercised when any electrical circuits are in use. Suitable precautions and protection must be provided to warn and prevent persons from making contact with live circuits. 5. Install the Ndrive CP inside a rack or enclosure. 6. The shunt resistor temperature can exceed 70°C during normal operation and contains lethal voltage on its terminals and surface. It must be properly enclosed and shielded to avoid risk of fire and operator shock. 7. Do not connect or disconnect any electrical components or connecting cables while connected to a power source. 8. All components must be properly grounded in accordance with local electrical safety requirements. 9. Operator safeguarding requirements must be addressed during final integration of the product.

D A N G E R : The Ndrive CP case temperature may exceed 70°C in some applications

W A R N I N G : To minimize the possibility of electrical shock, bodily injury or death the following precautions must be followed

1. If the product is used in a manner not specified by the manufacturer, the protection provided by the product can be impaired and result in damage, shock, injury, or death.

2. Moving parts can cause crushing or shearing injuries. Access to all stage and motor parts must be restricted while connected to a power source.

3. Cables can pose a tripping hazard. Securely mount and position all system cables to avoid potential hazards.

4. Do not expose this product to environments or conditions outside of the listed specifications. Exceeding environmental or operating specifications can cause damage to the equipment.

5. Operators must be trained before operating this equipment.

6. All service and maintenance must be performed by qualified personnel.

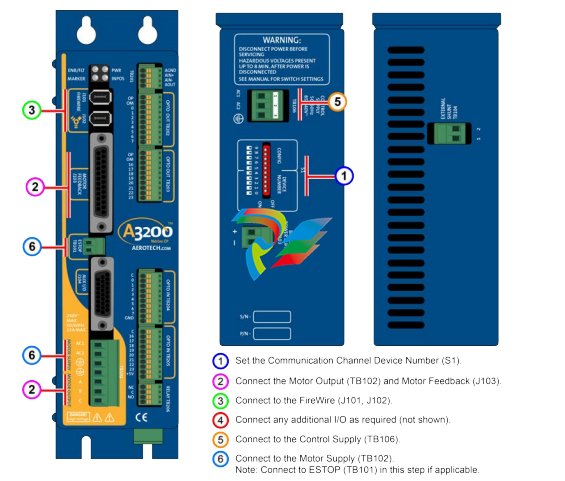

Quick Installation Guide

This chapter describes the order in which connections and settings should typically be made to the Ndrive CP. If a custom interconnection drawing was created for your system (look for a line item on your Sales Order under the heading “Integration”), that drawing can be found on your installation device.

Chapter 1: Introduction

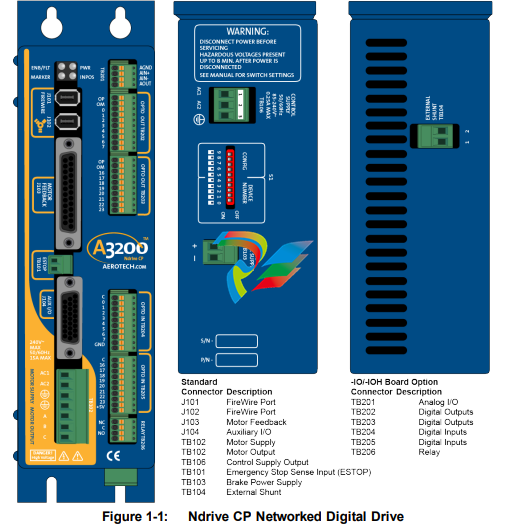

Aerotech’s Ndrive CP (Compact PWM) network digital drive is a high performance amplifier. The drive provides deterministic behavior, auto-identification, and easy software setup. The Ndrive CP’s high performance double precision floating point DSP controls the digital PID and current loops. All system configuration is done using software-settable parameters, including control loop gains and system safety functions.

The Ndrive CP is offered with an optional encoder interpolation feature (-MXU), an auxiliary square wave encoder input for dual loop control, dedicated analog and digital I/O (expandable with the -IO option), and separate power connections for motor and control supply voltages.

1.1. Drive and Software Compatibility

The following table lists the available drives and which version of the software first supported the drive. Drives that list a specific version number in the Last Software Version column will not be supported after the listed version

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)