AEROTECHNdrive HP 10/20/30 USER'S MANUAL

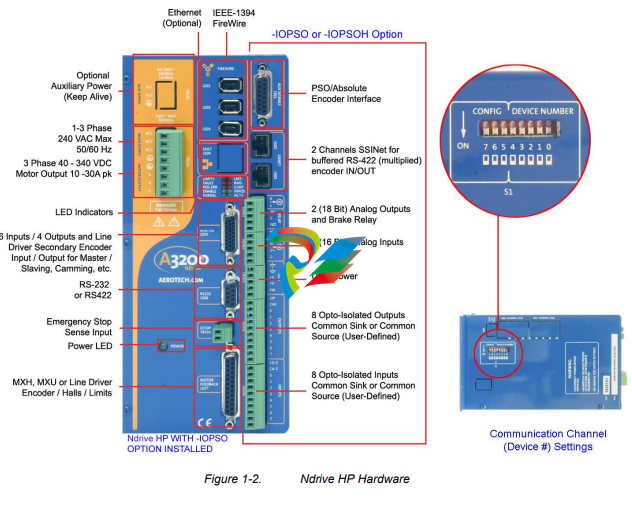

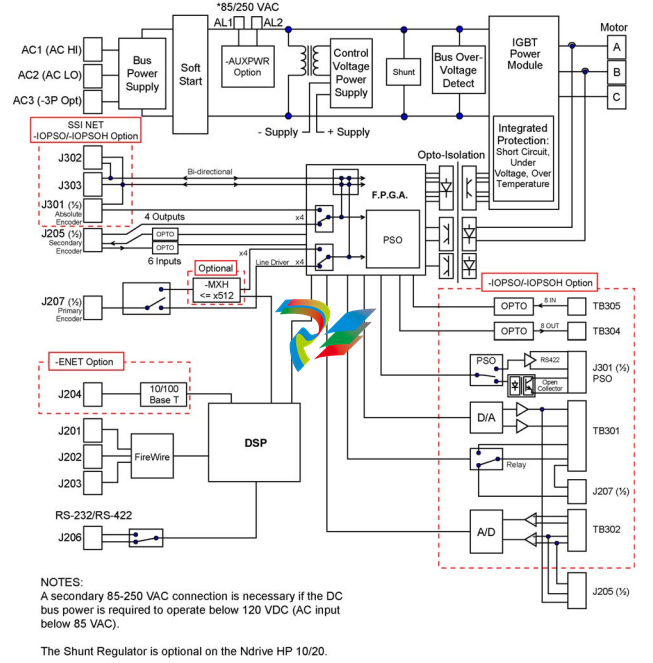

1.3. Functional Diagram

The standard package includes the bus power supply that operates from 85-250 VAC (120 ñ 350 VDC). The power supply is included with the standard package for off-line operation without the need for an isolation transformer. A soft start circuit is included to prevent high inrush currents.

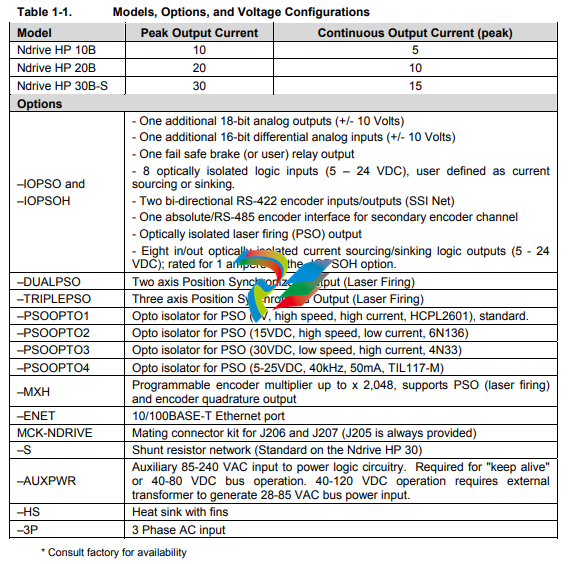

1.4. Ordering Information

The Ndrive HP is available in three models with continuous power, ranging from 1,360 to 4,080 watts. A list of these models, and the available voltage configurations, are shown in Table 1-1. See Table 1-2 for a list of available accessories.

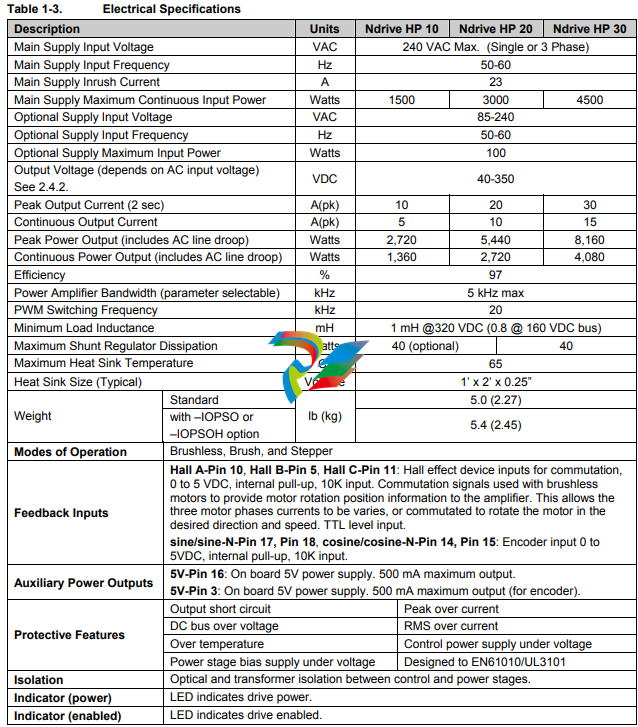

1.5. Specifications 1.5.1. Electrical Specifications

1.5.2. Mechanical Specifications The outline dimensions for the Ndrive HP are shown in Figure 1-4 and Figure 1-5. Units should be separated from each other and surrounded by one inch of free air space. This will also allow the standard 228 mm (9 inch) FireWire cable to interconnect them.

1.5.3. Environmental Specifications

The environmental specifications for the Ndrive HP are listed below.

• Temperature: Ambient Operating - 5° - 40°C (41° - 104°F) Storage - -20 - 70°C (-4 - 158°F)

• Humidity: Maximum relative humidity is 80% for temperatures up to 31°C. Decreasing linearly to 50% relative humidity at 40°C. Non-condensing.

• Altitude Up to 2000 m.

• Pollution Pollution degree 2 (normally only non-conductive pollution).

• Use Indoor use only

CHAPTER 2: INSTALLATION and CONFIGURATION

This section covers the hardware configurations using the switches, jumpers, connectors, and power connections when used with a brush, brushless, or stepper motor. Wiring, grounding, shielding techniques, and the motor phasing process are also covered. Aside from the obvious requirements of AC input and motor wiring, the only other typical requirement is to set the Ndrive HPs communication channel number via switch S2.

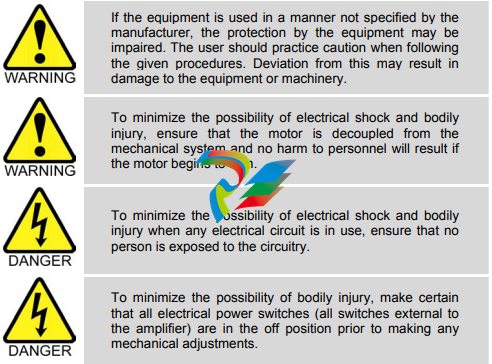

Safety Procedures and Warnings

The following statements apply wherever the Warning or Danger symbol appears within this manual. Failure to observe these precautions could result in serious injury to those performing the procedures and/or damage to the equipment.

2.2. Wiring, Grounding, and Shielding Techniques

To reduce electrical noise in the Ndrive, the user should observe the motor and input power wiring techniques explained in the following sections (suitable for use on a circuit capable of delivering not more than 5,000A, 240V).

2.2.1. Minimizing EMI Interference

The Ndrive HPs are high efficiency PWM amplifiers operating at a 20 kHz switching rate. This switching rate can generate Electromagnetic Interference (EMI) into the MHz band. To minimize this EMI, it is recommended that the motor leads be twisted together with the motor cable grounding wire and surrounded with a foil or braided shield. In addition to the EMI effects, electro-static (capacitive) coupling to the motor frame is very high, requiring the frame to be grounded in order to eliminate a shock hazard. Additional electro-static coupling exists between the three twisted motor leads and the foil shield of the motor cable. This coupling forces high frequency currents to flow through the returning earth ground of the motor cable. To minimize this problem and maintain low levels of EMI radiation, perform the following.

Use shielded cable to carry the motor current and connect the shield to earth ground.

2. Use a cable with sufficient insulation. This will reduce the capacitive coupling between the leads that, in turn, reduces the current generated in the shield wire.

3. Provide strong earth ground connections to the amplifier, additional heat sink, and the motor. Offering electrical noise a low impedance path to earth ground not only reduces radiated emissions, but also improves system performance.

4. If possible, do not route motor cables near cables carrying logic signals and use shielded cable to carry logic signals.

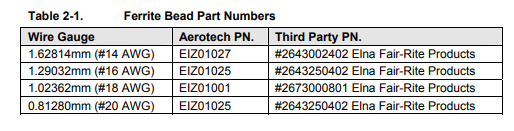

5. Ferrite beads or Aerotechís FBF-1 or FBF-2 filter adapters, may be used on the motor leads to reduce the effects of amplifier EMI/RFI, produced by PWM (pulse width modulation) amplifiers. Refer to the FBF-1 and FBF-2 drawings on your software or documentation CD ROM for more information on the ferrite beads.

2.2.2. Minimizing 50/60 HZ Line Interference

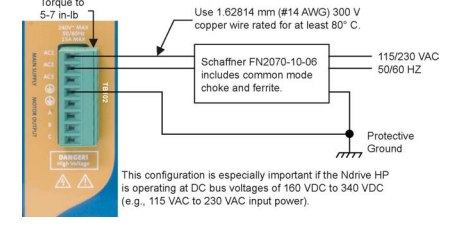

Operating the Ndrive HP from an off-line source of 115 VAC or 230 VAC may create some additional issues. There is a potential problem of EMI generated from the switching power stage of the Ndrive propagating through the bridge rectifier and out through the AC1 and AC2 input AC line connections. Back-propagation of noise into the AC lines can be minimized using a line filter (refer to Figure 2-1)

Figure 2-1. Back-Propagation Line Filter Connection

Second, a potential problem that exists with off line connections is 50/60 Hz electrostatic coupling between the frame of the AC motor and the AC1/AC2 AC input power. Since AC1 is referenced to earth ground at the source, the DC bus of the amplifier ìswingsî at 50/60 Hz with respect to the motor frame. The path of current caused by this coupling between the motor frame and the amplifier stage passes through the current feedback sensing devices of the amplifier. Depending on the magnitude of this current, a 50/60 Hz disturbance may be visible in the position error. To eliminate this problem, an isolation transformer can be used to block the 50/60 Hz from being seen by the motor frame (refer to Figure 2-2).

.png)

.png)

.png)