AEROTECHNdrive HP 10/20/30 USER'S MANUAL

General notes concerning the test setup

This product was tested at F-Squared Laboratories, in Burton, OH on April 16-18, 2002. The report numbers are NY011602-01-01E and NY011602-01-02E. The Ndrive HP was tested while powered from a 230VAC source with a brushless servomotor, connected via PMC-15 and BFC-15 (15 foot) cables. In order for the product to conform to the radiated emission standards, the motor cable must be shielded and the shield must be connected to the earth ground. A metal D-style connector with a metal backshell must be used when connecting to the D-style connectors on the Ndrive HP. The shield of the feedback cable must be connected to the metal backshell.

The following modifications ensure compliance:

• Install a snap-on Ferrishield ferrite attenuator, P/N SS28B2034, on the FireWire cable at the unit.

• Install a Curtis, P/N F1600CA-10, EMI line filter on the AC input.

• Install two snap-on Ferrishield ferrite attenuators, P/N SS28B2032 and CS28B1984, on the AC cable between the EMI line filter and the Ndrive.

• Connect earth ground to the mounting screw at the AC input.

• Install a SCI, 25-pin, D-style, Spectrum EMI filter adapter, P/N SCI-56-725-001, in series with the motor feedback cable at the unit. Current generation units (Revision A) have integral filtering built-in, which should preclude the use of this EMI filter, based upon similar product testing.

Safety related requirements to ensure compliance (exceptions to EN 61010-1):

• The Ndrive must be installed within an enclosure with construction compliant unlimited circuits.

• The end user is responsible for meeting the final protective ground requirements. • The AC power inlet located on the front of the Ndrive is the power disconnect. The end user is responsible for determining and providing a supply disconnect for the system.

• The end user is responsible for preventing unexpected startup.

• Connection requirements are described in the technical documentation provided with the product. The end user is responsible for making the proper connections and meeting any required interlock requirements for the product application.

• Voltages greater than 60V may be present inside the Ndrive after a discharge time of 5 seconds.

• The end user must provide protection for power interruption / restoration, if required.

• The end user must provide earth fault current protection, if required. • The end user must provide protection against lightning and power switching surges, if required.

• Control and Emergency Stop requirements are to be determined and provided by the end user.

• Wire and cabling provided with the Ndrive meet Aerotechís electrical and listed environmental requirements. The end user must meet the final requirements.

CHAPTER 1: INTRODUCTION

Aerotechís Network Digital Drives (Ndrive HP) complement the Automation 3200 System (see Figure 1-1). Connected via the IEEE-1394 (FireWireÆ) communication bus, these drives provide deterministic behavior, auto-identification, and easy software setup from the Nmotion SMC software controller. Featuring a high-speed Harvard architecture DSP, the drives have fully digital current and servo loops providing selectable 1-20 kHz servo loop closure, 40 MHz line driver encoder data rate, and an optional Ethernet port for access to third party networked I/O solutions. The Ndrive HP also features an optional on-board brake relay, programmable resolution multiplication up to x 65,536, with a 200 kHz maximum amplified sine wave input frequency, and up to three-axis Position Synchronized Outputs (laser firing). In addition, the use of the commercially standard FireWire communication link makes integration to the Automation 3200 network plug-n-play easy

1.1. Feature Summary

• Software configurable for brush, brushless and stepper motor operation

• Standard 100 VDC ñ 320 VDC Bus, optional 20 VDC ñ 80 VDC Bus, requires the -AUXPWR option

• Fully isolated power stage

• 5 VDC, 500 mA fused user output power for encoder and Hall effect signals, etc.

• Two mounting orientations optimized for heat transfer or minimal panel space utilization

• Full protection against the following failure modes:

Control supply under voltage

2. Continuous current overload

3. Power stage bias supply under-voltage

4. Power stage output short circuit (phase to phase and phase to ground)

5. DC bus over voltage

6. IGBT device over temperature sense

• Line driver square wave or analog sine wave quadrature encoder primary position and velocity feedback

• Line driver square wave auxiliary quadrature encoder input or output for PSO (laser firing), etc.

• 4 opto-isolated user outputs standard

• 6 opto-isolated user inputs standard, 2 of which are high speed

• 2 differential analog inputs (one standard and one available with the ñIOPSO option)

• 2 analog outputs (one standard and one available with the ñIOPSO option)

1.2. Connection Overview

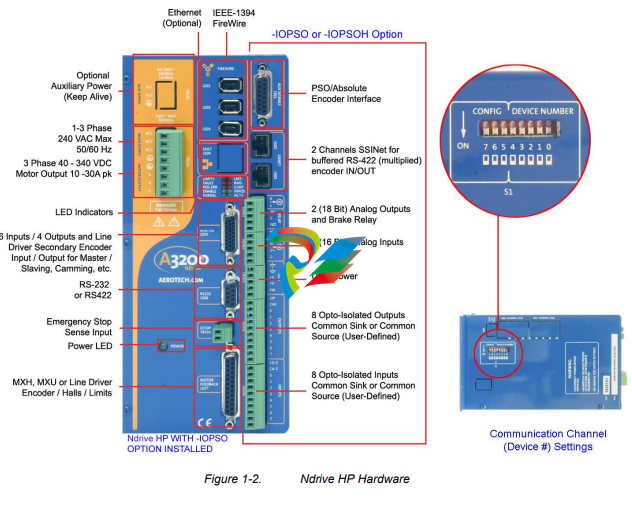

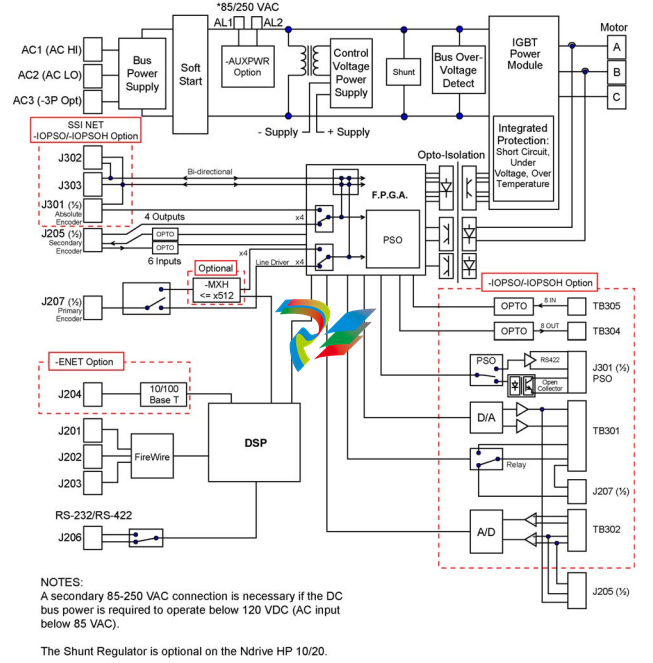

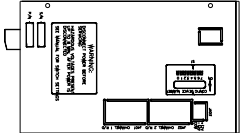

The Ndrive HP consists of two power connections (motor power and input power), three FireWire ports, an optional Ethernet connection, an RS-232/RS-422 connector, LED indicator lamps and two D-Style connectors for Auxiliary I/O (15 and 26 pin) and Motor Feedback (25 pin). An ñIOPSO or -IOPSOH option is also available, which has connectors for PSO, absolute encoder, SSI Net, analog I/O, digital I/O, and user power. Refer to Figure 1-2 for connector locations.

1.3. Functional Diagram

The standard package includes the bus power supply that operates from 85-250 VAC (120 ñ 350 VDC). The power supply is included with the standard package for off-line operation without the need for an isolation transformer. A soft start circuit is included to prevent high inrush currents.

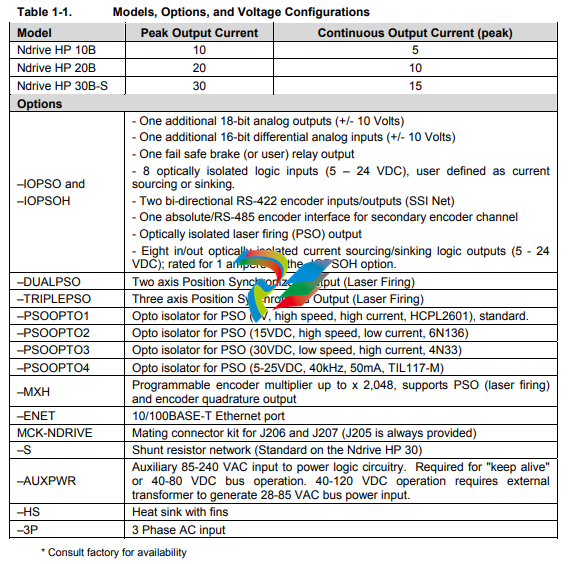

1.4. Ordering Information

The Ndrive HP is available in three models with continuous power, ranging from 1,360 to 4,080 watts. A list of these models, and the available voltage configurations, are shown in Table 1-1. See Table 1-2 for a list of available accessories.

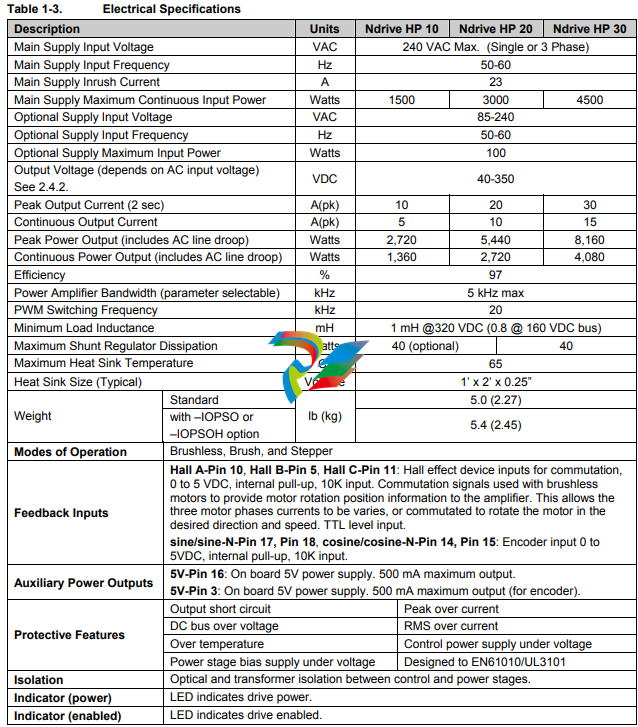

1.5. Specifications 1.5.1. Electrical Specifications

1.5.2. Mechanical Specifications The outline dimensions for the Ndrive HP are shown in Figure 1-4 and Figure 1-5. Units should be separated from each other and surrounded by one inch of free air space. This will also allow the standard 228 mm (9 inch) FireWire cable to interconnect them.

1.5.3. Environmental Specifications

The environmental specifications for the Ndrive HP are listed below.

• Temperature: Ambient Operating - 5° - 40°C (41° - 104°F) Storage - -20 - 70°C (-4 - 158°F)

• Humidity: Maximum relative humidity is 80% for temperatures up to 31°C. Decreasing linearly to 50% relative humidity at 40°C. Non-condensing.

• Altitude Up to 2000 m.

• Pollution Pollution degree 2 (normally only non-conductive pollution).

• Use Indoor use only

CHAPTER 2: INSTALLATION and CONFIGURATION

This section covers the hardware configurations using the switches, jumpers, connectors, and power connections when used with a brush, brushless, or stepper motor. Wiring, grounding, shielding techniques, and the motor phasing process are also covered. Aside from the obvious requirements of AC input and motor wiring, the only other typical requirement is to set the Ndrive HPs communication channel number via switch S2.

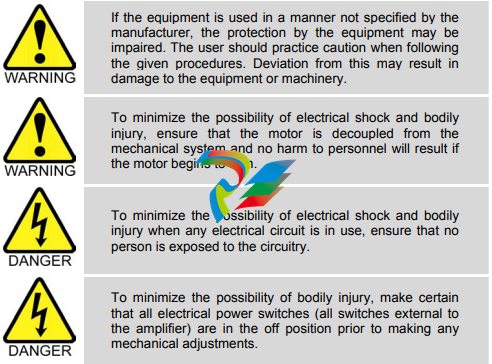

Safety Procedures and Warnings

The following statements apply wherever the Warning or Danger symbol appears within this manual. Failure to observe these precautions could result in serious injury to those performing the procedures and/or damage to the equipment.

2.2. Wiring, Grounding, and Shielding Techniques

To reduce electrical noise in the Ndrive, the user should observe the motor and input power wiring techniques explained in the following sections (suitable for use on a circuit capable of delivering not more than 5,000A, 240V).

2.2.1. Minimizing EMI Interference

The Ndrive HPs are high efficiency PWM amplifiers operating at a 20 kHz switching rate. This switching rate can generate Electromagnetic Interference (EMI) into the MHz band. To minimize this EMI, it is recommended that the motor leads be twisted together with the motor cable grounding wire and surrounded with a foil or braided shield. In addition to the EMI effects, electro-static (capacitive) coupling to the motor frame is very high, requiring the frame to be grounded in order to eliminate a shock hazard. Additional electro-static coupling exists between the three twisted motor leads and the foil shield of the motor cable. This coupling forces high frequency currents to flow through the returning earth ground of the motor cable. To minimize this problem and maintain low levels of EMI radiation, perform the following.

Use shielded cable to carry the motor current and connect the shield to earth ground.

2. Use a cable with sufficient insulation. This will reduce the capacitive coupling between the leads that, in turn, reduces the current generated in the shield wire.

3. Provide strong earth ground connections to the amplifier, additional heat sink, and the motor. Offering electrical noise a low impedance path to earth ground not only reduces radiated emissions, but also improves system performance.

4. If possible, do not route motor cables near cables carrying logic signals and use shielded cable to carry logic signals.

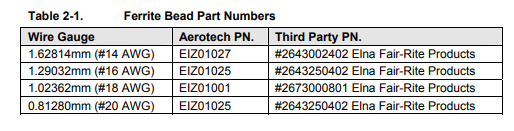

5. Ferrite beads or Aerotechís FBF-1 or FBF-2 filter adapters, may be used on the motor leads to reduce the effects of amplifier EMI/RFI, produced by PWM (pulse width modulation) amplifiers. Refer to the FBF-1 and FBF-2 drawings on your software or documentation CD ROM for more information on the ferrite beads.

2.2.2. Minimizing 50/60 HZ Line Interference

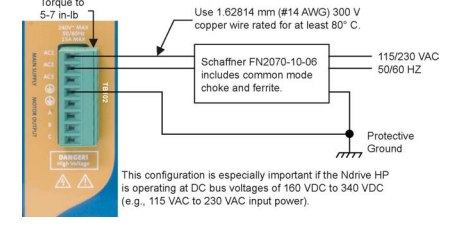

Operating the Ndrive HP from an off-line source of 115 VAC or 230 VAC may create some additional issues. There is a potential problem of EMI generated from the switching power stage of the Ndrive propagating through the bridge rectifier and out through the AC1 and AC2 input AC line connections. Back-propagation of noise into the AC lines can be minimized using a line filter (refer to Figure 2-1)

Figure 2-1. Back-Propagation Line Filter Connection

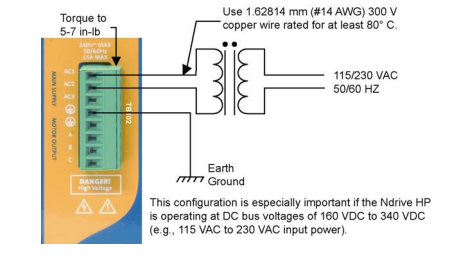

Second, a potential problem that exists with off line connections is 50/60 Hz electrostatic coupling between the frame of the AC motor and the AC1/AC2 AC input power. Since AC1 is referenced to earth ground at the source, the DC bus of the amplifier ìswingsî at 50/60 Hz with respect to the motor frame. The path of current caused by this coupling between the motor frame and the amplifier stage passes through the current feedback sensing devices of the amplifier. Depending on the magnitude of this current, a 50/60 Hz disturbance may be visible in the position error. To eliminate this problem, an isolation transformer can be used to block the 50/60 Hz from being seen by the motor frame (refer to Figure 2-2).

2.3. Power Connections

The Ndrive HP may powered by one or two separate AC voltages. One for motor bus power and optionally a second for control power, as described in the following two subsections. If the optional control power input is present, it must be powered.

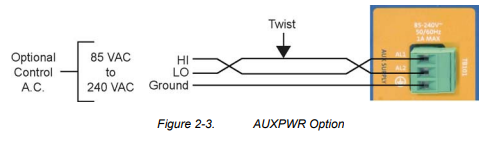

2.3.1. Control Power Connections (TB101)

The -AUXPWR option allows the Ndrive HP to remain operational when the motor power is removed, such as when an external emergency stop circuit is required. If the Ndrive HP was purchased with the -AUXPWR option, a separate AC input (TB101) has been included on the amplifier. The internal power supply of the Ndrive HP requires a minimum of 85 VAC input to operate properly. The figure below shows the connection to the separate AC power board. The connection is made to the AC input board with a three terminal connector (Aerotech Part #ECK00213), provided. See Section 2.4. for various typical AC wiring options. TB101 is also typically utilized when an emergency stop circuit is present. See Section 2.10 for a typical ESTOP sense input wiring configuration.

The AUXPWR input is an option that, if present, must be powered. It is typically used when the AC bus input power is less than 85 VAC at TB102 AC1, AC2 (or AC3). TB101 is also typically utilized when an emergency stop circuit is present. Optional Supply Connections to AL1, AL2 and the Protective Ground should be at least 1.02362 mm (#18 AWG) wire rated @ 300 V (3 Amp external fusing may be required for AL2, AL1 is fused internally at 3 Amps).

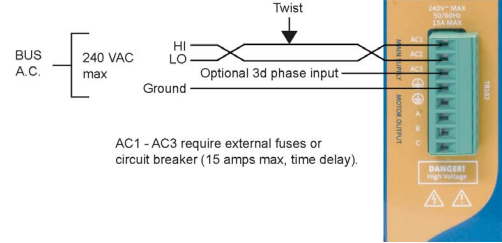

2.3.2. Motor Power Connections (TB102)

The three-phase motor terminal connections are made at connections A, B, and C. Motor Connections ØA, ØB, ØC and its Protective Ground should be made with 1.62814 mm (#14 AWG) wire rated at 300 V. Motor frame and shield connect to (ground). Input power to the Ndrive is made at the AC1 and AC2 terminals with earth ground connected to (ground). A three-phase power input is also available (AC3, requires 3 Phase Option). Connections at AC1, AC2 and AC3 and its Protective Ground should be made with 1.62814 mm (#14 AWG) wire rated at 300V

2.3.3. 40/80 VDC Power Transformers The TV0.3-56 power transformer is an optional accessory for the Ndrive HP. The transformer allows the generation of 56 VAC from a 115 VAC and 230 VAC source respectively. When rectified by the Ndrive HP, 56 VAC yields an 80 VDC power bus. The TV0.3-28 power transformer is an optional accessory available for the Ndrive HP. This transformer allows for the generation of 28 VAC from a 115 VAC or 230 VAC source, respectively. When rectified by the Ndrive, 28 VAC yields a 40 VDC power bus. The following three figures illustrate the six combinations available for both AC input voltages and all three DC bus voltages, as well as the use of the -AUXPWR option. A TM3 and TM5 transformer package is also available to power up to four Ndrives, providing 300 or 500 watts of power.

APPENDIX B: WARRANTY and FIELD SERVICE

Aerotech, Inc. warrants its products to be free from defects caused by faulty materials or poor workmanship for a minimum period of one year from date of shipment from Aerotech. Aerotech's liability is limited to replacing, repairing or issuing credit, at its option, for any products that are returned by the original purchaser during the warranty period. Aerotech makes no warranty that its products are fit for the use or purpose to which they may be put by the buyer, where or not such use or purpose has been disclosed to Aerotech in specifications or drawings previously or subsequently provided, or whether or not Aerotech's products are specifically designed and/or manufactured for buyer's use or purpose. Aerotech's liability or any claim for loss or damage arising out of the sale, resale or use of any of its products shall in no event exceed the selling price of the unit. Aerotech, Inc. warrants its laser products to the original purchaser for a minimum period of one year from date of shipment. This warranty covers defects in workmanship and material and is voided for all laser power supplies, plasma tubes and laser systems subject to electrical or physical abuse, tampering (such as opening the housing or removal of the serial tag) or improper operation as determined by Aerotech. This warranty is also voided for failure to comply with Aerotech's return procedures. Laser Products Claims for shipment damage (evident or concealed) must be filed with the carrier by the buyer. Aerotech must be notified within (30) days of shipment of incorrect materials. No product may be returned, whether in warranty or out of warranty, without first obtaining approval from Aerotech. No credit will be given nor repairs made for products returned without such approval. Any returned product(s) must be accompanied by a return authorization number. The return authorization number may be obtained by calling an Aerotech service center. Products must be returned, prepaid, to an Aerotech service center (no C.O.D. or Collect Freight accepted). The status of any product returned later than (30) days after the issuance of a return authorization number will be subject to review. Return Procedure After Aerotech's examination, warranty or out-of-warranty status will be determined. If upon Aerotech's examination a warranted defect exists, then the product(s) will be repaired at no charge and shipped, prepaid, back to the buyer. If the buyer desires an airfreight return, the product(s) will be shipped collect. Warranty repairs do not extend the original warranty period. Returned Product Warranty Determination After Aerotech's examination, the buyer shall be notified of the repair cost. At such time, the buyer must issue a valid purchase order to cover the cost of the repair and freight, or authorize the product(s) to be shipped back as is, at the buyer's expense. Failure to obtain a purchase order number or approval within (30) days of notification will result in the product(s) being returned as is, at the buyer's expense. Repair work is warranted for (90) days from date of shipment. Replacement components are warranted for one year from date of shipment. Returned Product Non-warranty Determination At times, the buyer may desire to expedite a repair. Regardless of warranty or out-ofwarranty status, the buyer must issue a valid purchase order to cover the added rush service cost. Rush service is subject to Aerotech's approval.

On-site Warranty Repair

If an Aerotech product cannot be made functional by telephone assistance or by sending and having the customer install replacement parts, and cannot be returned to the Aerotech service center for repair, and if Aerotech determines the problem could be warranty-related, then the following policy applies: Aerotech will provide an on-site field service representative in a reasonable amount of time, provided that the customer issues a valid purchase order to Aerotech covering all transportation and subsistence costs. For warranty field repairs, the customer will not be charged for the cost of labor and material. If service is rendered at times other than normal work periods, then special service rates apply. If during the on-site repair it is determined the problem is not warranty related, then the terms and conditions stated in the following "On-Site Non-Warranty Repair" section apply.

On-site Nonwarranty Repair

If any Aerotech product cannot be made functional by telephone assistance or purchased replacement parts, and cannot be returned to the Aerotech service center for repair, then the following field service policy applies: Aerotech will provide an on-site field service representative in a reasonable amount of time, provided that the customer issues a valid purchase order to Aerotech covering all transportation and subsistence costs and the prevailing labor cost, including travel time, necessary to complete the repair.

.png)

.png)

.png)