DOOSANDOOSAN AC SERVO MOTOR/DRIVE VISION DVSC - TM Series

Installation and wiring

1.1. Designations

Designations of DOOSAN AC Servo Motor and Drive are as follows.

Please refer to this section for system installation and after service.

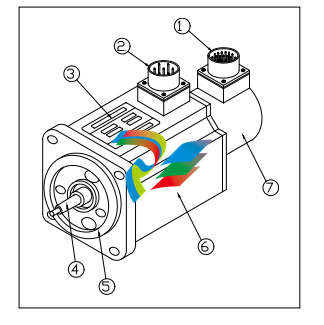

1)Encoder Connector 2)Power Connector 3)Name Plate 4)Shaft 5 )Flange 6 )Frame 7 )Encoder

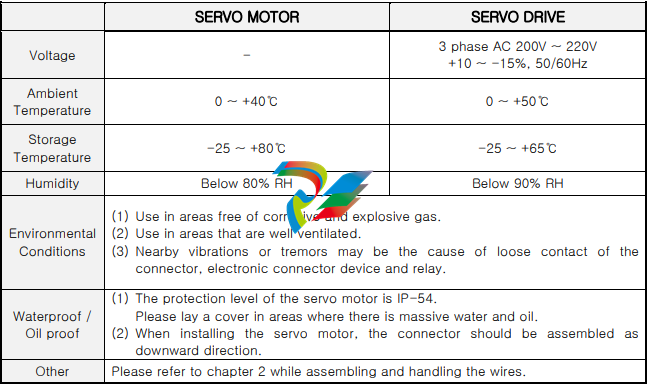

1.2. Environmental conditions

This product was designed for indoor usage.

Caution : If used in different circumstances and environment other than stated below, damages

may occur.

Please use under the following conditions.

1.3. Installation method

1.3.1. Assembling of the servo motor

▷ Warning: While assembling the servo motor, avoid dropping it.

▷ Caution: While mounting the servo motor horizontally, the connector should be assembled

facing downward.

▷ The servo motor can be mounted horizontally or vertically.

▷ To prevent vibrations and extend the life of coupling and bearing, the motor shaft and the loading

shaft should be precisely aligned. Use flexible coupling when connecting directly to the load.

① The outer part of the coupling should be measured at four equidistant points each 90˚ apart,

and the gap between the maximum and the minimum readings should not exceed 0.03㎜.

② The center point of the motor and the loading shaft should be precisely aligned.

▷ Avoid excessive radial and thrust load to the motor shaft and also avoid impact that is more

than 10G when mounting the gear, coupling, pulley and etc. at the same time.

▷ A minus load means continuous operation in the regenerative braking state, when the motor is

rotated by load. The regenerative braking capacity of the servo drive is short term rated

specification equivalent to stop time of the motor. Thus, it should not be used in minus load that

generates continuous regenerative braking.

ex) Servo system for descending objects(without counterweight)

▷ The admissible load inertia into the motor shaft is within 5 times than the inertia of applied servo

motor. If it exceeds this, during deceleration it may cause regenerative malfunction.

The following steps should be taken if the load inertia exceeds more than 5 times the inertia of

the servo motor.

- Reduce the current limit. – Decelerate slowly.(Slow Down)

- Lower the maximum speed in use.

1.3.2. Mounting of the servo drive

▷ Warning: To prevent electric shock, turn off the power while mounting or uninstalling.

▷ While installing the panel, the size of the panel, cooling and wiring should be considered in

order to maintain a difference of temperature below 5℃ between the panel temperature and the

surrounding temperature in accordance with heat value of the equipment and box size.

▷ If a heating element is placed nearby, the surrounding temperature of the servo drive should be

maintained below 55℃ at all cases despite temperature rise by convection and radiation. Use a

fan to ventilate sealed inner air, and proper ventilation should be used for convection of the air.

▷ If a vibrating element is placed nearby, the drive should be mounted on shock absorbing surface.

▷ If the servo drive be exposed to corrosive gas for a long time, may cause damages to connecting

devices such as relay and circuit breaker, thus it should be avoided.

▷ Environmental conditions such as high temperature, high humidity, excessive dust and metal

particles should be avoided.

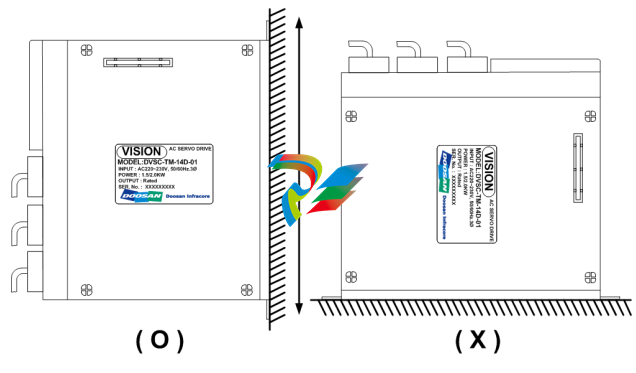

◆ Mounting method

▷ There should be a space wider than 100㎜ below and above the servo drive.

▷ There should be a space wider than 30㎜ on both sides of the servo drive.

▷ Mount the servo drive vertically. Do not use if it is mounted horizontally.

1.4. Wiring

▶ For signal lines and encoder lines, use twisted lines or multi-core shielded twisted-pair lines.

The length for command input lines should be maximum 3m, and the encoder line should be

maximum 10m or less.

Wiring must be done in shortest distance and the remaining length should be cut.

▶ The ground circuit should be a thick line. Usage of third-class grounding or above (ground

resistance 100Ω or less) is recommended. Also, make sure to ground at one-point grounding.

▶ The following precautions should be taken to avoid malfunction due to noise.

- The noise filter should be placed as near as possible.

- Mount a surge absorber to the coil of the relay, electromagnetic contacts, solenoids and etc.

- The power line (AC input, motor input line) and the signal line should be placed 30㎝ apart

or more. Do not put them into the same duct or tie them in a bundle.

- If the power source of the servo drive is used in common with an electric welder or electrical

discharge machine, or a high-frequency noise source is present, attach noise filter to the

power or the input circuits.

- Since the core wire of the signal line cable is as thin as only 0.2 ~ 0.3㎟, excessive force to the

line should be avoided to prevent damages.

1.5. Noise treatment

For wiring and grounding of the servo drive, the effect of switching noise which is generated by the

built-in IPM should be reduced as much as possible. Unexpected effect by outside noise should be

reduced as much as possible.

▶ Grounding method

The servo drive supplies power to the motor according to the switching of the IPM device.

Thus the Cf dv/dt current flows from the power component to the floating capacity of the motor.

To prevent the effect of the switching noise, the motor frame terminal should be connected to

the PE terminal of the servo drive terminal block and the PE terminal of the servo drive should be

directly grounded to standard ground panel.

▶ Noise filter

Noise filter is used in order to prevent noise from the power line. Please refer to the following

conditions while installing.

(a) Separate the input and output wiring and do not tie them together or put them into the same

duct.

(b) Do not put the ground wire into the same duct with the filter output line or other signal lines.

And do not tie them together.

(c) The ground wire should be wired singly to the ground panel.

(d) If the unit contains the filter, connect the filter and the equipment ground to the base of the

unit.

2. Operation

2.1. Automatic operation

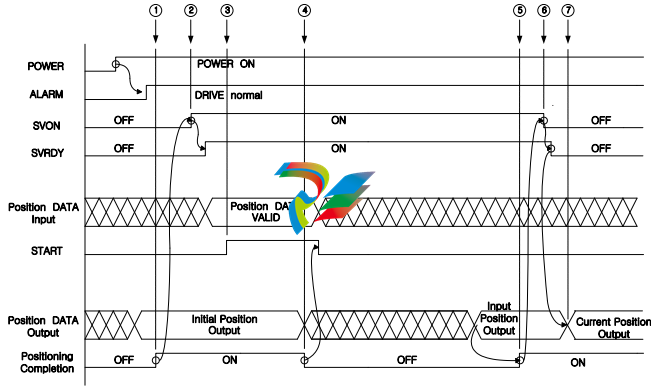

① If the drive maintains a normal state (takes 5 sec) after the POWER turns on, it outputs the initial

position data and the positioning completion signal(VPF) after it detects the initial position by the

absolute encoder.

② When the SVON signal is ON, the SVRDY signal turns ON after the inner GATE turns ON.

③ When the START signal is ON, the servo motor will rotate according to the position data.

(Maintain ON state of the START signal for about 100 ~ 200 msec.)

④ When the position movement starts, the position data 0 will be outputted with turning OFF the

VPF(Positioning Completion) signal.

⑤ When the position movement is complete, the VPF signal turns ON after the position input data is

outputted.

⑥ The host controller must turn OFF the SVON signal only after the VPF signal turns ON.

(Move to the next position after the SVRDY signal turns OFF.)

⑦ After the SVRDY and the SVON signals are turned OFF, the current position data is outputted.

2.2. Jog operation and Usage of BRAKE Signal(Magazine Port move by the jog signal)

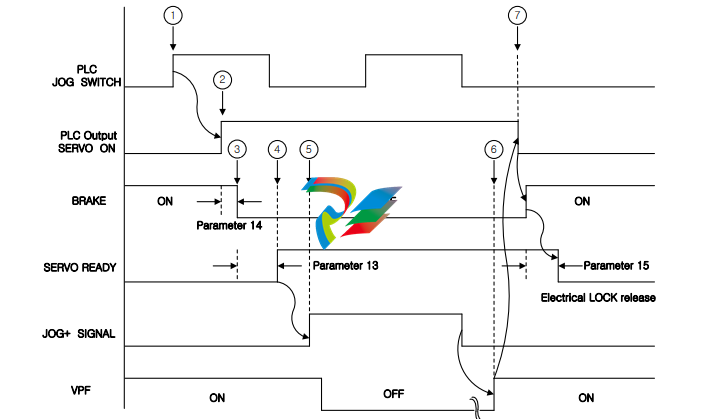

① Turn ON the Jog Switch.

② The PLC outputs the SERVO ON signal to the servo drive.

③ When the SERVO ON signal turns ON, the BRAKE release signal is outputted after the time value in

the parameter 14.

④ After the time value in the parameter 13, the SERVO READY signal is outputted.

⑤ After the SERVO READY signal is outputted, the PLC must input the JOG+ signal to the servo drive.

⑥ When the position movement is complete, the positioning completion signal(VPF) turns ON after

the position data that is increased by more than one from the previous position is outputted.

⑦ When the positioning completion signal(VPF) turns ON, the PLC turns OFF the SERVO ON signal.

Then, the servo drive turns ON the BRAKE signal and turns OFF the SERVO READY signal after the

time value in the parameter 15.

The servo drive outputs the current position data after the SERVO ON signal turns OFF.

※ In the jog mode, the motor cannot rotate over 4,000 revolutions continuously. If there is an input

over 4,000 revolutions, the motor will stop and it will not rotate. In this case, turn off the JOG+ or

JOG- signal and then turn it on again.

2.3. Parameter and Machine Origin setting method after replacement of the servo drive

At the time of the first machine assembly, it should be set the absolute encoder zero-point to the

Machine Origin. The setting method is as follows.

(These steps should be done when the external SERVO ON signal is OFF.)

2.3.1. Parameter and Machine Origin setting method of Turret/Magazine

1) Turn on the drive power.

2) Clamp the Turret.

3) Set value of the parameter 45, servo drive function selection parameter, as 0.

Please change the parameter 45 as 1 only when it needs to set as ATC because default value is 0,

Turret/Magazine. Turn the drive power OFF and then turn ON again after setting the value.

4) Initialize the parameter value.

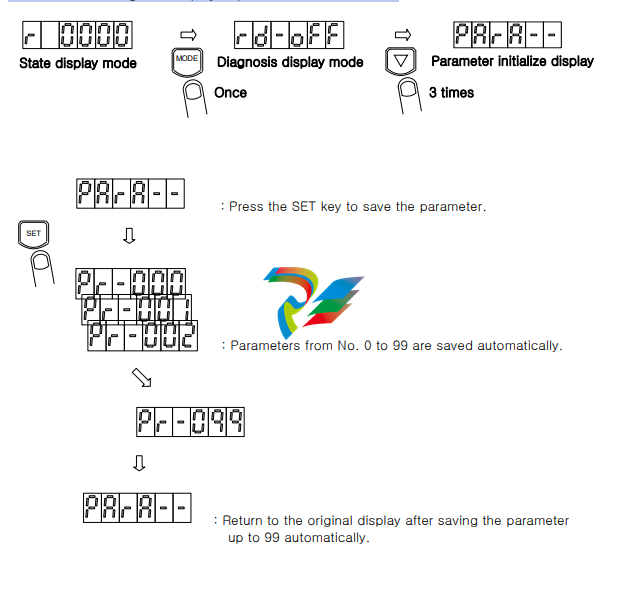

Press the MODE key to change the display to diagnosis mode, and then press the DOWN key

three times to change the display to parameter initialize mode.

Even if an alarm occurs, it’s possible to change the display as state display mode, diagnosis display

mode, parameter setting mode, origin setting mode and alarm history display mode since version

DVSC-TM-14D-02. Also, even at alarm state, parameter or offset value setting is possible since that

version.

▶ Method of releasing the alarm state

: Once the cause of the alarm is resolved, it is possible to operate the drive by turning the power

OFF and ON again.

▶ Detection time of over load

: The operation time of the over load alarm detect circuit is as listed below.

300% ~ ; 5.5sec

275% ~ ; 6.5sec

225% ~ ; 8sec

200% ~ ; 10sec

170% ~ ; 14sec

150% ~ ; 17.5sec

140% ~ ; 20sec

130% ~ ; 25sec

120% ~ ; 30sec

3.6.3. Detailed explanation of user parameter

□0 Motor output capacity

As selection parameter of the applied motor capacity, it’s possible to select 0.8, 1.5, 1.7, 2.0, 2.3,

3.0 and 4.0kW.

0 : 1.5kW 8 : 0.8kW 17 : 1.7kW 20 : 2.0kW 23 : 2.3kW 30 : 3.0kW 40 : 4.0kW

※ Use 14A drive for motors under 3.0kW and 28A drive for motors more than 3.0kW. If not applied

properly, it may cause malfunction of the motor.

□1 Motor rotation direction

This parameter sets the rotation direction of the motor. Please select according to the structure

of the equipment.

0 : Selects when the rotation direction of the motor and the equipment is the same.

1 : Selects when the rotation direction of the motor and the equipment is different.

□2 Option function

This parameter is used when the NC uses the drive itself JOG mode or sets the origin position.

For use this function, OVR0 and OVR1 contact points must be connected between the drive and

the NC, and the NC program should support this feature.

0 : Option disable 1 : Option enable

OVR0 OVR1 function

OFF ON The operation mode will be changed as the drive itself JOG, and the motor

rotates by JOG+, JOG- signals.

ON ON Machine origin setting will be executed.

□3 Direction fixing, JOG function selection

This parameter defines the function of JOG+(no.20) and JOG-(no.23) signals of CN1 connector.

0 : Defined as direction fixing signal.

JOG+ JOG- Rotation direction

OFF OFF Detects the shortest distance and rotates.

OFF ON The motor always rotates in clockwise.

ON OFF The motor always rotates in counterclockwise.

ON ON The motor always rotates in counterclockwise.

* The above statement is applicable if the parameter 1 is set as 0. If the parameter is set as

1, the motor rotates the opposite way.

1 : Magazine JOG operation signal (This is used when it need to move the tool post by the

JOG signal at the Magazine.)

JOG+ JOG- Contents

OFF OFF Only operates by position data input.

OFF ON Step JOG operates towards the direction the POST number decreases.

ON OFF Step JOG operates towards the direction the POST number increases.

ON ON Cannot be defined.

* The above statement is applicable if the parameter 1 is set as 0. If the parameter is set as

1, the motor rotates the opposite way. And, the position data input will be ignored if JOG+

and JOG- signals are ON.

※ For more detailed explanation, refer to ‘JOG operation’ section.

□4 Encoder pulse per 1 rotation

This parameter displays 1/4 value of encoder pulse count per rotation.

□5 Maximum POST number

This parameter sets the maximum POST number. If parameter 46 is set as 3, it’s possible to set as

maximum 255. At the Teaching mode, it’s available up to 99. The position data input exceeding the

setting number will be ignored.

Setting range : 2 ~ 127 or 255 Teaching function : 2 ~ 99

□6 Gear ratio of motor side

This parameter sets the motor rotation counts until the machine moves up to the POST set in the

parameter 7.

Setting range : 1 ~ 9999

□7 Gear ratio of machine side

This parameter sets the POST number variation until the motor rotates up to the setting data in

the parameter 6.

Setting range : 1 ~ 9999

Example)

1. At the TC model, the turret has 10 POST(10 angle) and makes 1 revolutions until the motor

makes 30.75 revolutions. In case the reduction gear ratio is determined like this, the parameter

will be set as follow, because 1 revolution of turret corresponds with 10 POST move.

Maximum POST number : 10

Gear ratio of motor side : 3075

Gear ratio of machine side : 1000

2. At the MC model, the Magazine has 41 POST(41 POT) and moves 9 POSTs until the motor

makes 101 revolutions. In case the reduction gear ratio is determined like this, the parameter will

be set as follows.

Maximum POST number : 41

Gear ratio of motor side : 101

Gear ratio of machine side : 9

□8 POST number of origin

When setting the origin of machine, input the POST number that will be set as origin into this

parameter. If parameter 46 is set as 3, it’s possible to set as maximum 255.

Please refer to ‘Machine origin setting’ for more detailed explanation.

Setting range : 1 ~ 127 or 255

□9 24 angle alternate angle function selection

This parameter sets the 24 angle alternate angle function of the Turret.

0 : Alternate angle function disable

1 : Alternate angle function enable

10 Position loop proportional gain

The proportional gain of the position loop is the parameter which determines the response of

position control loop. If the value increases, the mechanical response gets better. However,

mechanical impact on the machine may occur when the motor starts or stops. If the value

decreases, the mechanical response will get worse and position error increases by remaining pulse.

This also relates with the speed loop gain.

Setting range : 0 ~ 9999

□11 Speed loop proportional gain

The proportional gain of speed loop is the parameter which determines the response of the speed

control loop. As external characteristics, it determines the degree of rigidity. If the value of the

proportional gain increases, the rigidity becomes better. Thus the larger the setting value is the

better, but too large setting may cause oscillations and hunting. The value should be set as large

as possible under a stable condition.

Setting range : 0 ~ 9999

□12 Speed loop integral gain

The integral gain of the speed loop is a compensatory factor which reduces normal state error and

increases rigidity. If the value of integral gain is increased, the rigidity will get better. But too large

setting may cause oscillations and the system may become unstable.

Setting range : 0 ~ 9999

□13 SERVO READY ON delay time

This parameter sets the Servo Ready signal delay time to change as ON.

Setting range : 0 ~ 1000 [x 10msec]

□14 Brake OFF control delay time

In case the motor has an inner brake, this parameter sets brake release delay time.

Setting range : 0 ~ 1000 [x 10msec]

□15 Brake ON delay time

In case the motor has an inner brake, this parameter sets the time it takes for braking.

Set the value higher than actual time it takes for braking.

Setting range : 0 ~ 1000 [x 10msec]

□16 ~ □17 Reserved

□18 Positioning complete range

At position control, this parameter sets the positioning completion range. If the deviation between

the targeted position and the current position is within the setting range, the VPF terminal (no. 16

of the CN1 connector) will be turned ON. The numerical value unit means the encoder pulse and it

is 8192 pulse per rotation of the motor.

19 Remaining pulse allowable range

In position control, in each position control loop the difference between position command

and position feedback is accumulated. If this difference value exceeds the setting value, the

position deviation excess alarm will be occurred. The numerical value unit means the encoder

pulse and presently it is 8192 pulse per 1 rotation.

Setting range : 1 ~ 6000 [x 100pulse]

□20 Deceleration time after stop signal

This parameter sets the deceleration time from rotation state until the motor stops. When the

setting value is 0 as default, the motor under 3kW capacity will be stopped as 100 msec

deceleration time. And the motor more than 3kW will be stopped as 340 msec.

Setting range : 0 ~ 5000 [msec]

□21 S-shaped acceleration/deceleration time constant

This parameter sets the time constant to reduce the impact at the time of acceleration or

deceleration.

Total acceleration time : acceleration time(parameter 29) + S-shaped acceleration/deceleration

time constant

Total deceleration time : deceleration time(parameter 30) + S-shaped acceleration/deceleration

time constant

Setting range : 0 ~ 400 [msec]

□22 Positive torque limit 1

This parameter limits the torque output of the positive (+) polarity in areas except of positioning

complete range. If the value is set at 0%, positive torque will not occur. If the value is set too low,

hunting may occur when the motor starts or stops.

Setting range : 0 ~ 300 [%]

□23 Negative torque limit 1

This parameter limits the torque output of the negative (-) polarity in areas except of positioning

complete range. If the value is set at 0%, negative torque will not occur. If the value is set too low,

hunting may occur when the motor starts or stops.

Setting range : 0 ~ 300 [%]

□24 Positive torque limit 2

This parameter limits the torque output of the positive (+) polarity in areas within positioning

complete range. In purpose of applying continuous load with ON state of SVON signal after

positioning completion, the overstrain on the equipment or the motor can be avoided by setting a

low value.

25 Negative torque limit 2

This parameter limits the torque output of the negative (-) polarity in areas within positioning

complete range. In purpose of applying continuous load with ON state of SVON signal after

positioning completion, the overstrain on the equipment or the motor can be avoided by setting a

low value.

Setting range : 0 ~ 300 [%]

□26 Speed limit

This parameter limits the maximum rotation speed. Even when overshooting and such cases occur

while accelerating, the rotation speed will be limited within the setting value. Set the value at least

50rpm more than the setting value of parameter 28(rotation speed).

Setting range : 0 ~ 3000 [rpm]

□27 Jog speed at origin setting

This parameter sets the motor speed of the internal jog operation.(At Magazine, the speed of the

jog operation will be applied as the setting speed of parameter 28.)

Setting range : 1 ~ 3000 [rpm]

□28 Operation speed

This parameter sets the motor rotation speed for automatic operation or jog operation speed of the

Magazine.

Setting range : 10 ~ 3000 [rpm]

□29 Acceleration time

This parameter sets the time that takes to get to the setting speed of parameter 28 from 0 speed.

If the value is set too low, speed overshooting may occur when accelerating.

Setting range : 0 ~ 9999 [msec]

□30 Deceleration time

This parameter sets the time that takes to get to 0 speed from the setting speed of parameter 28.

If the value is set too low, positioning completion time may be delayed due to hunting when the

motor stops.

Setting range : 0 ~ 9999 [msec]

□31 Teaching function

To use the Teaching function, set this parameter as 1. It’s possible to set the movement distance

unequally unlike existing gear ratio setting method.

3000 : gear ratio setting method

1 : Teaching function enabled

□32 High torque IPM motor selection

If the high torque IPM motor is applied, set the value of this parameter as 1.

1500 : Normal SPM motor

1 : High torque IPM motor

□33 Initial state display

This parameter sets the initial display mode just after the power is ON.

Set value Initial display contents Set value Initial display contents

00 Motor rotation speed 06 Accumulated value of remaining pulse

01 Current POST number 07 Reserved

02 Absolute encoder rotation count 08 Reserved

03 Absolute encoder-one rotation 09 Alarm display

04 Effective load factor 10 Motor rotation speed

05 Maximum load factor

□34 ~ □44 Automatic setting parameters or maker parameters for management

These parameters are maker parameters for management or will be set automatically while setting

the machine origin-point.

Please do not set according to the user’s purpose. It may cause malfunction of the servo drive.

□45 Servo drive function selection

Please set this parameter first before parameter initialization or parameter setting, because this

parameter sets the servo drive function as Turret/Magazine or ATC.

Set value Function

0 Turret/Magazine

1 ATC

※ For normal operation of the servo drive, the drive power must be turned OFF and ON again,

after setting parameter 45.

□46 Option function

This parameter sets up OVERRIDE, selective application of offset and 255 TOOL function.

For use the OVERRIDE function OVR0, OVR1, OVR2 and OVR3 contact points must be connected

between the drive and the NC, and the NC program should support this feature.

For use the function of selective application of offset value, OVR0 and AUX_OUT0 contact points

must be connected between the drive and the NC, and the NC program should support this feature.

For use of 255 TOOL function, OVR0 and AUX_OUT0 contact points must be connected between

the drive and the NC, and the NC program should support this feature.

0 : Option function disabled

1 : OVERRIDE function enabled

2 : Selective application of offset value

3 : 255 TOOL function enabled

51 Tool number decrease direction Backlash

This parameter sets the Backlash compensation value for tool number decrease direction. If this

parameter is set as 0, Backlash compensation value is not applied. The numerical value unit means

the encoder pulse and presently it is 8192 pulse per 1 rotation.

Please refer to ‘Example of tool number increase direction Backlash compensation value setting’

for more detailed setting method.

Setting range : 0 ~ 9999[PULSE]

□52 Speed Command Filter

This parameter sets Speed Command Filter value. If this parameter is set as 0, Speed Command

Filter value is not applied.

Setting range : 0 ~ 9999[Hz]

□53 Speed Feedback Filter

This parameter sets Speed Feedback Filter value. If this parameter is set as 0, Speed Feedback

Filter value is not applied.

Setting range : 0 ~ 9999[Hz]

□54 Current Command Filter

This parameter sets Current Command Filter value. If this parameter is set as 0, Current Command

Filter value is not applied.

Setting range : 0 ~ 9999[Hz]

□55 Current Feedback Filter

This parameter sets Current Feedback Filter value. If this parameter is set as 0, Current Feedback

Filter value is not applied.

Setting range : 0 ~ 9999[Hz]

□56 Position Signal Output Function

Set this parameter as 1 to use position signal output function. Use this function when it needs to

output the position signal using the existing tool number output contact point at the specific

position(angle) that is set by user. And this function is available only if the NC is ready for this

feature.

0 : disabled

1 : Position signal output function enabled

.png)

.png)

.png)