ABBAC 800M PROFIBUS DP Configuration

the project. The conversion is done with the GSD Import Tool.

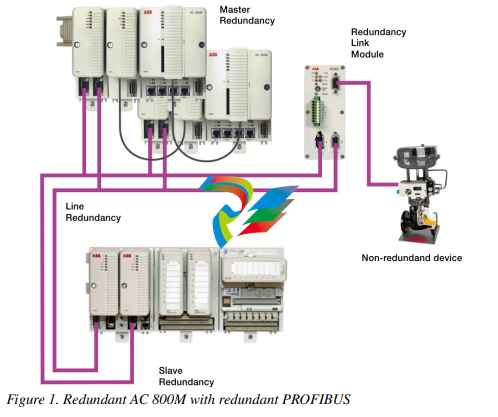

The following figure shows the redundant PROFIBUS connected to the redundant

AC 800M controller

Section 2 Functional Description

PROFIBUS Basics

Basic Functions DP-V0

Cyclic Data Communication

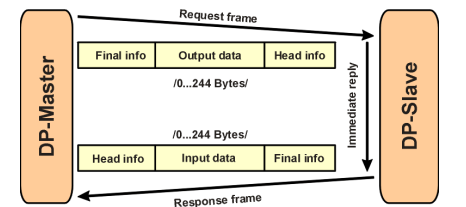

The data communication between the DPM1 (DP Master Class 1) and its assigned

slaves is automatically handled by the DPM1 in a defined, recurring sequence. With

each user data transfer, the master can write up to 244 bytes of output data to the

slave and read up to 244 bytes of input data from the slave. The Data is read and

written synchronously in one procedure

The assignment of the slaves to the DPM1, CI854/CI854A in this case, is done via

the HW configuration in Control Builder M.

The data communication between the DPM1 and the slaves is divided into three

phases: parameterization, configuration and data transfer. Before the master

includes a DP slave in the data transfer phase, a check is run during the

parameterization and configuration phase to ensure that the configured setpoint

configuration matches the actual device configuration. During this check, the device

type, format and length information and the number of inputs and outputs must also

correspond. This provides you with reliable protection against parameterization

errors.

Diagnostics

In addition to the cyclic data the PROFIBUS slave unit provides diagnostic data.

With this diagnostic data the slave can indicate errors or warnings on the slave unit,

the I/O-units or the I/O-channels. Some diagnostic data is generic and defined by the

PNO. But most of the diagnostic data is manufacturer specific.

The following errors/warnings are examples for PROFIBUS diagnostics:

Channel related:

– Wire break

– Short circuit

Module related:

– Wrong module type

– Module missing

Slave related:

– Power supply 2 error

– Internal bus error

The CI854/CI854A supports the operation of PROFIBUS DP-V0 diagnostics. The

diagnostic data transferred from the slave to the master is mapped by the

CI854/CI854A to the unit status of the PROFIBUS slave unit or the related I/O-unit

and is indicated as error or warning in the UnitStatus in Control Builder M for the

specific unit.

Only that diagnostic data configured within the hardware definition file is operated

by the system. The configuration includes

– Selection of diagnostic to be operated by the system.

– Mapping of the diagnostic information within the diagnostic frame on

PROFIBUS to the specific HW unit (slave or I/O unit).

– Definition of the corresponding bit in the unit status for the specific

diagnostic information. Use of device specific codes in

ErrorsAndWarnings and ExtendedStatus.

– Definition if the diagnostic information shall be indicated as error or

warning.

– Definition of the presented text within unit status and alarm/event for the

specific diagnostic information.

– Definition if in addition an alarm or event shall be generated for the

specific diagnostic information. If yes also the severity has to be defined.

For S800 I/O and S900 I/O the configuration for the diagnostics is already specified

in the hardware definition files that are provided with the system. For other slaves

the configuration for PROFIBUS diagnostics can be done via the DeviceImport

Wizard. The Device Import Wizard provides a dialog to pick up the diagnostic data

from the GSD-file and map it to the DeviceSpecific and ExtendedStatus bits of the

HwStatus for the related slave unit or I/O-unit. The dialog also supports the

configuration of alarms/events based on the diagnostic data. For more information

please refer to the online help for the GSD Import Tool.

DP Master Class 1 (DPM1) and Class 2 (DPM2)

TheDP master class 1 is the master that is in cyclic data transmission with the

assigned slaves. To get into the cyclic communication the DPM1 has to configure

the slave before.

The DP master class 2 is used for engineering and configuration. It does not have

cyclic data transmission with the slave devices. Normally a DPM2 is only connected

temporarily to the bus. A DPM2 can have class 2 communication to the slave

devices before the slaves are configured via DPM1 and cyclic communication is

active.

System Behavior

For a DPM1 master the following operating states are defined:

Stop

No data communication between the DPM1 and the slaves.

The CI854/CI854A is of type DP master class 1 (DPM1) and class 2 (DPM2).

Clear

The DPM1 reads the input information of the slaves and keeps the outputs of the

slavs in a fail-safe state (“0” output).

Operate

The DPM1 is in the data transfer phase. In cyclic data communication, inputs are

red from the slaves and output information written to the slaves.

The reaction of the system to a fault during the data transfer phase of the DPM1, for

example a failure of a slave, is determined by the “Auto Clear Modus” defined via

the BP flag configuration in the settings tab for CI854/CI854A. If this parameter is