EMERSONWestinghouse Small Modular Reactor: Taking Proven Technology to the Next Level

Westinghouse Small Modular Reactor:

Taking Proven Technology to the Next

Level

Presented to the IAEA INPRO Dialogue Forum

Vienna, October 2011

Dr. Nick Shulyak

Westinghouse Electric Company

Westinghouse SMR - Market Overview

Market Informed Sizing – 225MWe

• Some market observations that contributed:

– Incremental base load additions typically range from 200 to 300

MWe - based on coal and combined cycle natural gas units

– Greenhouse gas emissions reductions such as coal retirements

average 150 to 250 MWe - based on actual shutdowns and recent

public announcements

• Allows Use of Existing Infrastructure of Non-Nuclear

Stations - Nuclear Option for Non-Nuclear Companies

• Provides Option for Small Underserved Markets

Aging Fossil Plants

District Heating

Remote Markets

Small Grid Markets

Desalinization

Process Heat

SMR Product Specification

Specifications

Thermal Output 800 MWt

Electrical Output >225 MWe

Passive Safety Systems No operator intervention required for 7 days

Core Design 17x17 Robust Fuel Assembly

8.0 ft / 2.4 m Active Length

< 5% Enriched U235

89 Assemblies

Soluble Boron and 37 Internal CRDMs

24 month refueling cycle

Reactor Vessel Size Outer Diameter: 11.5 ft / 3.5 m

Height: 81 ft / 24.7 m

Upper Vessel Package 280 Tons

Containment Vessel

Size Outer Diameter: 32 ft / 9.7 m

Height: 89 ft / 27.1 m

Fully Modular Construction

Reactor Coolant

Pumps 8 External, Horizontally-Mounted Pumps

Sealless Configuration

Steam Generator Recirculating, Once-Through, Straight Tube

Pressurizer Integral to Vessel

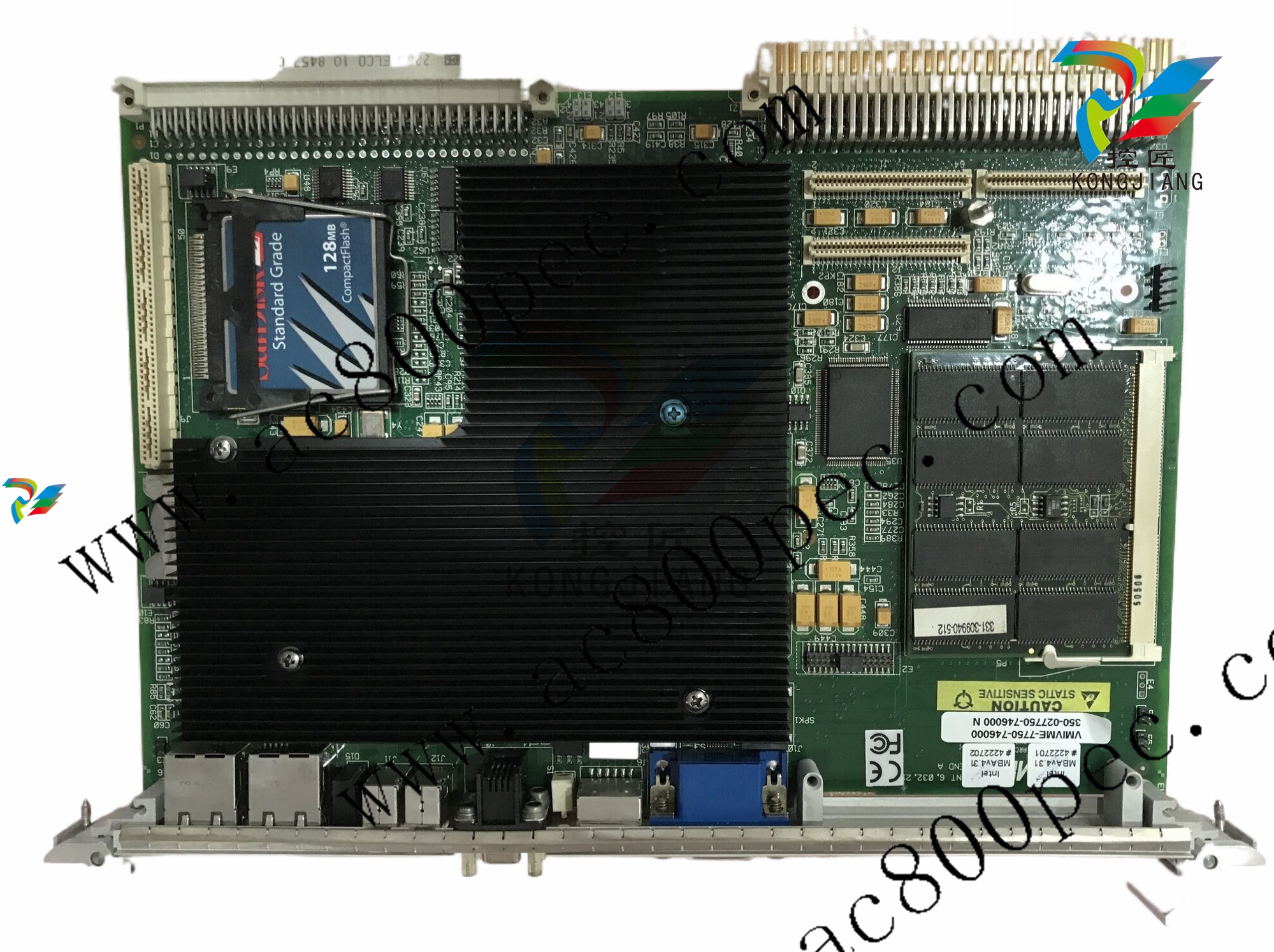

Instrumentation and

Control OVATION®-based Digital Control System

What It Is…

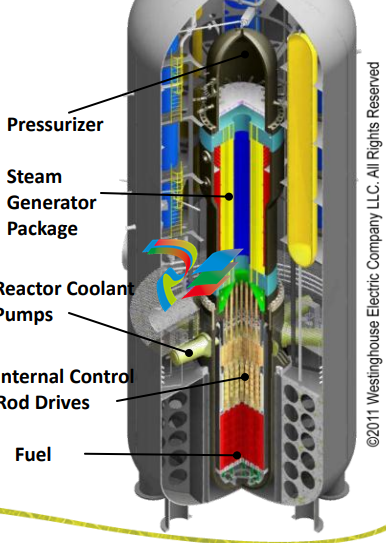

• An integral PWR

• Innovative packaging of proven

components

• The highest levels of safety with

fewer accident scenarios

• Industry-proven equipment designs

• Compact reactor coolant system and

containment

• An engineered solution for today’s

clean energy challenges

Pressurizer

Steam

Generator

Reactor Coolant

Pumps

Internal Control

Rod Drives

…Simplicity in Design

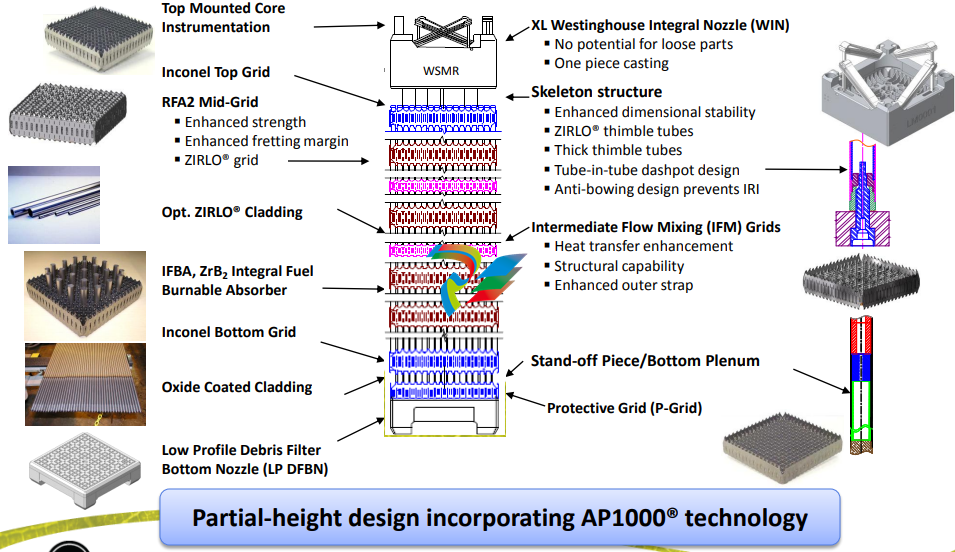

SMR Fuel Design: Proven Features, Ease of Licensing3

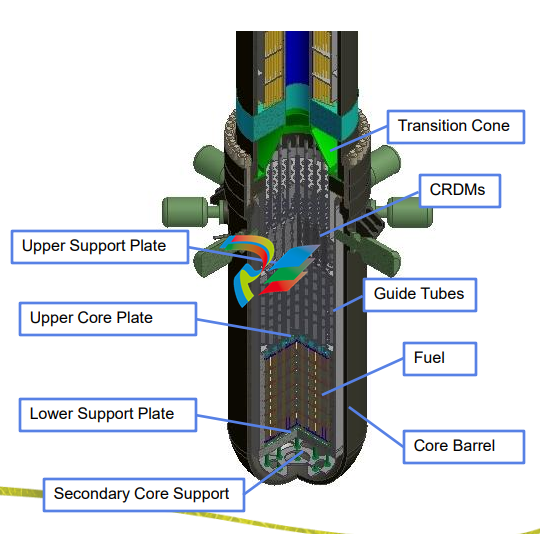

Westinghouse SMR Reactor Vessel Internals

• Design driven by

interfaces

– Steam generator

– Coolant pumps

– Reactor vessel

• Utilize AP1000®

component designs – e.g.

guide tubes, support

plates and columns, flow

skirt, vortex suppression,

etc.

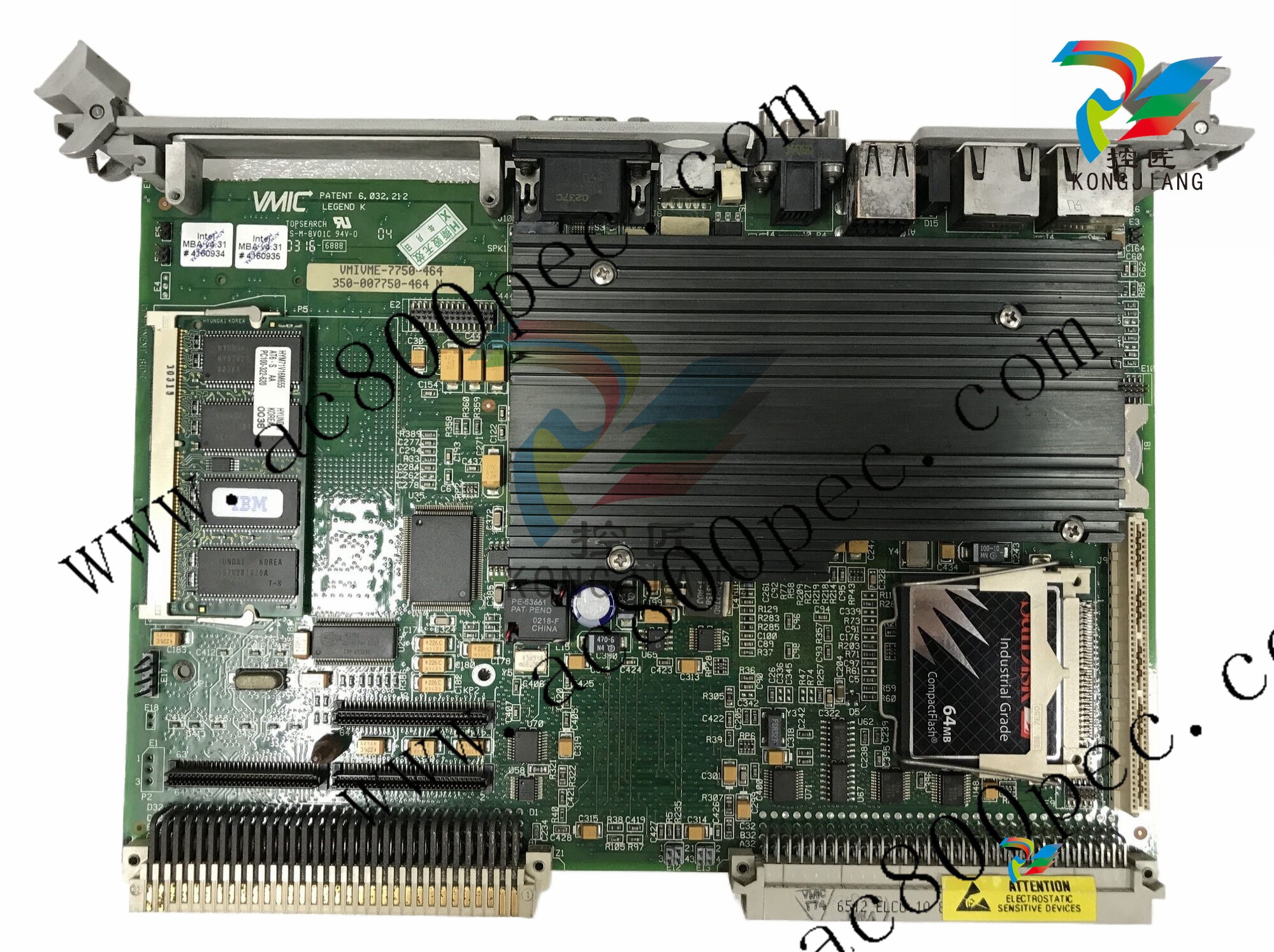

Integral CRDM Design

• Latch assemblies, controls, and interfaces with fuel are all

based on existing, proven designs

• Three-coil magnetic jack based AP1000® design

with modifications

– High-temperature

coil winding design

– Sealed, stainless steel

coil stack housing

– Sealed power conduit

with leak detection

• Test program initiated

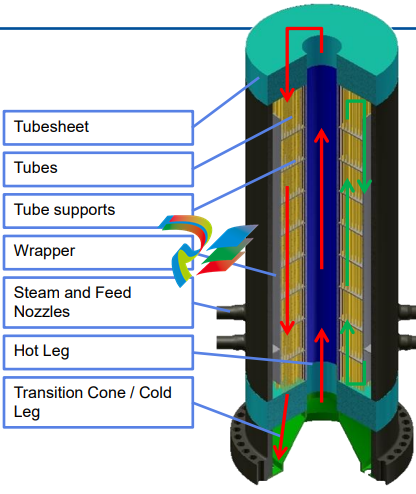

Recirculating Steam Generator

• Straight-tube steam generator

– Flow from top to bottom of tubes

• Hot leg located in center of tube

bundle

– Transfers hot water to the upper

tube sheet

• Main steam and two feedwater

piping connections

• Recirculating steam generator

with steam/water mixture

delivered to steam drum outside

containment

Steam Generator and Steam Drum System

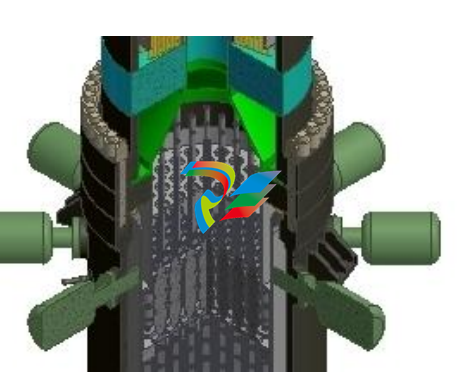

SMR Reactor Coolant Pumps

• Eight reactor coolant pumps

providing 12,500 gpm at 100 ft

of head (no seal injection)

• Each motor ~350 hp

– (460 V, 3 phase)

• Total flow 100,000 gpm

• Driven with 2 variable

frequency drives (VFD)

• Mount horizontally through

pressure boundary below

closure flange

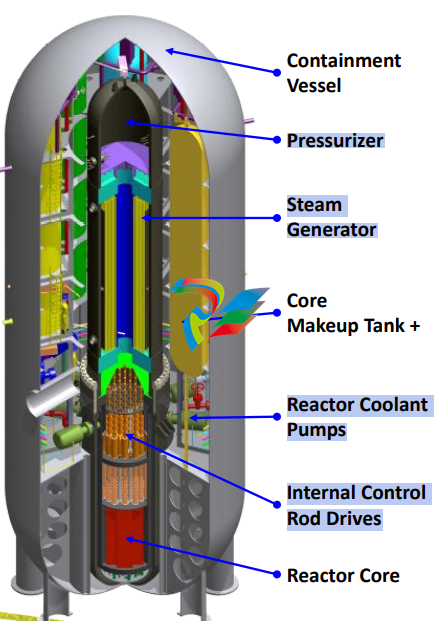

SMR Containment Vessel

• Compact containment

– High pressure

• Size 32-ft diameter and approximately

89-ft height

• Target is to operate containment at

vacuum to:

– Increase heat transfer inside containment

– Reduce insulation needs

– Reduce challenge of containment overpressure

• Water cooled on outside of containment

– Annulus flooded

• In vessel retention accomplished by draining

tanks of water to flood lower reactor vessel