DCS; Industrial control system

Product

Article

NameDescriptionContent

NEW CENTER

Current Location:

AI-Driven Automation Equipment: Paving the Way for a New Era of Intelligent Production

From:

|

Author:huang

|

Time :2024-11-12

|

207 Browse:

|

Share:

AI-driven automation equipment is playing a crucial role in shaping the new era of intelligent production. It represents a significant leap forward in the manufacturing industry, bringing together the power of artificial intelligence and advanced automation technologies.

The significance of AI-driven automation equipment cannot be overstated. In intelligent production, it enhances efficiency, reduces errors, and increases productivity. By automating repetitive tasks and processes, it frees up human workers to focus on more creative and strategic activities.

The basic concept of AI-driven automation equipment lies in the integration of artificial intelligence algorithms and mechanical systems. These algorithms enable the equipment to learn from data, make intelligent decisions, and adapt to changing production environments. For example, machines can detect patterns in production data and optimize their operations accordingly.

According to research, in the last ten years, automation has reduced the work force in some industries by half. This shows the powerful impact of automation on the job market. However, it also creates new opportunities for workers to upskill and engage in more high-value tasks.

AI-driven automation equipment is not limited to a specific industry. It is being applied in various fields such as manufacturing, healthcare, logistics, and agriculture. In manufacturing, it can be used for tasks like assembly, quality control, and inventory management. In healthcare, it can assist in surgeries, drug discovery, and patient care.

In conclusion, AI-driven automation equipment is a game-changer in intelligent production. It offers numerous benefits and has the potential to transform industries and economies. As technology continues to advance, we can expect even more innovative applications of AI-driven automation equipment in the future.

二、Benefits of AI-Driven Automation Equipment

(一) Enhanced Productivity

AI-driven automation equipment significantly enhances productivity. By minimizing manual intervention, these machines can operate continuously without the need for breaks or rest. According to industry data, factories that have implemented AI-driven automation equipment have seen a substantial increase in production output. For example, in some manufacturing plants, production rates have increased by up to 50%.

The optimization of processes is another key factor. AI algorithms can analyze production data in real-time and make adjustments to improve efficiency. This might involve optimizing machine settings, scheduling tasks more efficiently, or reducing downtime.

(二) Improved Quality Control

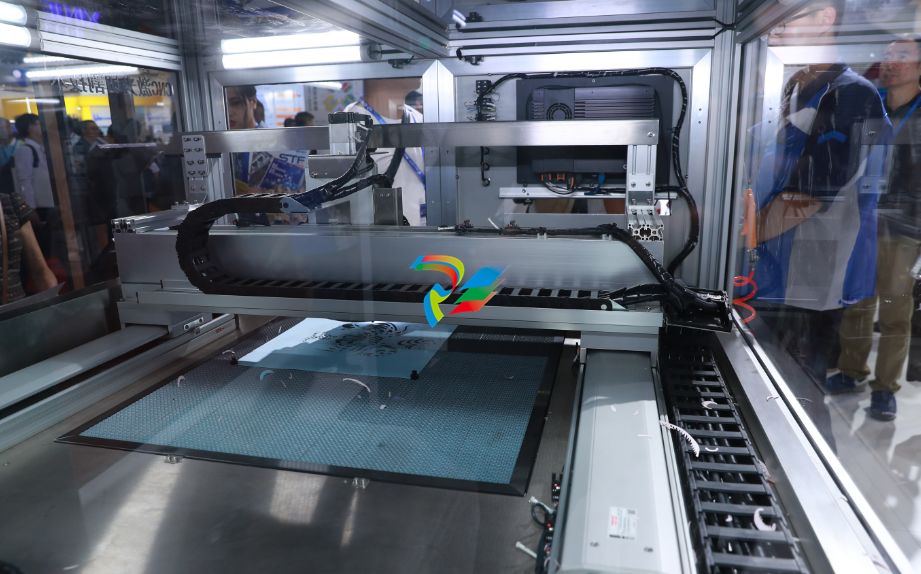

AI plays a crucial role in ensuring better product quality. Intelligent detection systems can identify defects and anomalies with a high degree of accuracy. For instance, in the electronics industry, AI-driven inspection systems can detect microscopic flaws that might be missed by human inspectors.

Through intelligent analysis, these systems can also predict potential quality issues before they occur. By analyzing patterns in production data, they can identify trends that might indicate a problem with a particular process or component. This proactive approach to quality control helps reduce waste and improve customer satisfaction.

(三) Flexible Production

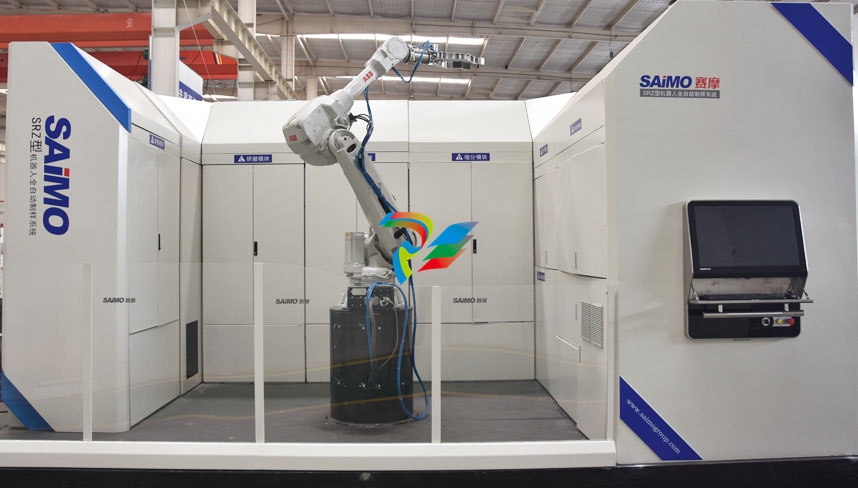

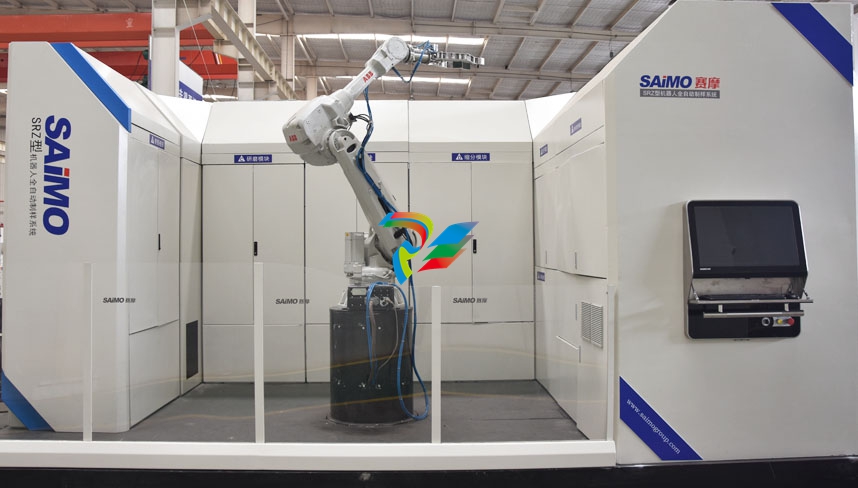

AI-driven automation equipment enables adaptive production to meet changing market demands. These machines can be programmed to switch between different products or production processes quickly and easily. This flexibility is essential in today's fast-paced business environment where customer demands can change rapidly.

For example, in the fashion industry, AI-driven production lines can quickly adapt to new styles and trends. They can produce small batches of customized products, allowing companies to respond to individual customer requests. This not only increases customer satisfaction but also reduces inventory costs and waste.

三、Technologies Behind AI-Driven Automation Equipment

(一) Artificial Intelligence in Manufacturing

Artificial intelligence has a wide range of applications in manufacturing. In process optimization, AI algorithms analyze large amounts of production data to identify inefficiencies and suggest improvements. For instance, by studying historical production data, AI can determine the optimal settings for machines to minimize waste and maximize output. In predictive maintenance, AI uses sensors and data analysis to predict when equipment is likely to fail. This allows manufacturers to schedule maintenance in advance, reducing downtime and saving costs. According to research, predictive maintenance can reduce equipment downtime by 30% to 50% and increase machine life by 20% to 40%. For example, in the automotive industry, AI-driven predictive maintenance systems can detect potential issues with production equipment, such as worn-out parts or overheating motors, and alert maintenance teams before a breakdown occurs.

(二) Digital Twin Technology

Digital twin technology plays a crucial role in helping monitor and optimize physical systems. A digital twin is a virtual replica of a physical object or process. It uses real-time data from sensors to mirror the behavior of the physical entity. In manufacturing, digital twins can be used to simulate and optimize production processes. For example, a digital twin of a manufacturing plant can be used to test different production scenarios and identify the most efficient configurations. By analyzing the performance of the digital twin, manufacturers can make informed decisions about optimizing production, reducing waste, and improving quality. In the aerospace industry, digital twin technology is used to predict the lifespan of aircraft engines and plan maintenance schedules. According to a study, digital twin technology can reduce production errors by up to 50% and improve product quality by up to 30%.

(三) Industrial Internet of Things

The Industrial Internet of Things (IIoT) connects and optimizes equipment and factories, enabling seamless communication and data sharing. Through the IIoT, sensors on machines and equipment can send real-time data to a central platform for analysis. This data can be used to monitor equipment performance, optimize production processes, and predict maintenance needs. For example, in a smart factory, IIoT sensors can track the production status of each machine, detect anomalies, and trigger alerts when necessary. The IIoT also enables remote monitoring and control of equipment, allowing manufacturers to manage production from anywhere. According to industry reports, the global IIoT market is expected to reach over $1 trillion by 2025. In the oil and gas industry, IIoT technology is used to monitor pipelines and equipment, reducing the risk of leaks and improving safety.

四、Examples of AI-Driven Automation in Practice

(一) Success Stories in Manufacturing

Some of the world's leading manufacturing companies have already reaped the benefits of AI-driven automation. For instance, a major automotive manufacturer implemented an AI-driven quality control system. By using machine learning algorithms to analyze images of car parts, the system was able to detect defects with an accuracy of over 95%. This not only improved product quality but also reduced the need for manual inspection, saving time and costs.

Another example is a consumer electronics company that adopted AI-driven automation in its assembly line. The system was able to assemble products at a much faster rate than traditional methods, while also ensuring consistent quality. According to the company, the implementation of AI-driven automation led to a 40% increase in production output and a significant reduction in defect rates.

In the pharmaceutical industry, an AI-driven automation system was used for drug packaging. The system was able to accurately package different types of medications at a high speed, reducing errors and improving efficiency. This not only ensured the safety of patients but also helped the company meet the growing demand for medications.

(二) Future Prospects

The future of AI-driven automation in manufacturing looks extremely promising. As technology continues to advance, we can expect to see even more sophisticated applications of AI and automation. For example, the development of more advanced machine learning algorithms will enable machines to learn and adapt even more quickly, leading to further improvements in productivity and quality.

However, there are also challenges that need to be addressed. One of the main challenges is the need for skilled workers who can operate and maintain these advanced systems. As automation continues to replace manual labor, there will be a growing demand for workers with skills in areas such as data analysis, programming, and robotics.

Another challenge is the issue of data security and privacy. As AI-driven automation systems rely on large amounts of data, there is a risk of data breaches and cyberattacks. Companies will need to invest in robust security measures to protect their data and ensure the integrity of their operations.

Despite these challenges, the potential benefits of AI-driven automation are too great to ignore. In the future, we can expect to see more companies embracing this technology and reaping the rewards of intelligent production.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)