Top 13 Innovative Technology in Construction for 2024

In 2023, the market size of the U.S. construction sector was valued at around $2.3 trillion. Though business is booming, the industry faces several challenges relating to materials costs, labor shortages, and operational inefficiencies.

The implementation of new construction technology is serving to alleviate these strains. Far from replacing traditional construction methods, these tools are augmenting the role of human workers and vastly improving outputs on job sites. For example, it’s projected that using robotics, artificial intelligence (AI), and the Internet of Things (IoT) could reduce building costs by up to 20%.

Here’s a rundown of 13 innovative technologies that are taking the construction industry by storm.

1. Augmented Reality and Virtual Reality

Yuganov Konstantin / Shutterstock.com

Typically powered using mobile applications, headsets, and other smart devices, augmented reality (AR) and virtual reality (VR) rose to prominence in the gaming industry, but they have numerous applications in construction.

While AR superimposes images generated by a computer onto its user’s view of the physical world, VR is an entirely computer-generated, immersive environment with which a user can interact in seemingly real or physical ways.

Both technologies are being used to enhance collaboration, improve on-site safety, train new hires, and drive project efficiencies. Key stakeholders benefit from virtual building tours, enabling them to remotely monitor their teams’ progress.

AR goggles scan labels and tags to provide workers with critical information — such as instructions for handling certain machinery or hazard information — which improves on-site safety.

VR and AR are used during employee onboarding, providing new recruits with a safe and engaging means to familiarize themselves with their new surroundings.

Increasingly, construction companies are implementing mixed reality (MR). This combines VR and AR to provide the best of both worlds: a truly immersive and engaging experience that allows users to stay in touch with their surroundings.

2. Construction Robots

Engineer studio / Shutterstock.com

Construction robots are used on building sites to increase accuracy, improve productivity, reduce accidents, and save costs.

The most common are demolition robots, which currently comprise 90% of the construction robot market. However, thanks to rapid advancements in AI and machine learning (ML), on-site robots are becoming more autonomous and more highly skilled.

Today, these machines are used for excavating and lifting heavy objects, bricklaying, welding, plastering, drilling, assembling, and 3D printing. A combination of increasingly affordable hardware and worker shortages is fuelling the growing demand for robots in construction.

Get more insights in our article “5 Ways Robots Are Assisting Construction Workers.”

3. Digital Twin

A digital twin is a virtual replica of a physical object, such as a machine or building, or a system, such as computer software.

The device integrates real-world data and other technologies, such as IoT and AI, to run simulations predicting how a product or system will perform. Often used for individual products, such as vehicles or machinery, digital twins can also be applied on a larger scale. For example, digital twin cities enable local governments to plan and manage public services.

In construction, digital twins are typically deployed to support asset management and space optimization, including who will use the space, how, when, and what assets will live there. In addition, the technology can test safety procedures and emergency action plans. For example, it would be possible to simulate a building evacuation to determine if additional exit routes are required.

A digital twin continues to be useful following a project’s culmination by supporting building management teams.

4. Artificial Intelligence and Machine Learning

AI and ML are proving invaluable throughout the entire construction process.

For starters, these technologies help construction firms design spaces that are optimized for human end-users and identify mistakes in a project plan that could lead to long-term problems. This drives operational efficiencies and lowers overall project costs.

When construction begins, AI and ML solutions are implemented to supervise daily operations, which ensures the safety of construction workers and enables project managers to monitor progress in real-time. In addition, AI- or ML-powered robots perform some of the most monotonous and labor-intensive on-site tasks, such as bricklaying and welding. This enables skilled professionals to focus on value-adding activities.

Construction companies leverage the data collected and analyzed by AI and ML solutions to continually enhance their operations. For example, an analysis of on-site video footage might highlight worker non-compliance or safety hazards. These tools also review historic building systems data to inform the design of future projects, enabling companies to optimize various performance metrics, such as energy efficiency and air quality.

Finally, AI and ML are used in predictive maintenance, highlighting when construction machinery or building systems, such as electrical systems, will require replacing or repairing. This prevents equipment failures, which can lead to project delays and increased costs.

5. Building Information Modeling

Building information modeling (BIM) is a construction technology used for planning, design, and development, providing construction professionals with an intelligent digital representation of the physical and functional characteristics of structures and buildings.

Before the advent of BIM, construction firms used 2D blueprints or, more recently, computer-aided design (CAD) to map out building plans. However, these technologies had their limitations, making it difficult for stakeholders to visualize requirements and measurements and access granular detail.

A BIM tool, on the other hand, provides users with accurate and agile 3D models and includes information about parts and materials, finance, logistics, and procurement.

Today, the technology is deemed so essential that it is sometimes mandated for construction projects. Not only does BIM ensure efficiency, quality, and safety, but it also drives collaboration among architects, engineers, real estate developers, contractors, and manufacturers, who can share information via a common data environment (CDE).

6. Blockchain Technology

Three major challenges in the construction industry are transparency, accountability, and inefficiency, not least because projects so often involve multiple stakeholders and subcontractors with conflicting priorities and requirements. Blockchain technology — which enables transparent information sharing within a business network — addresses these challenges in several ways.

Firstly, it enables seamless tracking of products and materials across even the most complex of supply chains, highlighting issues such as theft and fraud.

Secondly, blockchain facilitates timely and cost-effective money transfers between multiple parties and across different regions. This is particularly beneficial when different stakeholders require different forms of payment. The technology ensures that every transaction — and its associated data — is tracked and logged securely and transparently. Increasingly, BIM and blockchain technology solutions are being integrated to support a more robust contracting process.

Thirdly, the technology can track safety violations that occur on construction sites to ensure contractors are held accountable. Any data relating to a violation will be stored on a blockchain.

Finally, blockchain-powered project management platforms record all project data to enhance cross-team collaboration and drive operational efficiencies.

7. Drones

Gorodenkoff / Shutterstock.com

The construction sector has experienced a 239% growth in drone use year over year, with companies leveraging these devices for land and site analyses, planning and design, equipment tracking, project reporting, security surveillance, and cross-team collaboration.

Drone usage lowers costs, drives operational efficiencies, reduces risk, and improves data accuracy. For example, surveying a large job site using human workers is time-intensive and labor-intensive. Drone surveyors, however, can cover 120 acres of land each hour, which equates to a 60-fold improvement in surveying efficiency.

This saves money since less labor is required while helping companies adhere to strict project deadlines. In addition, since drones can access hard-to-reach and hazardous areas, they offer a safer means of site monitoring and data collection.

8. 3D Laser Scanner

A 3D laser scanner uses specialized software and a laser probe to capture a physical object’s exact size and shape as a digital 3D representation.

The technology’s ability to measure minute details and create highly accurate point clouds means it is perfectly suited to a construction site’s contoured surfaces and complex geometries.

Indeed, the demand for 3D laser scanning in the construction industry is expected to grow by $10 billion by the end of 2024.

The technology proves useful throughout a project’s life cycle — from design and construction to operations and renovations. As well as improving accuracy, reducing manual labor, driving collaboration, and enhancing critical project data collection, 3D laser scanners can lower costs by 50% compared to 2D scanning.

Despite the many benefits associated with laser scanning, upfront costs are high, and skilled workers are required to operate the technology.

9. 4D Building Information Modeling

A 4D BIM model consolidates 3D BIM models created during a specific time period to produce a virtual construction sequence. Put plainly, 4D BIM provides a simulation of construction activities over time.

The technology provides full visibility of a project and the teams working on it, enabling project leads to monitor progress, keep large projects on schedule, identify errors, and make informed decisions regarding the future of a project.

Today, the construction sector most commonly uses the technology to win subsequent project bids since it is a great way to showcase historic work. Some teams are also using it to optimize processes and reduce costs.

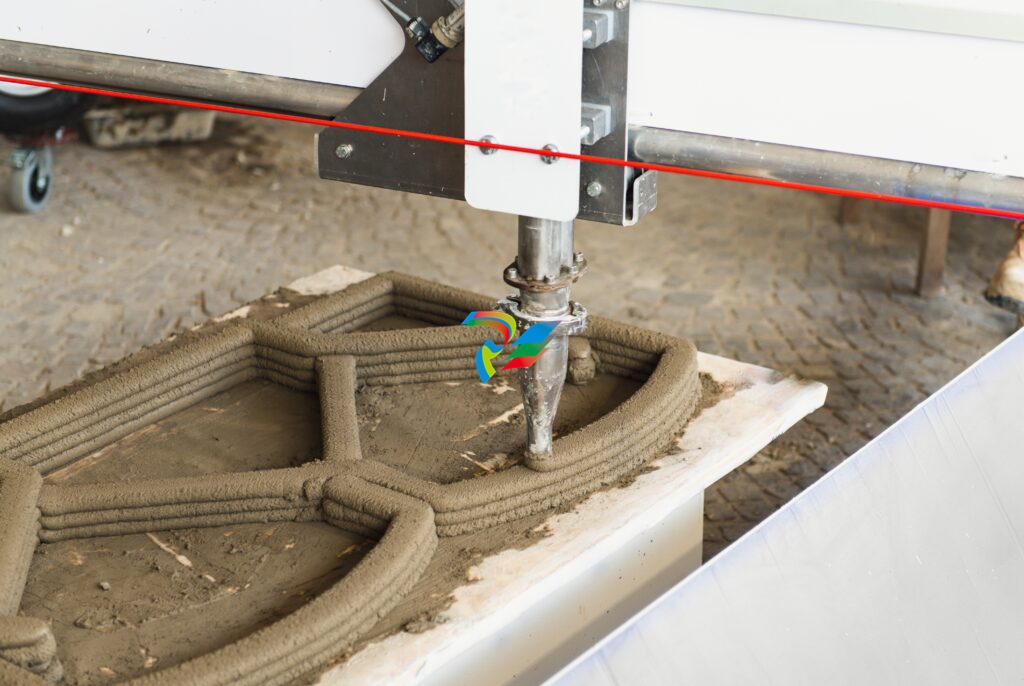

10. 3D Printing

Fabio Pagani / Shutterstock.com

It’s no exaggeration to say that 3D printing is revolutionizing the construction sector.

For starters, 3D printing renders project-halting component shortages a thing of the past. As long as appropriate raw materials are available, construction workers can print whatever they need whenever they need it.

This technology is also supporting the shift to sustainable construction by enabling a precise amount of material to be used and reducing on-site waste by up to 60%. Even last-minute design choices won’t result in additional waste; fine-tuning of designs and product customization can occur right up until the point of construction.

Additionally, 3D printing reduces construction workers’ exposure to risk by taking on formerly manual tasks.

11. Resource and Workforce Management Software

Resource and workforce management software typically helps companies streamline and automate processes relating to personnel, such as forecasting, staffing, and scheduling.

In construction, the pace of change is fast and project leads must juggle multiple stakeholders and contractors at any given time. Labor shortages, safety compliance issues, and scheduling conflicts present further challenges. A resource or workforce management tool alleviates these pressures by supporting communication, planning, data management, rostering, and actuals.

It optimizes the existing workforce by ensuring the right people are in the right place at the right time, consolidates critical workforce data into a centralized system to enable informed decision-making, and manages project timelines and budgets. In addition, these solutions can significantly reduce work-related accidents via effective on-the-job training.

12. Sensor Data

Sensor data is generated when a sensor device detects input from the physical environment surrounding it and provides a response. Typically, that response—or output—is used to relay important information to an end user.

In construction, sensor data plays a vital role in ensuring the safety of on-site workers and future inhabitants of a space. To provide a few examples:

Vibration sensors detect movement within structures to warn of stability issues

Humidity sensors monitor environmental conditions to prevent damage to materials

Gas sensors monitor the levels of certain elements in the air to warn of air pollution

Proximity sensors detect the presence or absence of a nearby object or material to warn of hazards

Increasingly, sensor data devices possess wireless connectivity, which enables remote monitoring and control.

13. Advanced Takeoff and Estimating Tools

In an age when rapidly rising materials costs and increasingly thin profit margins are placing huge pressures on the construction industry, meticulous budgeting is paramount.

That’s where advanced takeoff and estimating technologies come in handy. The former identifies and quantifies the tools, materials, and labor required for a construction project, while the latter calculates the costs associated with each of these project components.

The software enables team leads to accurately plan and budget projects to ensure resources are effectively allocated and client bids are more competitive. While takeoffs and estimations can be carried out manually, digital tools offer a substantial return on investment (ROI) since they are more accurate and efficient, increase collaboration, and reduce costs.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)