ABBAutomatic Transfer Switch

1. Symbols & Terms

1.1 Use of symbols

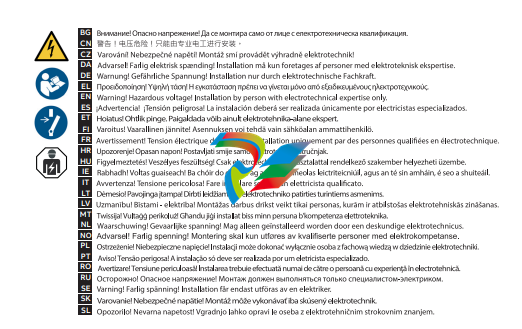

Risk of Electric shock: warns about a situation where a hazardous voltage may cause physical injury to a person or damage to equipment.

General warning: warns about a situation where something other than electrical equipment may cause physical injury to a person or damage to equipment.

Caution: provides important information or warns about a situation that may have a detrimental effect on equipment.

Information: provides important information about the equipment

Risk of Electric shock: warns about a situation where a hazardous voltage may cause physical injury to a person or damage to equipment.

General warning: warns about a situation where something other than electrical equipment may cause physical injury to a person or damage to equipment.

Caution: provides important information or warns about a situation that may have a detrimental effect on equipment.

Information: provides important information about the equipment

1.2 Explanations of abreviations and terms

OTM_C21D Automatic transfer switch, the type name

LN1-Switch I Power supply line, e.g. the primary line

LN2-Switch II Power supply line, e.g. the secondary line used in emergency cases

EMRG OFF Used to drive the automatic transfer switch transfers to the “O” position when receiving EMRG OFF signal

AUTO Automatic mode

Remote test A sequence to test the functionality of the automatic transfer switch

Ts Transfer delay

TB s Return delay

OV Adjustable overvoltage threshold

UV Adjustable undervoltage threshold

2. Product overview

2.1 Product overview and packing

The OTM_C21D automatic transfer switch can be

used as a source transfer switch in a three-phase

or single-phase networks. Monitored conditions are,

no-voltage, phase-loss, overvoltage and undervoltage

detection, transfer delays, generator start and stop, and

remote test function. Source transfer can be performed

using a manually

operated handle, locally using push buttons or fully automatically. The automatic mode includes several operating methods: Line 1 priority, no line priority and manual back switching mode. OTM_ C21D can achieve communication function by using the optional external Modbus RTU module.

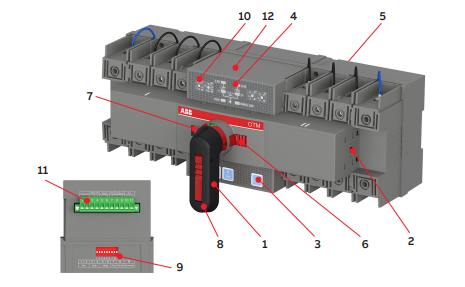

1. Handle for manual operation

2. Place for auxiliary contact blocks

3. Push button

4. Mimic panel

5. Voltage sensing connections

6. Locking clip for padlock

7. Locking latch for releasing the handle and locking electrical control

8. Locking clip for locking manual operation

9. Dip switches

10. Rotary switches

11. Connecting terminal

12. Modbus RTU acces

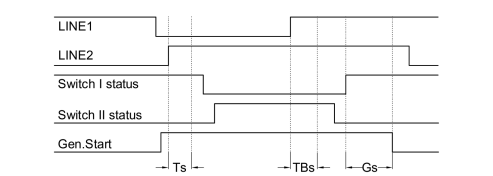

2.2 OTM_C21D switching sequence

2.2.1 Line 1 Priority (default mode)

The transfer sequence of OTM_C21D can be summarized in following steps:

• An anomaly occurs on the Line 1 (LN1)

• Generator start, immediately start generator in case of black-out, phase-loss, overvoltage or undervoltage (If Generator mode is selected)

• The Line 2 start the normal functioning, transfer delay Ts

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start the normal functioning

• Return delay TBs

• Change-over switch (Switch II) to the position 0

• Change-over switch (Switch I) to the position I

• Generator stop delay Gs

• Generator stop

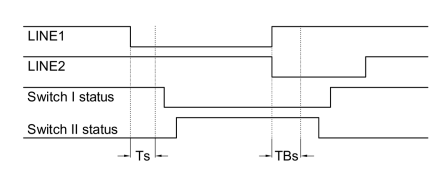

2.2.2 No line priority

The transfer sequence of OTM_C21D can be summarized in following steps:

• An anomaly occurs on the Line 1 (LN1)

• Transfer delay Ts, in case of black-out, phaseloss, overvoltage and undervoltage conditions

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start the normal functioning

• Change-over switch stays in position II • An anomaly occurs on the Line 2 (LN2)

• Return delay TBs

• Change-over switch (Switch II) to the position 0

• Change-over switch (Switch I) to the position I

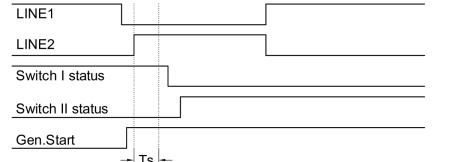

2.2.3 Manual return mode

The transfer sequence of OTM_C21D can be summarized in following steps:

An anomaly occurs on the Line 1 (LN1)

• Generator start, immediately start generator in case of black-out, phase-loss, overvoltage or undervoltage (If Generator mode is selected)

• The Line 2 start the normal functioning, transfer delay Ts

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start t

• Change-over switch stays in position II

• An anomaly occurs on the Line 2 (LN2)

• Change-over switch stays in position II

• Change-over switch can be transferred manually back to position I

3. Quick start

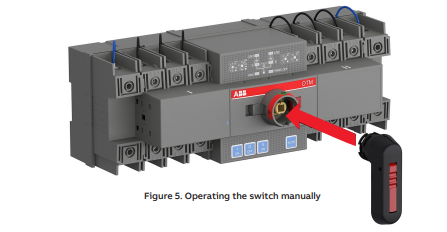

3.1 Operating the switch manually (local operation)

To operate the switch manually:

1.Attach the handle to the switch panel. You can attach the handle in any position.

2.When the handle is attached, the automatic transfer switch will automatically be in

Manual

mode and won’t operate automatically in case

of line failure. The AUTO LED on the mimic panel

is OFF.

When the handle is inserted into the switch, the switch will enter “manual mode” with the automatic operation disabled.

Do not adjust wires when the transfer switch is being energized.

Before the power-on operation of the transfer switch, please operate the switch manually to confirm it is in normal function.

With the power supply function in “normal” and without the handle inserted and EMRG OFF signals, the initially energized switch will enter automatic mode and transfer to the main line. Keep the handle inserted if you do not want the switch to be in automatic mode upon initial energization

—

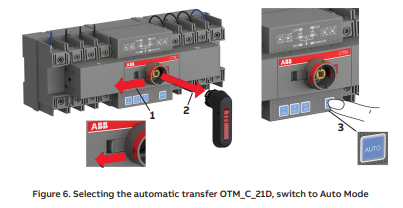

3.2 Automatic operation

OTM_C21D must be in automatic mode and the “AUTO” LED is on

in order that the switch can perform automatic transfer cycles according

to

the pre-set operating mode.

To operate the switch electrically: • If the handle inserted

1. Press handle locking clip and remove the handle from the switch.

2. Press “AUTO” button and the “AUTO” LED will be ON, indicating automatic mode.

• If handle is not inserted

1. If “AUTO” LED blinks, press “AUTO” button and the “AUTO” LED will be ON, indicating automatic mode.

2. Automatic operation includes three operating modes: Line 1 priority (factory default setting), No line priority, and manual return mode.

3.3 System testing

3.3.1 Local test

In automatic mode, “AUTO” LED is ON and you can transfer the switch using

I, O, and II push buttons on the front panel of the switch. Press “AUTO” button

to return the automatic

operation.

3.3.2 Remote test

The procedure of the remote test is as follows:

1. Connect to the remote test signal according to Figure 7.

2. Ensure that the OTM_C21D is in automatic mode (“AUTO” LED is on).

3. Short circuit the remote test signal for at least 100 ms until the “AUTO” LED blinks to enter the test mode. Under test mode, the automatic transfer switch will simulate switching cycle and finally return to its original position prior to the activation of the test mode. e.g., when the switch is in Position I: Enter test signals; the switch transfers to Position O → to Position II → to Position O → to Position I. Entering test signals is invalid before the automatic transfer switch returns to its original position. Under test mode, press the “AUTO” button to cancel test mode and return to automatic mode. The “Auto” LED will be “ON” as normal.

4. After the remote test finishes, the OTM_C21D automatically returns to the automatic mode (“AUTO” LED is on).

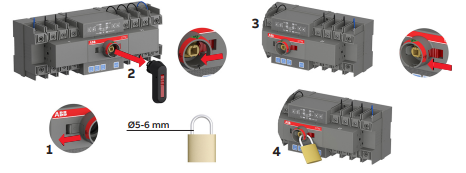

3.4 Locking

3.4.1 Locking the electrical operation

The switch can be padlocked in any position,

causing that all operating modes and test

operations are disabled, and handle cannot be

inserted. See below for operation:

Figure 8. Locking the electrical operation

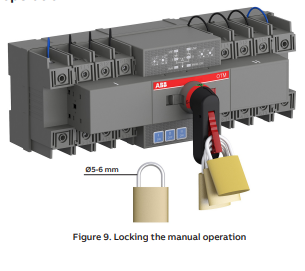

3.4.2. Locking the manual operation

By default, the manual operation can only be locked in position 0. The handle can be padlocked by pulling out the clip from the handle and place the padlock on the handle see Figure 9

3.5 Modbus communication function

OTM_C21D can achieve communication function

by using the optional external Modbus RTU

module.

3.5.4 Cyber security

Disclaime

t is the sole responsibility of the customer to provide and continuously ensure a secure connection between the product and the customer network or any other network. The customer is required to establish and maintain any appropriate measures (including but not limited to the installation of firewalls, application of authentication measures, encryption of data, installation of anti- virus programs, etc.) to protect the product, the network, its system and the interface against any kind of security breach, unauthorized access, interference, intrusion, leakage and/ or theft of data or information. ABB and its affiliates are not liable for damage and/or losses related to such security breaches, unauthorized access, interference, intrusion, leakage and/or theft of data or information.

Secure

Deployment

The user of the product should be aware that the unsecure nature of the serial Modbus protocol exposes the communication between the product and the control system. Encryption, authentication or integrity of transmitted data are not provided by the protocol. To prevent equipment to operate in an unsafe or undesirable manner due to malicious activities the product must be positioned in a trusted network, strictly limited and in a hosted portion of a network or control system. The recommendation is also to restrict physical access to the product/ system to only allow authorized people to make changes to the system. Besides, the user can setup system to trigger alarm when communication is interrupted (device stops responding) and check if there are any unsafe condition

4. Interface and Settings

4.1 Buttons

Figure 11. Buttons

Button Function Remarks

I ON Transfer to LN1 Only available in automatic mode and remote test mode

O OFF Transfer to 0 position

II ON Transfer to LN2

Auto Select autiomatic mode, fault clearance and reset

Table 5. Buttons

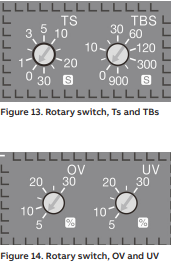

4.3 Rotary switch settings

Transfer delay Ts The delay of transferring from the LN1 to the LN2 in automatic mode.

The options are 0, 1, 2, 3, 5, 10, 15, 20, 25, and 30 seconds.

Return delay TBs The delay of transferring from the LN2 to the LN1 in automatic mode.

The options are 0, 5, 10, 20, 30, 60, 120, 300, 600, and 900 seconds.

Overvoltage threshold OV (%) and undervoltage threshold UV (%) The benchmarks of the OV

and UV are the rated voltage of the switch. When the voltage is higher than the pre-set OV value

or lower than the preset UV value, the switch performs automatic transfer.

The value of OV can be 5%, 10%, 15%, 20%, 25%, and 30%. The

value of UV can be 5%, 10%, 15%, 20%, 25%, and 30%.

4.4 Dip switch setting

The 9-bit dip switch is used to set the working

modes of transfer switch.

4.5 Terminal outputs and inputs

The switch has 11 bits of signal terminals for users to input and output signals

Figure 16. Terminals

Terminal

No. Function

1, 2 Remote test: connection for at least 100 ms for the switch to enter the remote test mode

3, 4 EMRG OFF: Input the 24VDC EMRG OFF signals for at least 1s until the switch transfers to the EMRG OFF

position and the EMRG OFF LED is on. At this time, the switch cannot enter the automatic or test mode and only handle operation is allowed. After the signal is canceled, press "AUTO" to quit EMRG OFF

5, 6 Generator start: generator start signal output. When the backup power is a generator, it is used to start (close signal) and stop (open signal) the generator. After the switch transfers to the normal power, the generator stop signal is sent after the preset delay for generator stop (see the ninth bit in section 4.4 for the generator stop delay setting).

7,8,9 Switch status feedback signal output.

10, 11 Alarm: The switch outputs consecutive alarm signals in EMRG OFF mode or refuses to perform operations. The alarm signals are cleared after quitting the EMRG OFF mode, fault recovered, or handle inserted.

Output Output contact relays are dry contactz and therefore external voltage supply is required.

contacts 24VDC or up to 250VAC max. 3A AC1

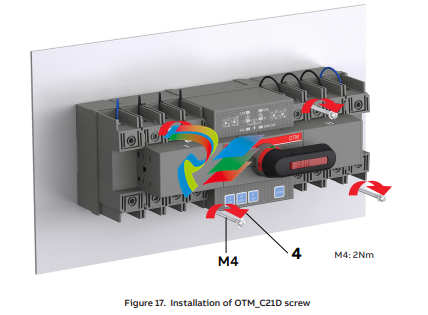

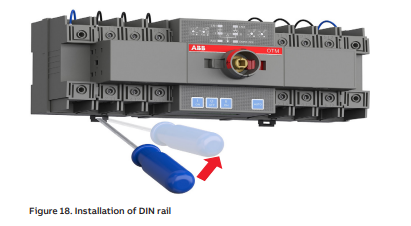

6. Installation

6.1 Installation method

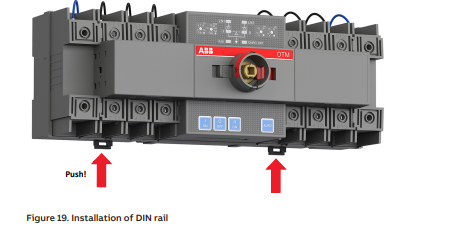

The switch can be installed using screws or a DIN rail. The fixed installation mode on the base board is as follows:

The DIN rail installation mode is as follows: First pry out the latch with an appropriate tool, as shown in Fig. 13

After attaching the switch to the DIN-rail, push the latch back to lock it

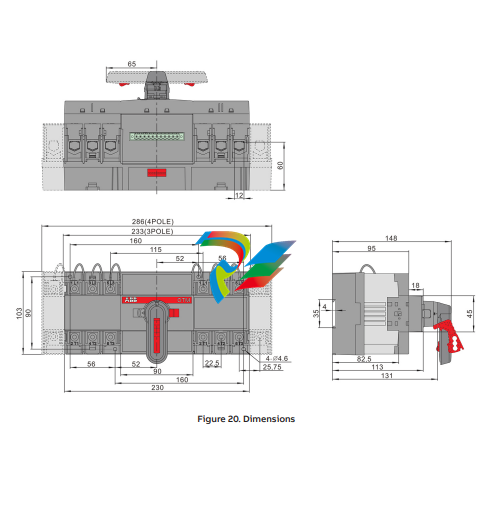

6.2 Installation dimensions

7. Optional accessories

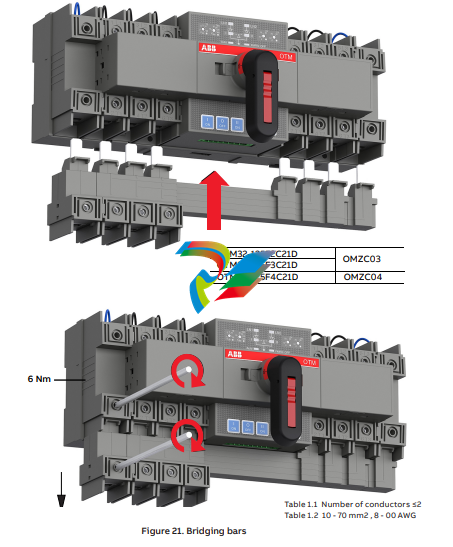

7.1 Bridging bars

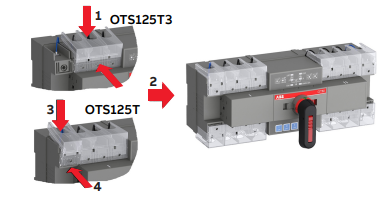

7.2 Terminal shrouds

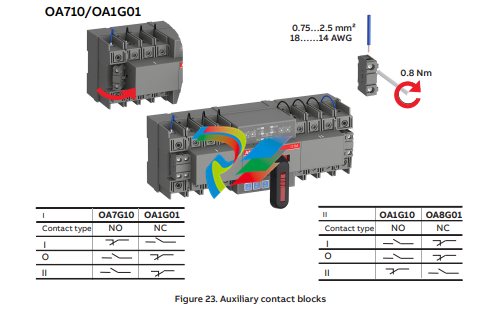

7.3 Auxiliary contact blocks

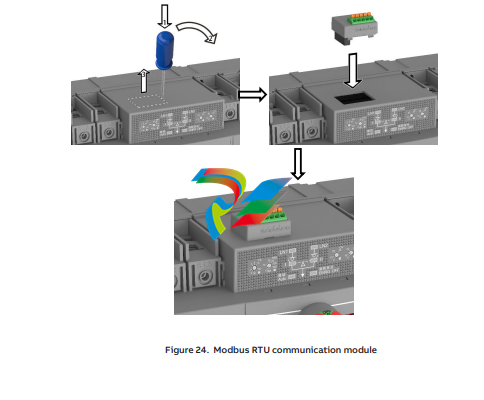

7.4 Modbus communication module

8. Maintenance and common

troubleshooting

8.1 Maintenance

To ensure the operation reliability of switches, regular switching tests should be performed (once

every 3 months) to confirm normal function.

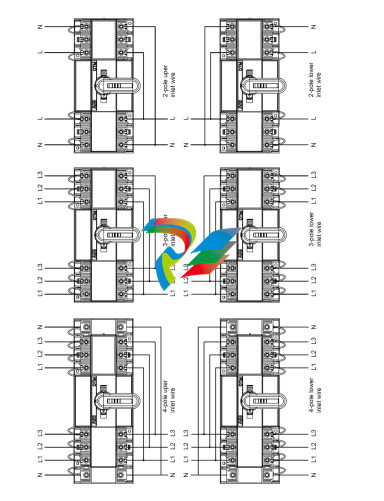

9. Appendix9.1 Wiring diagram

• Read through this instruction book carefully before working on the switch, and keep this instruction book safe for later reference

• The images provided in this instruction book are for illustration only and may not match the actual product exactly

• This instruction book is subject to change for product updates without prior notice

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)