ABBEasyLine EL3000 Series

Measurement made easy So smart, they’re simple

—

A wide variety of measurement technology Ů Detectors for multiple process and emission monitoring applications Ů Up to five sample components in one gas analyzer Ů Suitable for measuring flammable gases Ů Version in Category 3G for measuring non-flammable gases Ů Performance-tested for emission monitoring according to EN 15267 Ů QAL3 monitoring according to EN 14181 (optional)

—

Straightforward handling Ů Automatic calibration including control of pump and solenoid valves Ů Simplified calibration with air or integral calibration cells eliminating the need for test gas cylinders Ů Self-monitoring function indicates when maintenance is required

—

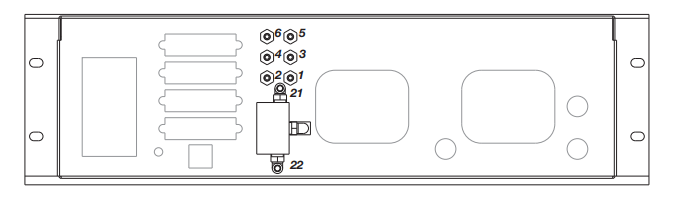

Application-oriented design Ů Housing design for 19-inch rack mounting or wall mounting Ů Integrated pneumatics module in model EL3020 (optional) Ů Ethernet, Modbus and PROFIBUS interfaces Ů Configurable analog outputs and digital inputs/outputs

—

User-friendly operation Ů Simple operator interface Ů Clear-text status messages Ů Configuration of seldom required functions with configuration software

Overview of the gas analyzers Measuring technology (analyzers)

The following analyzers are available for selection:

Uras26 infrared photometer for the measurement of infrared-active gas components, e.g. CO, NO, SO2

• Limas23 ultraviolet photometer for the measurement of NO, NO2 and SO2 • Magnos206 oxygen analyzer for the measurement of O2 in process gas or in N2

• Magnos28 oxygen analyzer for the measurement of O2 in process gas or in N2

• Magnos27 oxygen analyzer for the measurement of O2 in flue gas or in N2

• ZO23 trace oxygen analyzer for the measurement of O2 in pure gases (N2, CO2, Ar)

• Caldos27 thermal conductivity analyzer for the measurement of binary gas mixtures with different thermal conductivity, e.g. Ar in O2, H2 in Ar, CH4 in N2

• Fidas24 flame-ionization detector for the measurement of hydrocarbons

• Electrochemical oxygen sensor for the measurement of O2 Magnos206 and Magnos28 can also be used in combination with Uras26 or Limas23. Magnos27 and Caldos27 can also be used in combination with Uras26. Fidas24 and ZO23 cannot be used in combination with one of the other analyzers. The electrochemical oxygen sensor can only be used in combination with Uras26 or Limas23. Two electrochemical oxygen sensors can be used in combination with Uras26 with separate gas paths (only in model EL3020). Each analyzer has one physical measurement range per sample component. A section of the physical measurement range can be mapped to the current output (analog output) by on-site configuration. Calibration is always executed in the physical measurement range. The permissible measurement range limits are given by the specification of the smallest and largest measurement ranges for the individual analyzers. A total of up to five measurement components can be measured with one gas analyzer.

Calibration

Calibration can be performed automatically or manually or externally controlled via the Modbus. Automatic calibration – for all sample components together – is normally started on a cyclically time-controlled basis; it can also be started by an external control signal or via the Modbus as well as manually on the display and operator control unit of the gas analyzer. Normally, simplified calibration methods with the built-in calibration cells or the so-called single-point calibration are used for automatic calibration. If calibration with test gases is required the control of solenoid valves for switching on five test gases, z

Concept of operation

The functions required in normal operation are operated and configured directly on the gas analyzer. The functions which are only seldom required, e.g. during startup, are configured offline using the configuration software ECT (“EasyLine Configuration Tool” on the enclosed DVD-ROM) and then loaded into the gas analyzer.

QAL3 monitoring

QAL3 monitoring is available as an option in the gas analyzer. It is used to fulfill the requirements according to EN 14181 for storage and analysis of device adjustment data. The QAL3 monitoring option features the following functions:

• Automatic acquisition, verification and documentation of drift and precision at zero and reference points

• Reporting via CUSUM and Shewhart control charts

• QAL3 data storage in the gas analyzer (maximum 1 year)

• QAL3 data display and read-out as well as parameter setting via web browser

• Status messages on deviations beyond requirements

• Data export for further processing with spreadsheet programs

Electrical interfaces

The electrical interfaces for the output of measured values and communication with external systems include

• The integrated Ethernet-10/100BASE-T interface for – gas analyzer configuration with configuration software ECT – QAL3 data transfer if the QAL3 monitoring option is integrated in the gas analyzer – data transmission with Modbus TCP/IP protocol (measured values, status signals and control signals) as well as the integrated I/O modules depending on the functional range and order Profibus module with one RS485 and one MBP interface (also according to VDI 4201 Part 2), Modbus module with one RS485 and one RS232 interface (also according to VDI 4201 Part 3), Digital I/O module with four digital inputs and four digital outputs, 2-way analog output module with two analog outputs, 4-way analog output module with four analog outputs.

.png)

.png)

.png)