EMERSONWestinghouse Nuclear Automation

– Steam Dump or Steam Bypass – Reactor Pressure Regulation

– Feed System Feed System

– Steam System

– NSSS (core)

● Evaluation response over the full range of operation and

operational transient conditions

– Normal Operation

– Contingency Operations

● Provides high confidence set of initial tunings

● Pr

ovides

a basis for v

alidati

on

of desig

n

Feed Water Control Design Overview

- Example

● S/G Model Description Example

– Nodes of S/G Model

Feed Water Control Design Overview Example

Nodes of S/G Model

– Primary side tubes

– Secondary side tube bundle area (inside of wrapper)

– Riser section (from bundle exit through primary separators) Riser section (from bundle exit through primary separators)

– Upper downcomer (generally downcomer area from start of transition cone to top of primary separators)

– Lower downcomer (straight cylindrical portion of downcomer belo transition cone) below transition cone)

– Steam dome (region above top of risers or primary separators)

– Separate mass/energy balances for exit properties

– Momentum balance performed to calculate change in

various section flow rates

Feed Water Control Design Overview Feed Water Control Design Overview

- Example Example

● Proven Validation Approach

– SWIL (

S

oft

ware In

Loop) l d l lid ti t ti ) close

d loop valid

ation

testing

with plant specific model ensures realistic plant

operational response

–

ACSL Models validated for various SG’s and now

Reactor Vessels (BWR)

Westinghouse

B&W Canada (5 Units)

AREVA (5 Units)

C b ti E i i (4 U it ) Com

bustion

Eng

ineering (4

U

nits)

GE BWR 6 Reactor Vessel – Clinton and River Bend

Feed Water Control Design Overview Feed Water Control Design Overview

- Example Example

● Proven Control Application

– SWIL l d SWIL close

d

-l l oop, real-ti t ti id lid ti time

testing provides valid

ation,

allows integration test of graphics, alarms and controls with

plant operators before system is manufactured

Setpoints verified for operational transients

(determined previously with ACSL control system

models)

Dynamic set points (Gain, Integral & Derivative) for PID

are carefully chosen

For responsiveness to transients For responsiveness to transients

For near steady state conditions

Results in no tuning during plant startup

Software In Loop (SWIL) Software In Loop (SWIL)

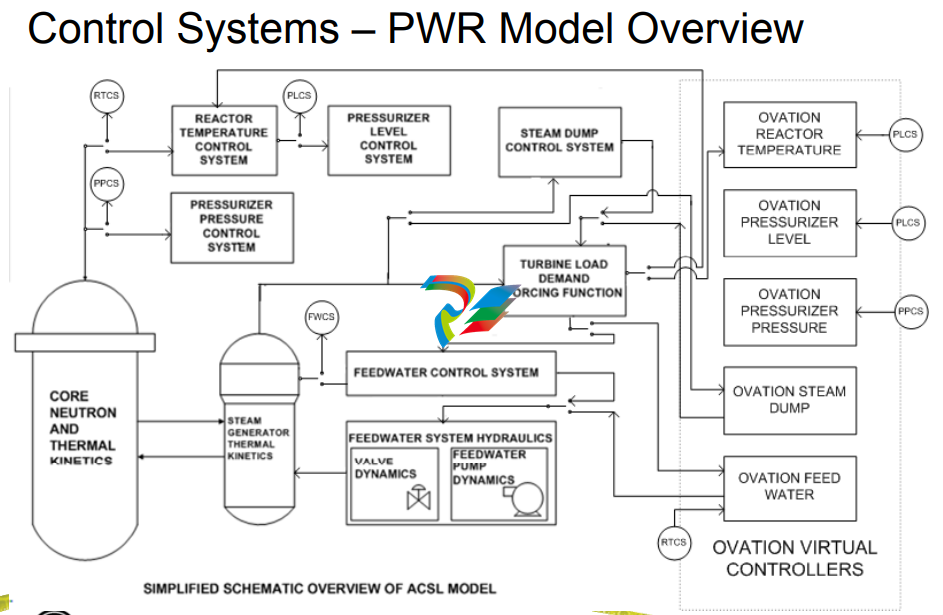

● Upon completion of setpoint analyses, the ACSL plantspecific control model is switched to Ovation virtual

controllers for real-time, closed-loop validation testing

● Verifies delivered system contains the proper setpoints and

control logic as presented in the functional requirement

documents

● Test performed by Subject Matter Expert along with detailed

checks of control logic tuning to verify that setpoints match

the intended design

Feed Water Application (SWIL) Feed Water Application (SWIL)

● Validation of plant dynamic performance using transient test

scenariE l os;

Examples:

– Ramp Load Increase from 1% Power to Turbine Synchronization Power Level at 1%/min

– Turbine Synchronization and Initial Load Pickup

– T bi T i With t R t T i ( t i t l l) Turbine

Trip Without Reactor

Trip (at appropriate power level)

– 100% Power ±10% Load Swing

– 100% Power Ramp Load Decrease to 15% Power at 5%/min (bringing on various pumps at the

appropriate power)

– 1 % 100% %/ ( ff 15

% Power Ramp Load Increase to 100% Power at 5%/min (taking off various pumps at the

appropriate power level)

– Large Load Rejection (dependent upon plant design typically either 50 or 100% capability)

– Loss of One Feedwater Pump

– Level Setpoint Step at 5% Power

– Level Setpoint Step at 100% Power

– Level Setpoint Step at 50% Power with One Feedwater Pump Operating

– Level Set

point Ste

p at 50% Power with Two Feedwater Pum

ps O

peratin

g.

Feed Water Application Software (SWIL) Feed Water Application Software (SWIL)

● Key Customer representatives participate in testing:

– Operations, systems engineering, training, etc.

● Results of the testing (trend plots, Control Builder mark-ups,

and logbook entries) are collected into a test report and

archived.

● Upon successful completion of this testing, the application

software is ready for loading into simulator and FAT on

target plant hardware.

Westinghouse Test Plan Overview Westinghouse Test Plan Overview

● Covers validation test approach.

● Each test phase builds upon previous testing in an Each test phase builds upon previous testing in an

overlapping, structured approach in the order listed below:

1. Initial Software Debug Tests

2. Testing of Application Software (includes dynamic SWIL tests)

3. Simulator Testing

4. FAT 1: Target Hardware (power up, controller/network FAT 1: Target Hardware (power up, controller/network

redundancy failover & I/O checkout)

5. FAT 2: Base System Hardware/software (network, OWS, EWS,

AVS Domain workstation and system security configurations AVS, Domain workstation and system security configurations

6. FAT 3: Including signal validation, graphics, hardware alarms

output redundancy and application hardware )

7 Site Testing site acceptance tests and po er ascension test