EMERSONWestinghouse Nuclear Automation

25

. Site Testing

– site acceptance tests and po

wer ascension test

Feed Water (FW) Control Systems Feed Water (FW) Control Systems

In delivering digital FW control systems,

W ti h li Westing

house applies:

• High Quality Application Software Development

Process

– Software Requirements Document

– Software Description Document

– S ft Lif l Pl S

oftware Lifecycle Plan

– Failure Modes and Affects Analysis (software and hardware)

– Software Hazards Analysis

– P i t t ith 10CFR50 A di B Processes consis

ten

t with 10CFR50

Appendix

B

where commercial grade application software can be

applied in critical applications

Feed Water (FW) Control Systems Feed Water (FW) Control Systems

Westinghouse NA uses “defense in design” to

ens re deli er of a high q alit prod ct ens

ure deli

very of

a high

q

uality prod

uct:

• Plant Specific Models and validation testing with application in closed

loop demonstrates deterministic behavior of the application early in

d i es gn process

• Applications are partitioned on controllers such as not to cause failures

that could add positive reactivity or effect plant design basis

• Reliance on the control network is limited Reliance on the control network is limited

– controllers and associated controllers and associated

I/O can continue to function with loss of network

• I/O designed on controller loss to revert to known or benign state

• For critical control component, a hard control station is provided to For critical control component,

a hard control station is provided to

operator manual control – another layer of redundancy

• Redundancy of system components at all levels

Existing Analog Feed Water Control Existing Analog Feed Water Control

● Historically, Steam Generator Water Level has

been difficult to contro

l

– Analog-based systems are limited

– Per INPO data; second leading system for plant trip

– Steam Generator (SG) shrink and swell phenomena

– Steam & Steam

& feedwater feedwater measurement unreliable at low power levels measurement unreliable at low power levels

– Manual control with multiple operators required to bring up unit

– Prone to single points of failure

Analog Inputs – no active redundancy

Manual operator action in detecting input failures

Modulating Outputs single driver card

29

Modulating Outputs

– single driver card

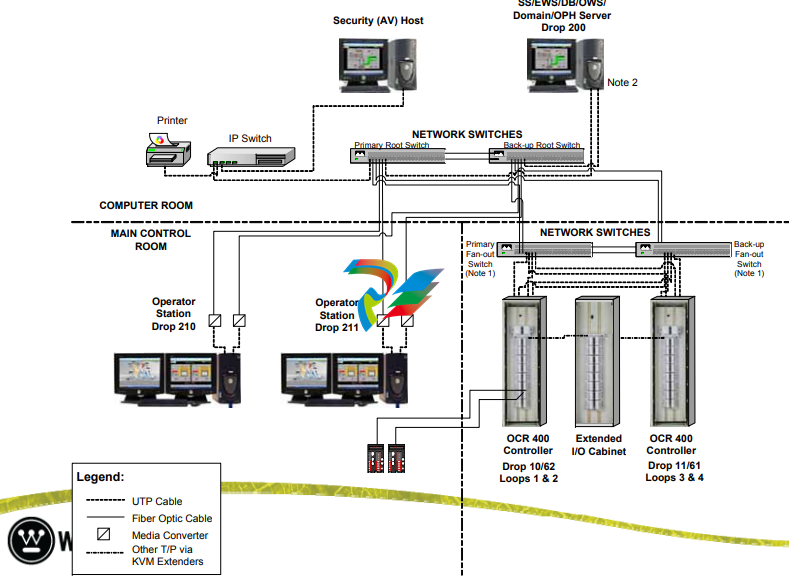

Typical Advanced Digital Feed Water

System (ADFCS) Configuration System (ADFCS) Configuration

● 1,2, 3 or 4 Redundant Controllers:

● HMI -T O t W k t ti ith ft t l Two

Opera

tor

Wor

k

s

t

ations with soft con

trols

– M/A Stations for FW Valve & FP Controls

● One Engineer One Engineer s/Data ’s/Data Base Server Workstation Base Server Workstation

● Network Equipment – Fast Ethernet Switches

● Anti-virus Station

● New Cabinets or retrofit of existing cabinets

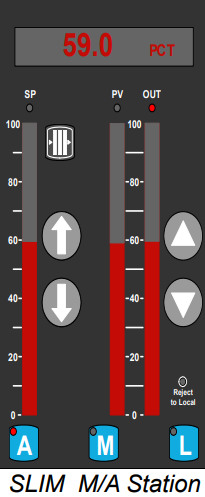

● SLIM M/A’s for Main, Bypass and Feed Pumps

ADFCS

– Main Control Room Main Control Room

● Redundant operator stations & LCD

displays in MCR displays in MCR 59 0 PCT

● SLIM M/A’s for all modulating valves, &

feed pumps

Add d l f d d

59.0 PCT

100

SP PV OUT

100

Add

e

d layer o

f re

dun

dancy upon

controller failure

Works seamlessly with soft control

80

60 60

80

● Remove signal selector switches

● Remove select recorders – steam/feed

water, wide and narrow ran

ge level 20

40

20

40

, g

● Remove individual channel indicators &

replace with median

● Select indicators can remain

“live

”

Typical ADFCS Architecture Typical ADFCS Architecture

ADFCS

– Design Overview Design Overview

● Improved system reliability via signal selectors

– Narrow Range Level

– Wide Range Level

– Feedwater Flow

– Steam Flow

– Steam Pressure

– Feedwater Tem

perature

– Turbine Impulse Pressure or Nuclear Power

– Feedwater Header Pressure

( ) FP turbine runback)

● Improve System performance by integrating feed pump governor controls

ADFCS

– Design Overview Design Overview

● Proven Control Application – third generation

design consistent with AP1000 design consistent with AP1000

– Low and High Power Controllers

Bumpless Transfer between Low Power and High

P C t lM d Power

Con

tro

l

M

o

de

– Feedwater Temperature Compensation

Low Power Level Controller gain & reset adjusted Low Power Level Controller gain

& reset adjusted

based on feedwater temperature

Compensates for the effects of shrink and swell in

ll t eve

l response

to fd t ee

dwa

ter fl i ti flow variations

– High Power Level Controller proportional gain and

integral time adjusted based on steam flow

35

integral time adjusted based on steam flow

ADFCS

– Design Overview Design Overview

● Proven Control Application (cont’d)

– Load Index Load Index

Wide Range Level

Anticipates need for flow change at low power

– Automatic transition from bypass valve to main feed Automatic transition from bypass valve to main feed water regulation valve

– Capability of operating with one valve in manual and other in auto other in auto

– Control Valve Linearization & Performance

Compensates for non-linearities in valve characteristics and ensures an effective and stable

control response

Position feedback provides means to detect sticking or sluggish valve response and alert the operator