ABBProduct specification

Overview of this specification About this product specification It describes the performance of the manipulator oracomplete family of manipulators in terms of:

• The structure and dimensional prints

• The fulfilment of standards, safety and operating requirements

• The load diagrams, mounting of extra equipment, the motion and the robot reach

• The specification of variants and options available

Usage Product specifications are used to find data and performance about the product, for example to decide which product to buy. How to handle the product is described in the product manual.

Users It is intended for:

• Product managers and product personnel

• Sales and marketing personnel

• Order and customer service personnel

1 Description

1.1 Structure

1.1.1 Introduction to structure

General

The IRB 1200 is one of ABB Robotics latest generation of 6-axis industrial robot, with a payload of 5 to 7 kg, designed specifically for manufacturing industries that use flexible robot-based automation, e.g. 3C industry. The robot has an open structure that is especially adapted for flexible use, and can communicate extensively with external systems

Type A of IRB

1200 Type A - Axis Calibration

The difference between IRB 1200 and IRB 1200 Type A is that the Type A is calibrated with Axis Calibration. On each axis there are bushings for installation of calibration tools. As a result of this, the castings differ between IRB 1200 and IRB 1200 Type A

Note IRB 1200 Type B is designed based on IRB 1200 Type A so that Type B has the bushings for installation of calibration tools too. The difference between IRB 1200 Type A and IRB 1200 Type B is that Type B also supports SafeMove 2. See Type B of IRB 1200 on page 9. How to know which type the robot is? The type label on the base of the robot tells if the robot is calibrated with Axis Calibration. Those robots are named IRB 1200 Type A.

1.1.1 Introduction to structure Continued

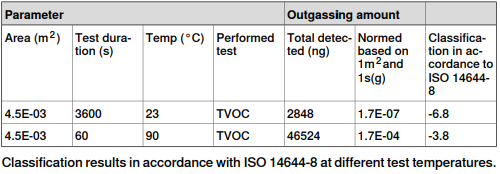

Particle emission from the robot fulfill Clean room class 3 standard according to DIN EN ISO 14644-1. Clean room robots are specially designed to work in a clean room environment. According to IPA test result, the robot IRB 1200 is suitable for use in clean room environments. Clean room robots are designed in order to prevent from particle emission from the robot. For example is, frequent maintenance work possible to perform without cracking the paint. The robot is painted with four layers of polyurethane paint. The last layer being a varnish over labels in order to simplify cleaning. The paint has been tested regarding outgassing of Volatile Organic Compounds (VOC) and been classified in accordance with ISO 14644-8. Classification of airborne molecular contamination, see below:

Food grade lubrication The robot has food grade lubrication (NSF H1) as an option (777-1). The protection type for robots with food grade lubrication is Clean Room and IP67.

IP67/66 protection The robot has IP67 as an option. The option will add sealing, machining parts and gasket.

Protection type Foundry Plus 2 Robots with the option Foundry Plus 2 are designed for harsh environments where the robot is exposed to sprays of coolants, lubricants and metal spits that are typical for die casting applications or other similar applications. Typical applications are spraying insertion and part extraction of die-casting machines, handling in sand casting and gravity casting, etc. (Please refer to Foundry Prime robots for washing applications or other similar applications). Special care must be taken in regard to operational and maintenance requirements for applications in foundry are as well as in other applications areas. Please contact ABB Robotics Sales organization if in doubt regarding specificapplication feasibility for the Foundry Plus 2 protected robot. The robot is painted with two-component epoxy on top of a primer for corrosion protection. To further improve the corrosion protection additional rust preventive are applied to exposed and crucial areas, e.g. has the tool flange a special preventive coating. Although, continuous splashing of water or other similar rust formation fluids may cause rust attach on the robots unpainted areas, joints, or other unprotected surfaces. Under these circumstances it is recommended to add rust inhibitor to the fluid or take other measures to prevent potential rust formation on the mentioned. The entire robot is IP67 compliant according to IEC 60529 - from base to wrist, which means that the electrical compartments are sealed against water and solid contaminants. Among other things all sensitive parts are better protected than the standard offer. Selected Foundry Plus 2 features: • Improved sealing to prevent penetration into cavities to secure IP67 • Additional protection of cabling and electronics • Special covers that protect cavities • Well-proven connectors • Black chrome coated tool flange • Rust preventives on screws, washers and unpainted/machined surfaces • Extended service and maintenance program The Foundry Plus 2 robot can be cleaned with appropriate washing equipment according to the robot product manual. Appropriate cleaning and maintenance is required to maintain the protection, for example can rust preventive be washed off with wrong cleaning method. Available robot versions The option Foundry Plus 2 might not be available for all robot versions. See Specification of variants and options on page 53 for robot versions and other options not selectable together with Foundry Plus 2.