ABBProduct specification

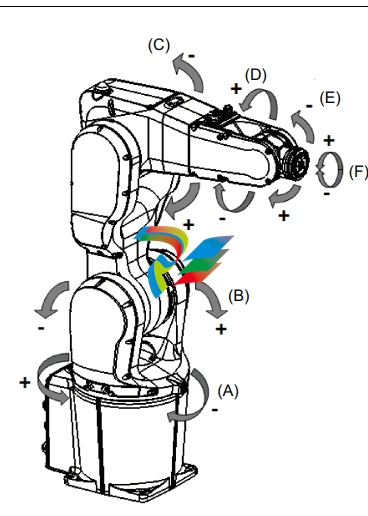

perating system The robot is equipped with the IRC5 Compact (IRC5C) or IRC5 (Single cabinet) controller and robot control software, RobotWare. RobotWare supports every aspect of the robot system, such as motion control, development and execution of application programs, communication etc. See Product specification - Controller IRC5 with FlexPendant (IRC5C included). Safety The safety standards are valid for the complete robot, manipulator and controller. Additional functionality For additional functionality, the robot can be equipped with optional software for application support - for example gluing and welding, communication features - network communication - and advanced functions such as multitasking, sensor control etc. For a complete description on optional software, see Product specification - Controller software IRC5. Manipulator axes (A) (D) (E) (F) (C) (B) xx1300000365 Continues on next page 12 Product specification - IRB 1200 3HAC046982-001 Revision: K © Copyright 2019 ABB. All rights reserved. 1 Description 1

1.3 Installation 1.3.1 Introduction to installation General IRB 1200 is adapted for normal industrial environment. Depending on robot variant, an end effector with max. weight of 5 or 7 kg, including payload, can be mounted on the robot’s mounting flange (axis 6). Other equipment, weighing a maximum of 0.3 kg, can be mounted on the upper arm. For more information about mounting of extra equipment, see Fitting of equipment on page 32

1.4.1 Introduction to load diagram1.4 Load diagram 1.4.1 Introduction to load diagram Information WARNING It is very important to always define correct actual load data and correct payload of the robot. Incorrect definitions of load data can result in overloading of the robot. If incorrect load data and/or loads are outside load diagram is used the following parts can be damaged due to overload: • motors • gearboxes • mechanical structure WARNING In the robot system is the service routine LoadIdentify available, which allows the user to make an automatic definition of the tool and load, to determine correct load parameters. For detailed information, see Operating manual - IRC5 with FlexPendant. WARNING Robots running with incorrect load data and/or with loads outside diagram, will not be covered by robot warranty. General The load diagram includes a nominal pay load inertia, J0 of 0.06 kgm2 and an extra load of 0.3 kg at the upper arm housing. At different moment of inertia the load diagram will be changed. For robots thatare allowed tilted, wall or inverted mounted, the load diagrams as given are valid and thus it is also possible to use RobotLoad within those tilt and axis limits. Control of load case by "RobotLoad" To easily controla specific load case, use the calculation program ABB RobotLoad. Contact your local ABB organization for more information. The result from RobotLoad is only valid within the maximum loads and tilt angles. There is no warning if the maximum permitted armload is exceeded. For over load cases and special applications, contact ABB for further analysis.

1.6.3 Absolute Accuracy calibration Continued

When is Absolute Accuracy being used Absolute Accuracy works on a robot target in Cartesian coordinates, not on the individual joints. Therefore, joint based movements (e.g. MoveAbsJ) will not be affected. If the robot is inverted, the Absolute Accuracy calibration must be performed when the robot is inverted. Absolute Accuracy active Absolute Accuracy will be active in the following cases:

• Any motion function based on robtargets (e.g. MoveL) and ModPos on robtargets • Reorientation jogging • Linear jogging

• Tool definition (4, 5, 6 point tool definition, room fixed TCP, stationary tool)

• Work object definition Absolute Accuracy not active The following are examples of when Absolute Accuracy is not active:

• Any motion function based on a jointtarget (MoveAbsJ)

• Independent joint

• Joint based jogging

• Additional axes

• Track motion Note In a robot system with, for example, an additional axis or track motion, the Absolute Accuracy is active for the manipulator but not for the additional axis or track motion. RAPID instructions There are no RAPID instructions included in this option. MultiMove If the main robot in a MultiMove system has the Absolute Accuracy option, it opens up Absolute Accuracy capability for all the robots in the system. However, each robot needs to be calibrated individually. Note Note that this is the only RobotWare option that is relevant for an additional robot.

1.7 Maintenance and troubleshooting 1.7.1 Introduction to maintenance and trouble shooting General The robot requires only a minimum of maintenance during operation. It has been designed to make it as easy to service as possible:

• Maintenance-free AC motors are used.

• Grease used for all gearboxes.

• The cabling is routed for longevity, and in the unlikely event of a failure, its modular design makes it easy to change. Maintenance The maintenance intervals depend on the use of the robot, the required maintenance activitiesalso depends on selected options. For detailed information on maintenance procedures, see Maintenance section in the Product Manual - IRB 1200.