ABB Procontic CS 31 Intelligent decentralized automation system

This technical documentation supplied in a loose-leaf file can be easily up-dated.

In order to be registered in our revision and up-dating service, the enclosed Original Registration Form(1) should be

filled-in and addressed to your local ABB contact engineer.

The supplements contain either new sections of the documentation or replacement pages for existing sections.

Instructions for these supplements are enclosed in the corresponding parcel.

All rights reserved to change design, size, weight of the equipment described in our documentation.

Dear Sirs,

I want to keep my technical documentation updated, which is why I would like to

have my name to your list for distribution of revised documentation. The returned

original reply card contains all relevant information.

I am interested in detailled information about modifications on existing devices as

well as technical details of novel devices forming part of the control system used in

my installation.

ABB CS31

Intelligent decentralized

automation system

General

Machines and plant equipment, for

reasons of competitiveness are becoming even more

complex, the amount of information required from sensors

and actuating devices is constantly expanding, causing

heavier implementation and higher wiring costs.

The ABB Procontic CS 31 is designed to simplify

implementation and wiring.

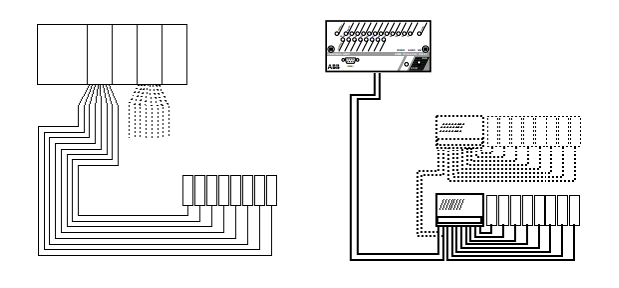

The CS 31 is a decentralized automation system.

The system is ideally suited to applications where

modularity and cost reduction are key factors.

The CS 31 system comprises of the following :

– a central unit, enclosed within a compact case which

can be screw or DIN rail mounted,

– remote input/output plug-in units, wich are easily

removeable. The plug-in base can be screw or DIN

rail mounted,

– a simple twisted pair wire arrangement (RS 485),

which is utilized for connection of the central unit to

the I/O units.

The decentralized architecture of the ABB

Procontic CS 31 system offers a superior solution to

control system requirements:

– The central unit can be mounted within the control

panel.

– The input/output units can be mounted local to the

sensors and actuators.

As an example the central unit may be connected to

remote units distributed along a process line.

A cost reduction in wiring is possible upto 80% with the

implementation of the CS 31 system.

2.1 CS 31 benefits

– decentralized architecture as opposed to centralized

system,

– reduction of wiring costs (design, materials and

commissioning time),

– configurable input/output units,

– extensive diagnosis functions,

– freely expandable network. Additional units can be

connected whilst the installation is operational,

– simple transparent programming. All remote I/O channels

are handled as though they were centralized,

– remote I/O facility is integral feature and not an additional

unit,

– programmable serial communications (RS 232)

connection to modem, printer, operator display etc...

2.2 Modular system

The comprehensive range of units enhances the modularity

of the system.

For example :

The low profile 16 channel user configurable input/output

unit can be mounted on the control panel door, with inputs

and outputs connected to pushbuttons and pilot lamps.

2.3 Versatile range

The CS 31 is based upon two types of central units,

07 KR 91, 07 KT 92/07 KT 93 and 07 KR 31/07 KT 31.

The system can be configured to comply with most control

system requirements (See previous configuration

examples).

● 07 KR 91, 07 KT 92/07 KT 93 is designed for complex

applications with an higher level of functionality (Data

manipulation, PID regulation, etc...).

● 07 KR 31/07 KT 31 incorporates all of the functions

required for smaller decentralized applications, thus

providing an excellent Price/Performance ratio.

2.4 Diagnosis

The CS 31 system incorporates extensive diagnosis

functions.

All of the remote units contain a microprocessor which is

dedicated to the management of inputs/outputs and

diagnosis facilities.

The diagnosis are accessed using the "test" button on the

front of each remote unit, the results are displayed on the

I/O status led's.

The diagnosis results can be incorporated with the user

program thus enabling effective fault management.

2.5 Use of the CS 31 system

All of the remote units are easily interchangeable, even

with the process in operation, as they are plug-in base

mounted.

The screw terminals of the plug-in bases are used for

connection to the process inputs and outputs.

Bases are screw or DIN rail mounted.

The DIL switches on the bases are used for coding the

address of units.

Any additional connected units are automatically

recognized by the central unit.

NOTE : The system may comprise of remote units of

varying supply and input voltages.

2.6 Emergency operation

A system may comprise of many central units, however

one single master and the remainders slaves.

If the bus communication is interrupted or the master unit

fails the individual slave units continue with their own

operation.

2.8 General characteristics

The CS 31 system is developped according to the international standard IEC 1131-2.

● Operating conditions

– Temperature :

● operation 0 °C ... + 55 °C 32 ... 131 °F

● storage - 40 °C ... + 75 °C - 40 ... 167 °F

● transport - 25 °C ... + 75 °C - 13 ... 167 °F