Moog G122-829A001 P-I Servoamplifier: Technical Summary

Moog G122-829A001 P-I 伺服放大器:技术摘要

介绍和范围

本文档总结了 Moog G122-829A001 的技术细节,这是一款通用的、用户可配置的 P-I(比例积分)伺服放大器。它专为各种闭环控制应用而设计,可通过内部开关和外部电位计灵活地进行调整。本摘要基于 G122-829A001 应用说明。

核心功能

G122-829A001 是一款单通道伺服放大器,可配置为在多种控制模式下运行:

Proportional (P) control: The output is proportional to the error signal.

Integral (I) control: The output integrates the error signal over time to eliminate steady-state error.

Proportional + Integral (P-I) control: Combines both P and I actions for robust control.

The selection between these modes and other operational characteristics is managed by internal DIP switches and adjustable potentiometers, making it a versatile solution for many different systems.

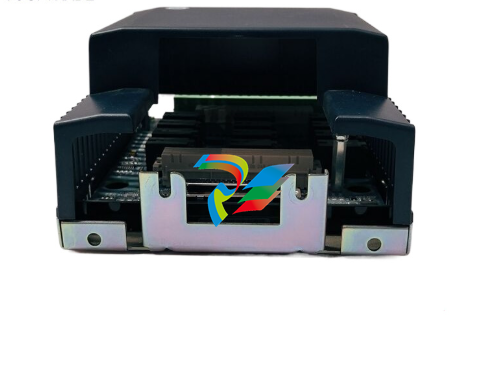

Physical & Installation Specifications

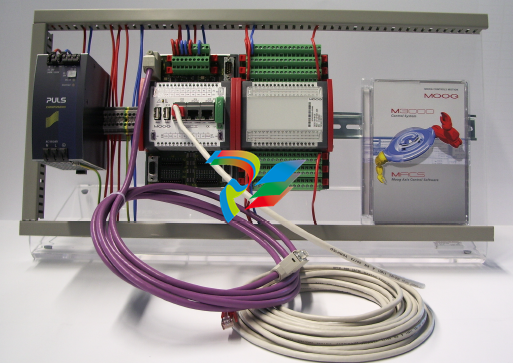

Mounting: Designed for horizontal mounting on a standard DIN rail within a suitable industrial steel enclosure.

Cooling: The case features top and bottom vents for passive cooling via airflow. These vents must be kept clear.

Wiring: Screw terminals accommodate wire sizes from 0.2mm² to 2.5mm² (24AWG to 12AWG). The use of shielded cables is recommended for all connections to ensure EMC compliance.

Power Supply: Requires a nominal 24V DC supply (range: 22V to 28V).

Inputs Configuration

The amplifier features multiple inputs that are summed at the error amplifier stage.

Feedback Input: This is the primary input for the feedback transducer signal. It is a differential input, configurable for either 4-20mA or ±10V signals. It includes front-panel-accessible potentiometers for gain and zero adjustments, making it ideal for scaling various feedback signals.

Input 1: A non-inverting ±10V input with a scale potentiometer (adjustable from 10% to 100%) and a switch-selectable 55ms input lag. It is well-suited for use as the primary command signal.

Input 2: A differential input that is switch-selectable between 4-20mA and ±10V. It can be used for either command or feedback signals.

Input 3: A direct input to the output summing amplifier, typically used for command feed-forward or for closing an outer loop in a multi-stage valve system.

Output Configuration

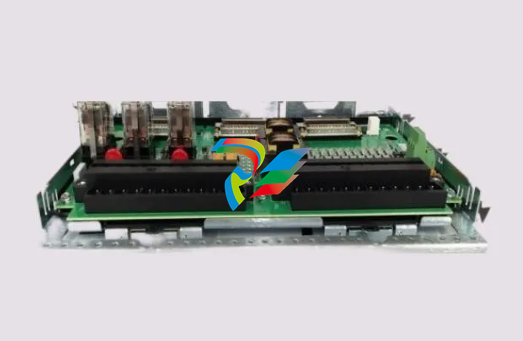

The amplifier's output is highly configurable to drive a wide range of proportional valves.

Valve Drive Output: Switch-selectable output type:

Voltage: ±10V into a minimum load of 200 Ohm.

Current: Selectable from ±5mA up to ±100mA, configured via a set of summing DIP switches.

4-20mA: A specific current output mode for standard industrial actuators.

Dither: A fixed 200 Hz dither signal can be enabled. Its amplitude is adjustable via a front-panel potentiometer up to ±10% of the selected valve drive.

"In Position" Signal: Provides an opto-isolated current path when the valve drive signal falls below a ±10% threshold, useful for signaling a PLC to proceed with the next step in a sequence.

Adjustments and Setup

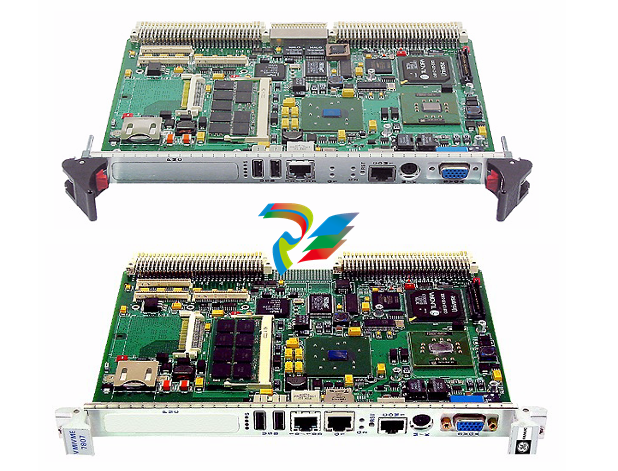

Onboard Switches (SW1-SW7): Internal DIP switches are used to configure key operational parameters such as output type (voltage/current), integrator input source (from error amp or P-stage), I-limit, dither enable, and feedback configuration.

Front Panel Potentiometers: Multi-turn potentiometers provide fine adjustment for:

Proportional Gain (P gain)

Integral Gain (I gain)

Input 1 Scale

Error Amp Bias

Dither Level

Step Push Button (SW3): A built-in diagnostic tool that injects a -50% step disturbance into the valve drive signal. This is used for system identification and for tuning the P and I gains to achieve optimal closed-loop performance.

Enable Input: A 24V DC enable input energizes an internal relay that connects the output stage to the terminals and un-clamps the integrator. This can be permanently enabled via an internal switch for continuous operation.

.jpg)