EMERSONTest Platform for Automation System

gets an input from the pressure transmitter.

The Operator Interface

The tool for creating an operator interface is object based. It contains images of valves,

engines, fire etc. The objects can be animated which makes it possible to create an

operator environment in which the operator can easily get an impression of the state of

the process.

1.3 Report Outline

This report is arranged as follows:

Chapter 2 - The platform and the course material presents how the hardware as well as

the software for the test platform have been developed.

Chapter 3 - Results presents the result, i.e. the finished test platform.

Chapter 4 - Conclusions presents the conclusions of this project. The chapter also

presents a few suggestions on how the test platform can be improved.

Chapter 2

The platform and the course material

The following chapter will present the platform and the system design; firstly the devices

that are present and how the physical process works and secondly the course material.

2.1 The system design

When choosing the system design the requirements presented in Section 1.2.4 were

first

and foremost taken into account. When considering the purpose of the test platform an

addition was made to the requirements:

• To make a process that is easy to understand, but that is adequately advanced

for using advanced control tools in DeltaV.

With these requirements a system design was developed. The principle of the process is

briefly described below. Figure 2.1 illustrates of the principle of the process.

A pressure tank with a needle valve is filled half way up with water. When the control

system starts, air flows into a tank through a mass flow controller and the pressure in the

tank is controlled to stabilize around ~1500 mbar.

When the pressure has been held around 1500 mbar for a specified time a pneumatic

valve will open and tap out water into an open tank that is placed below the pressure

tank. The valve will stay open until a level sensor indicates that the tank is full.

When the open tank is full a heating plate will start to heat up the water. The

temperature is controlled with on/off controlling to ~35 ºC.

To continue the process the open tank has to be removed, emptied and put back in

place. This will restart the process. This can be repeated until the pressure tank is

empty.

• Buttons

The button device consists of one red button with red light and one green button

with green light. The buttons can also be lit.

Devices connected to Foundation Fieldbus

• Pressure transmitter

A pressure transmitter measures and transmits the pressure value.

• Temperature transmitter

A temperature transmitter measures and transmits the temperature.

Devices connected to Profibus

• Mass Flow Controller

A mass flow controller controls the inflow of gas from one place to another.

Devices connected to Discrete Out

• Relays

A relay is a device that can control other devices with on and off.

Devices connected to relays

Light bulb

Heat plate

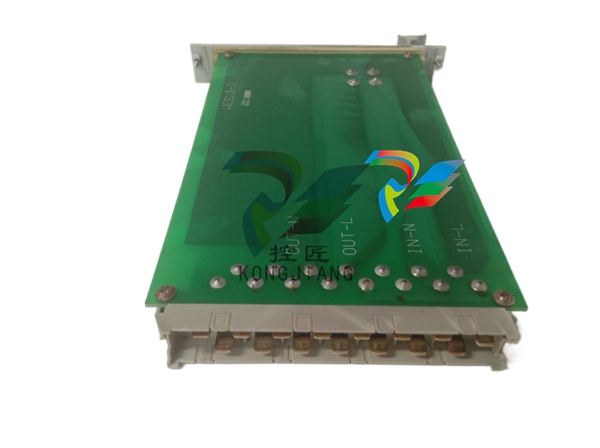

• Valve Island

A Valve Island is a device with several electrically controlled valves. The valves

are normally closed, but they open when they receive a signal from the controller.

Devices connected to Discrete In

• Capacitive Proximity Sensor (Level Transmitter)

A capacitive proximity sensor is used for detecting objects that are proximal to the

sensor.

Other objects in the test platform

• Pressure tank

A pressure tank was constructed for the test platform. It is designed to be able to

handle a pressure of 10 bar and to contain both water and air. It has four

connections; one that can be connected to the mass flow controller, one that can

be connected to the pressure transmitter, one that can be connected to the

needle valve and one that can be connected to a pneumatic valve. It also has one

inflow so that it can be filled with water.

• Open tank

The open tank is a much less advanced tank than the pressure tank. It is open

and therefore it must not be able to handle any pressure and it does not have any

connections. It is metallic so that it can be detected by an inductive proximity

sensor.

• Pneumatic Valve

A pneumatic valve is normally closed, but opens if it is exposed to pressurized air.

• Compressor / Pressurized air media

Depending on where the platform is used a compressor or pressurized air media

is used. A compressor is used when there is no pressurized air media available.

Since a compressor has a high sound level and in addition is heavy to carry it is

only meant to be used when there is no other option.

Detailed description of the Physical Process

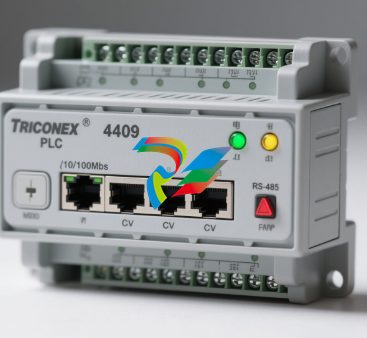

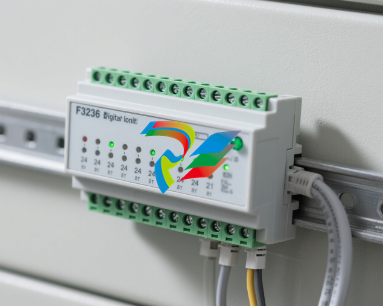

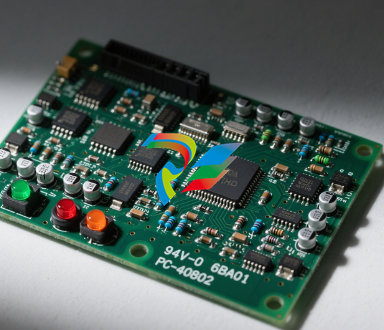

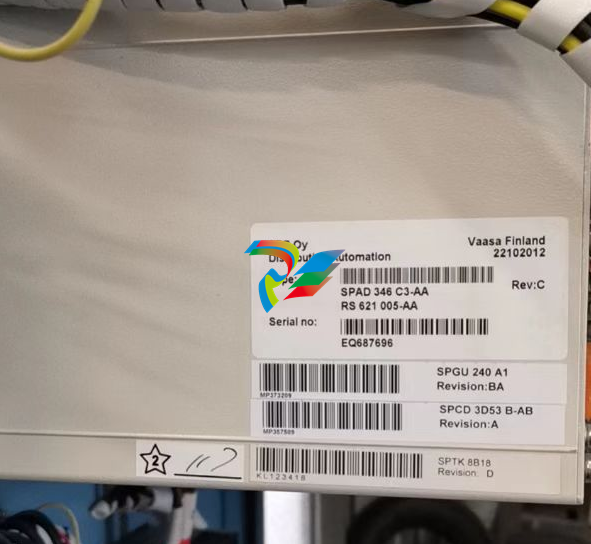

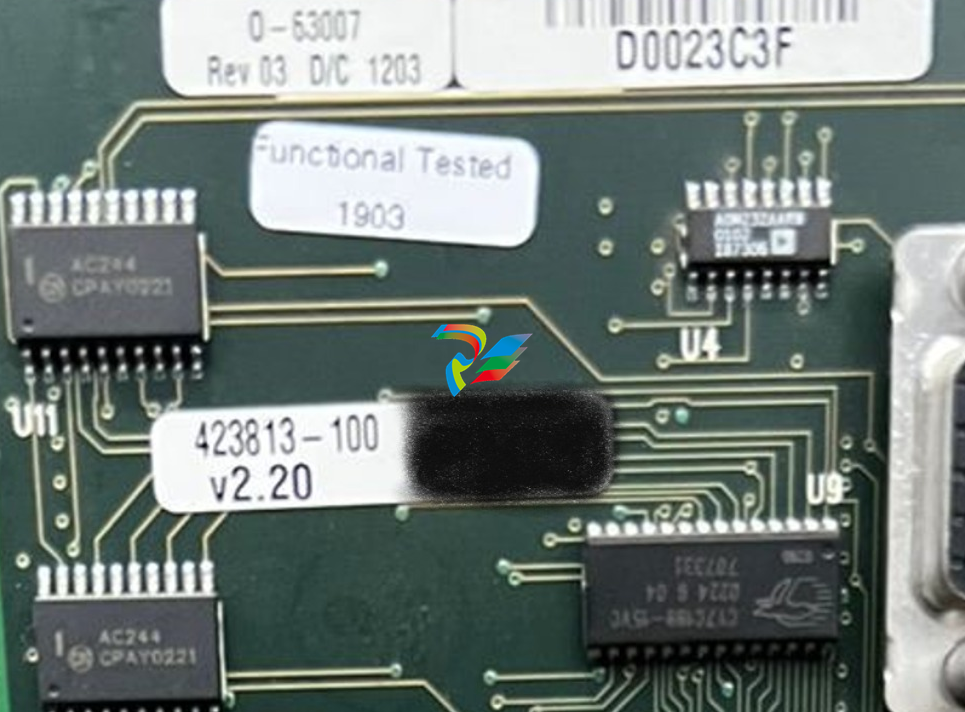

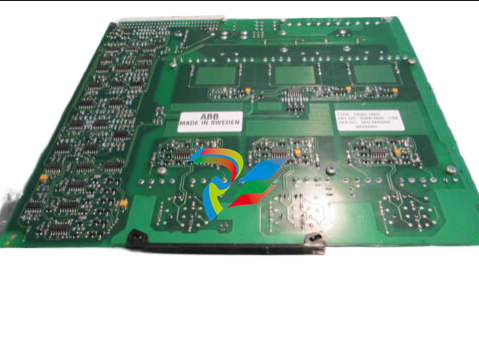

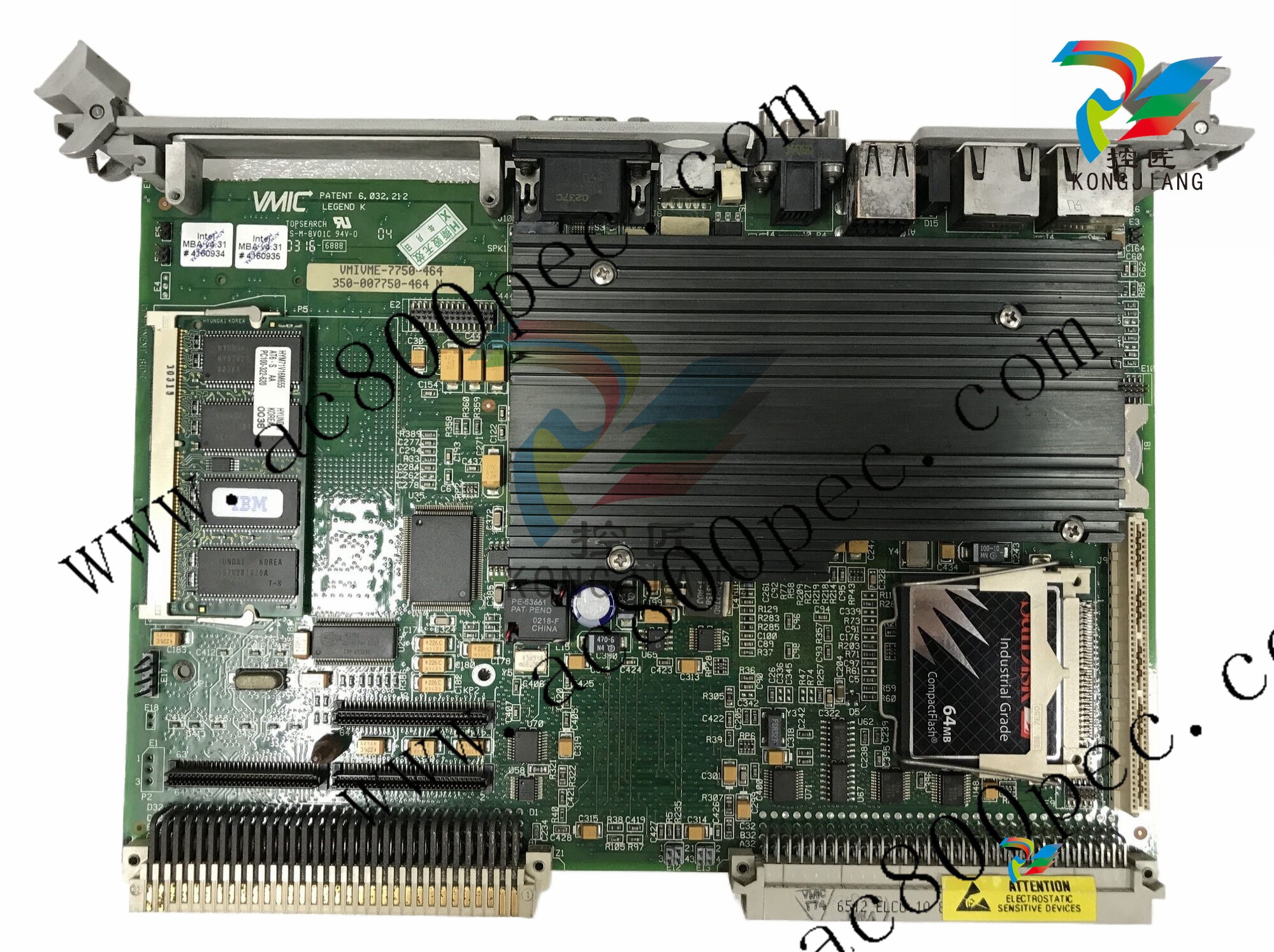

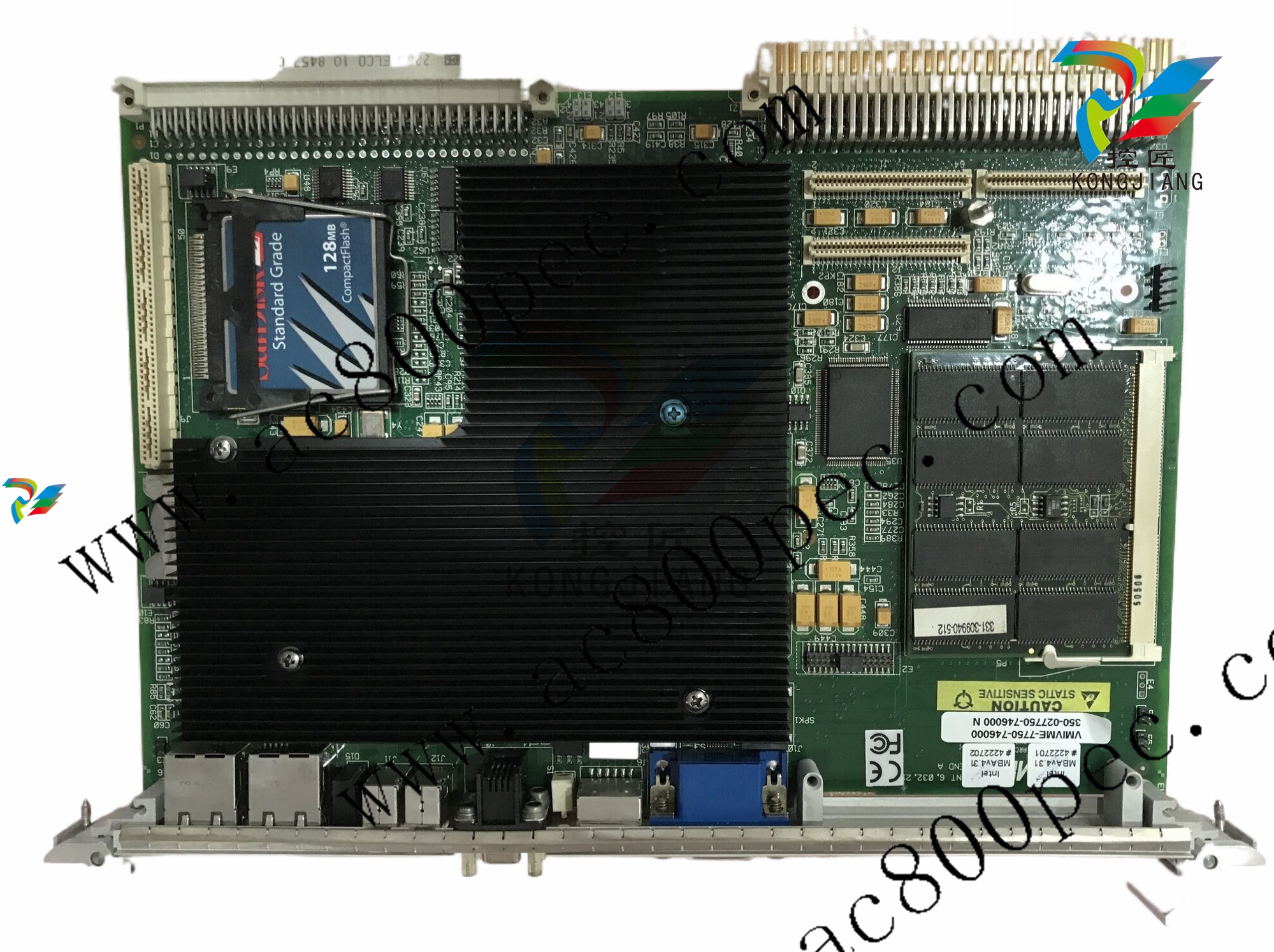

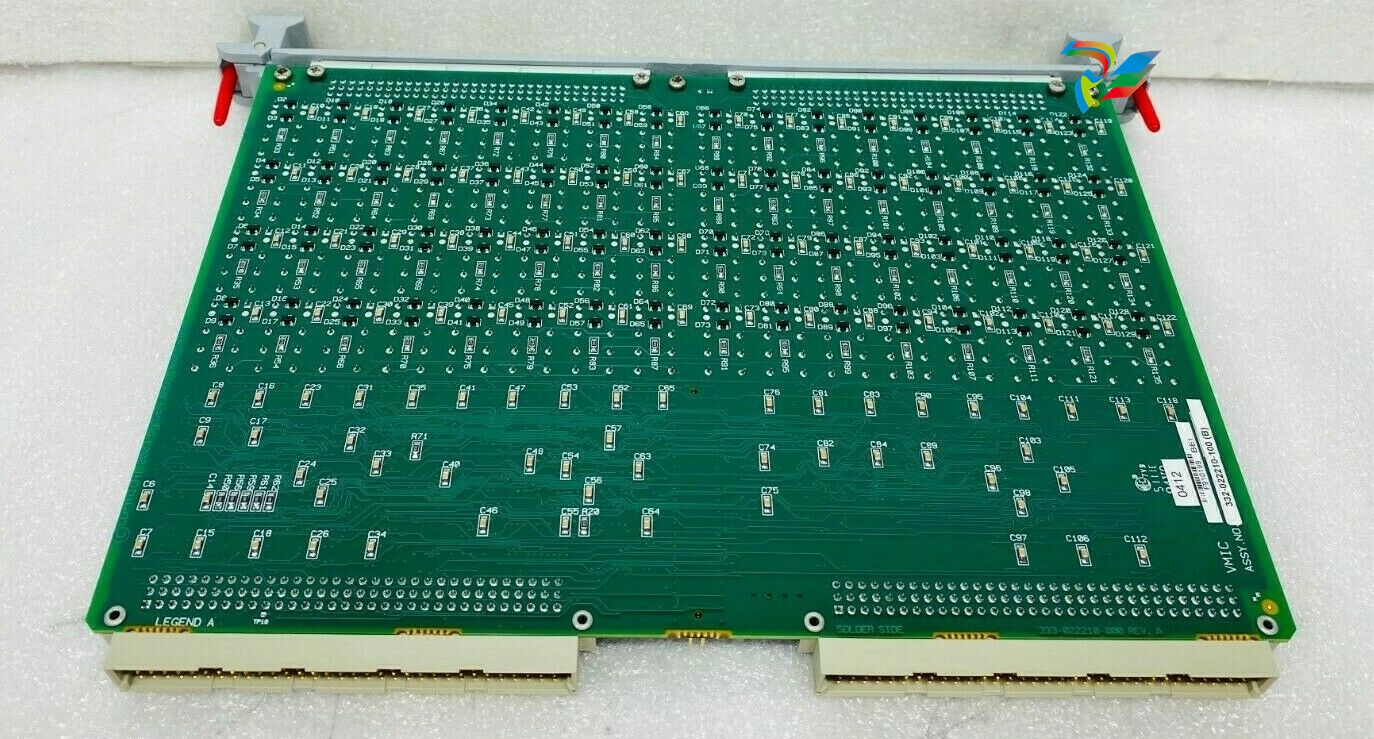

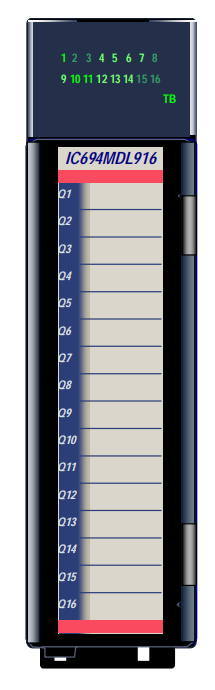

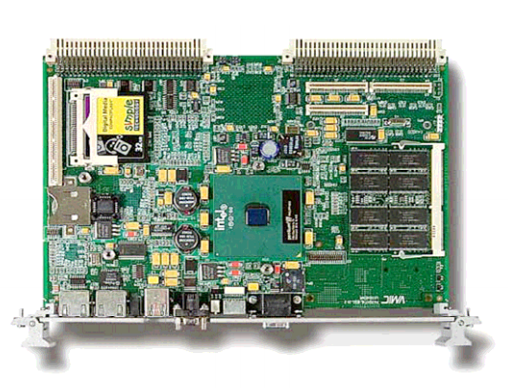

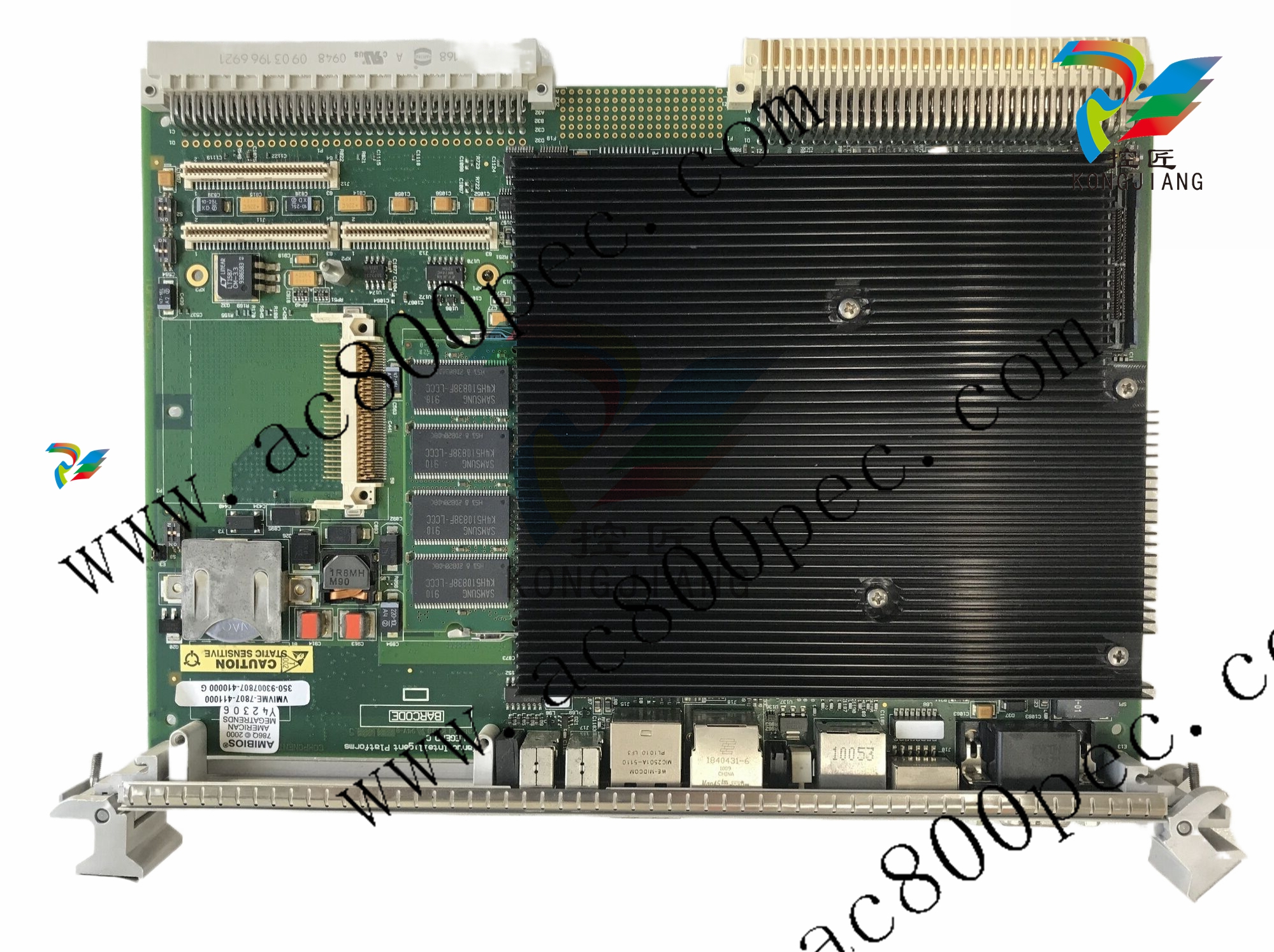

1. DeltaV controller, I/O and

fieldbus cards

2. Pressure transmitter

3. Mass Flow Controller

4. Valve island

5. Inductive Proximity Sensor

6. Capacitive Proximity Sensor