EMERSONTest Platform for Automation System

with DeltaV; relays, fuses, pressure transmitter, proximity sensors etc. Naturally, the

hardware should also include the automation system, DeltaV. The platform should be

small enough to be portable.

The requirement on the software part was similarly that it should at least include some

similar algorithms as the software for the real production processes includes. It was also

required that the software should include an operator interface in which an operator can

get the relevant information about the process; alarms indicating that something is

wrong, diagrams, an illustration of the process where the operator can follow what

happens etc.

The requirement on the course compendium was that a person who reads it should be

able to replicate the control software that was developed in this project. Persons taking

the course will have the original software as a key, which they should only use if they

experience significant problems.

Hence, to meet all requirement from Sandvik Coromant, the finished platform and

additional educational material should include the following:

• The DeltaV System with controller cards, I/O cards and fieldbus cards.

• Devices that are more or less the same as in the production processes at

Sandvik Coromant where DeltaV is used, for instance proximity sensors or

pressure transmitters.

• A software control system containing similar algorithms as the production

processes at Sandvik Coromant, for instance it might be of great relevance to

use a PID controller.

• An operator interface illustration that follows the physical process. The operator

environment should also contain an alarm list.

• A course compendium with both general information about functions in DeltaV

and instructions on how to create the same control system as the one which was

developed in this project.

1.1.5 Aim

The aim of this project was to make a test platform along with a course compendium.

The test platform should be portable so that it can be brought to people for education in

DeltaV regardless of where the persons are stationed. This education should give a

general knowledge on how to use DeltaV and after completing this course the engineers

should be able to implement simple control systems.

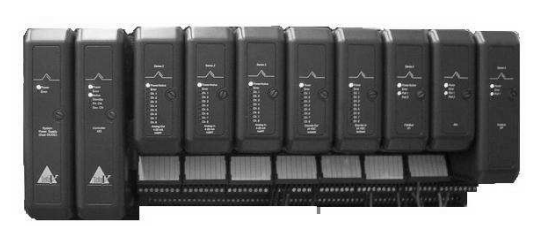

1.2 DeltaV-a DCS automation system

In industry there are different automation systems; some that are more basic and some

that are more advanced. This section will give an introduction to automation systems in

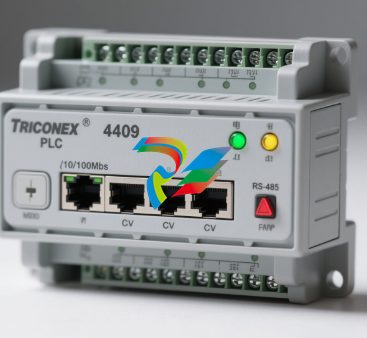

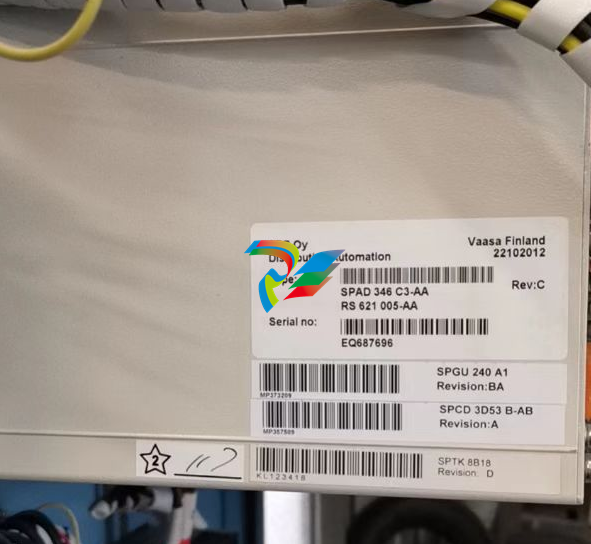

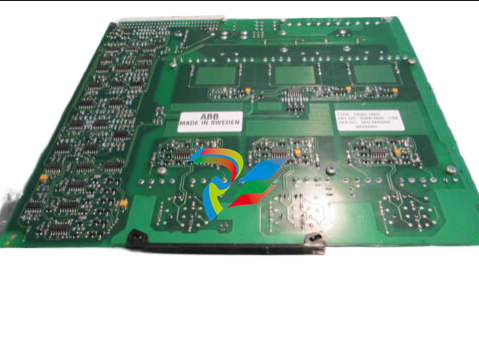

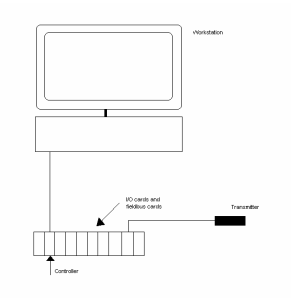

general and the specific automation system, DeltaV, that this project concerns. Figure

1.1 shows the hardware of the DeltaV automation system.

DeltaV is a DCS automation system. DCS is short for Distributed Control System and it

is and automation system that has evolved from PLC.[1]

PLC is short for Programmable Logic Controller. Originally PLC systems replaced old

automation systems that included many relays. PLC systems did then include only

discrete signals and when DCS was new, the difference between the two automation

systems was that DCS also included analog signals. However, today PLC includes both

analog and discrete signals and the difference between PLC and DCS is vague. Newer

designs look similar both in hardware and in software.[2]

The DeltaV automation system consists of one hardware part and one software part. In

the following subsections both parts willl be explained.

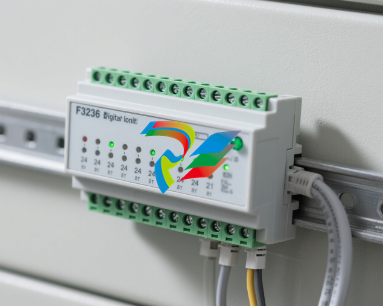

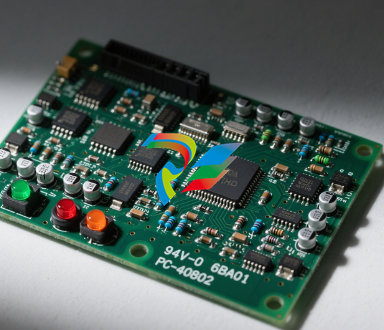

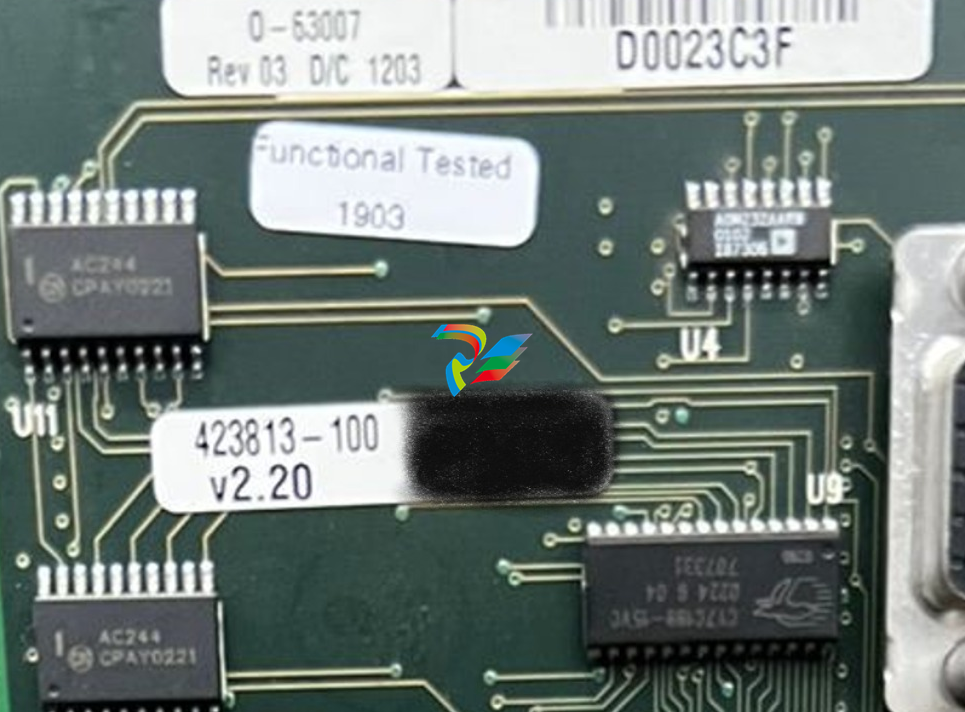

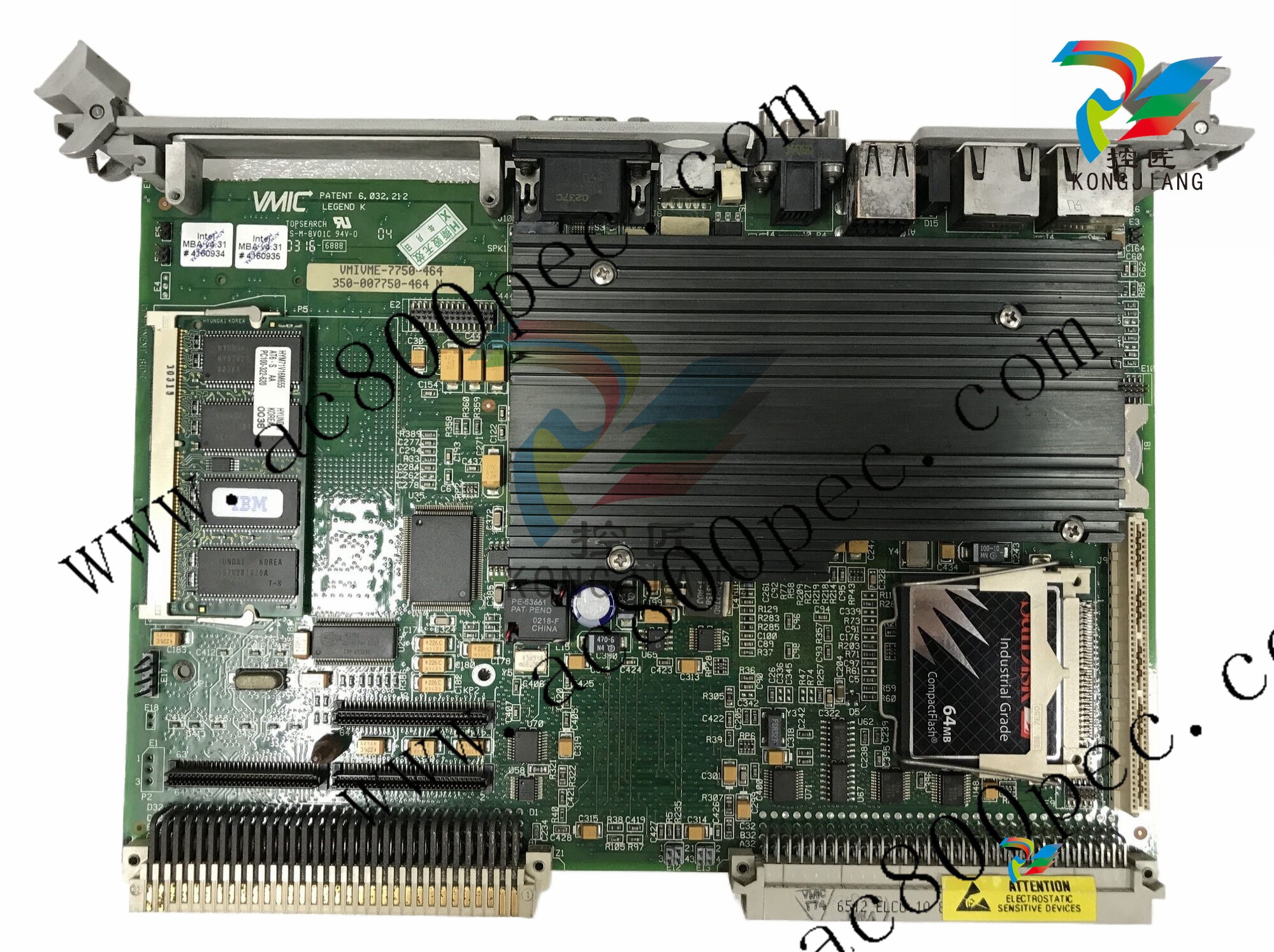

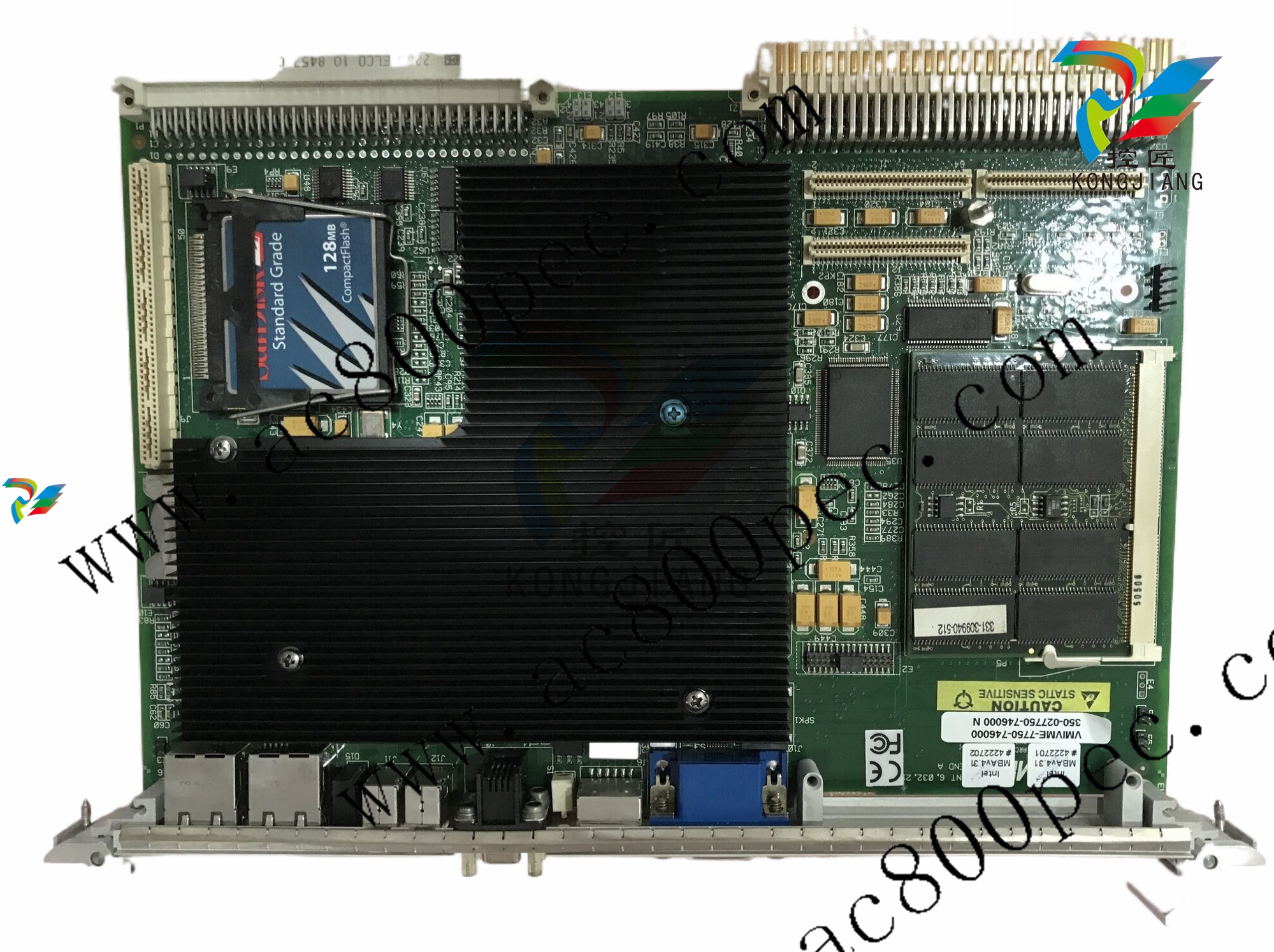

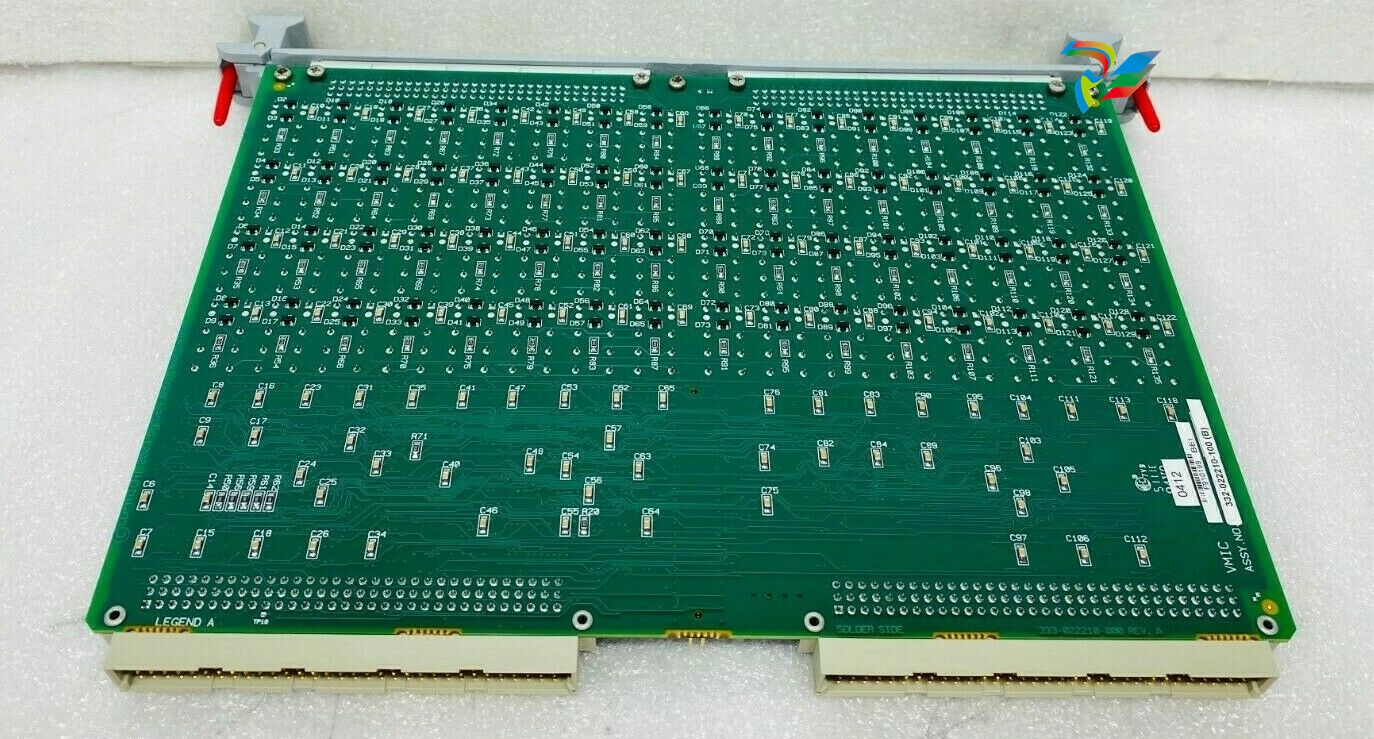

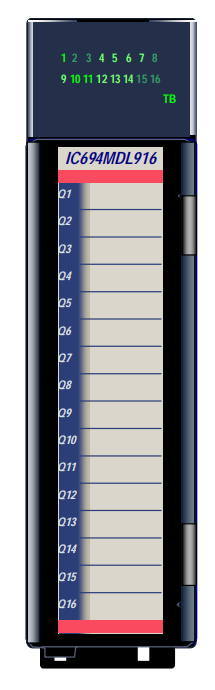

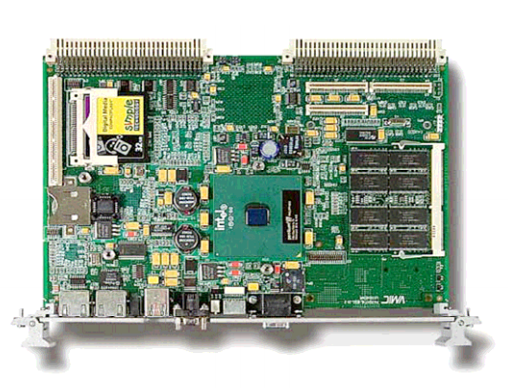

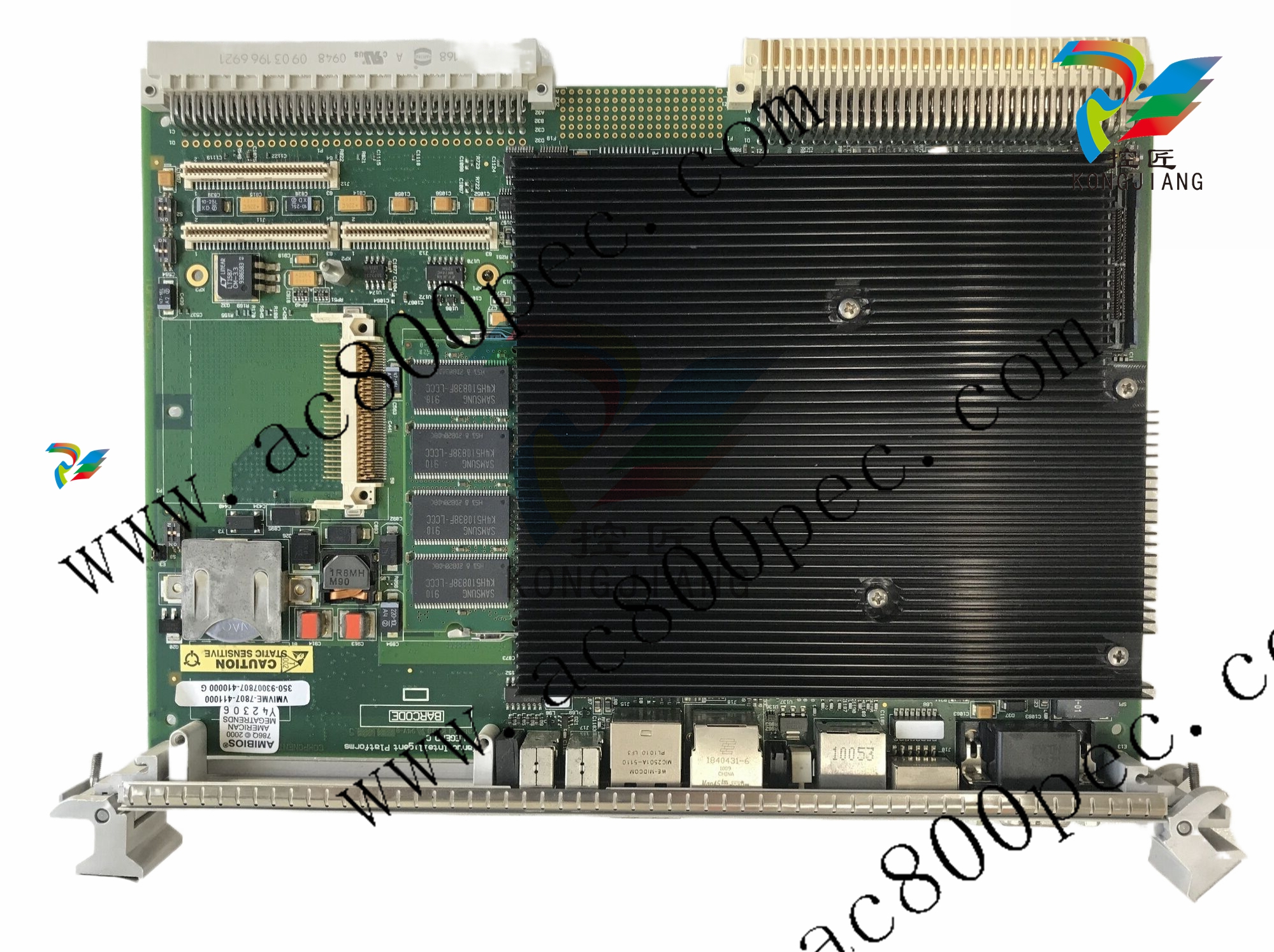

1.2.1 Controller, I/O and fieldbus cards

The hardware consists of controller cards, I/O cards and fieldbus cards.

In the controller a CPU is located and it is in the controller that the program containg

information on how to control the process is stored. This program is downloaded to the

controller from a workstation. The I/O cards and the fieldbus cards are capable of

sending or/and receiving signals to and from the devices. Hence, the I/O cards and

fieldbus cards send the signals that they get from the devices to the controller and the

signals that they get from the controller to the devices. The controller also sends

information to an operator interface, so that the operator of the process can monitor it.

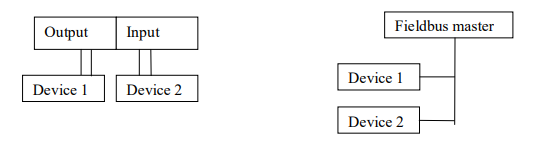

Figure 1.2 shows an overview of the connections for an automation system.

Figure 1.2. Overview of the connections for an automation system. A device is connected to an I/O card

or a fieldbus card. The controller communicates with the I/O cards and the fieldbus cards and is connected

to a workstation. The program is downloaded from a workstation to the controller.

Figure 1.3. The network is reduced when using a fieldbus. Fieldbus cards allow communication in both

directions and the wiring is much less when using fieldbus cards.

In this project three fieldbus cards are used; Foundation Fieldbus, Profibus and ASInterface. Foundation Fieldbus and Profibus handle analogue signals and AS-i only

handles discrete signals.

The communication technology for all three fieldbus cards follows a standard model