GEGenerator Protection System Generator Protection, Control and Asset Management

Overview

The relay features generator unbalance, generator differential, over excitation, loss of

excitation, 3rd harmonic neutral undervoltage, over and under frequency, synchrocheck

and other essential functions with a basic order option. Additionally available with an

advanced order option are overall differential (to protect the transformer-generator

combined), directional overcurrent elements, restricted ground fault, 100% stator ground,

out-of-step protection, rate of change of frequency, power factor, harmonic detection,

frequency out-of-band accumulation and others. An optional RTD module allows for

thermal protection and monitoring. An optional analog inputs/outputs module allows for

monitoring of generator excitation current, vibration and other parameters.

These relays contain many innovative features. To meet diverse utility standards and

industry requirements, these features have the flexibility to be programmed to meet

specific user needs. This flexibility will naturally make a piece of equipment difficult to

learn. To aid new users in getting basic protection operating quickly, setpoints are set to

typical default values and advanced features are disabled. These settings can be

reprogrammed at any time.

Programming can be accomplished with the front panel keys and display. Due to the

numerous settings, this manual method can be somewhat laborious. To simplify

programming and provide a more intuitive interface, setpoints can be entered with a PC

running the EnerVista 8 Setup software provided with the relay. Even with minimal

computer knowledge, this menu-driven software provides easy access to all front panel

functions. Actual values and setpoints can be displayed, altered, stored, and printed. If

settings are stored in a setpoint file, they can be downloaded at any time to the front panel

program port of the relay via a computer cable connected to the USB port of any personal

computer.

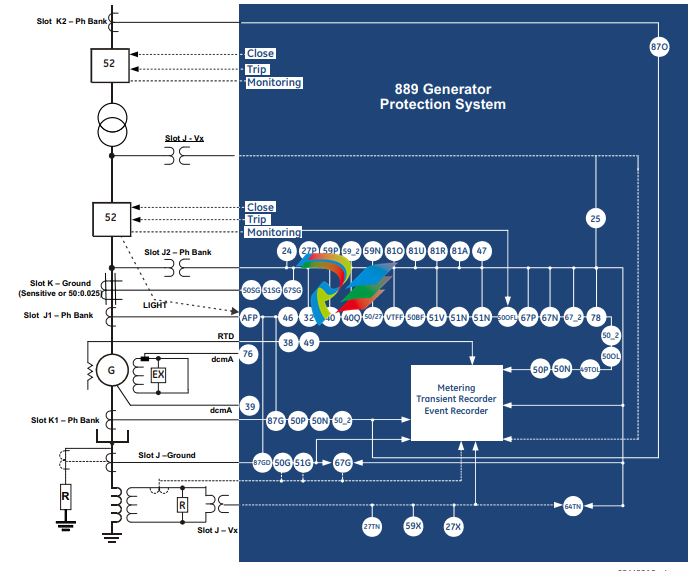

A summary of the available functions and a single-line diagram of protection and control

features is shown below. For a complete understanding of each feature operation, refer to

the About Setpoints chapter, and to the detailed feature descriptions in the chapters that

follow. The logic diagrams include a reference to every setpoint related to a feature and

show all logic signals passed between individual features. Information related to the

selection of settings for each setpoint is also provided.

Description of the 889 Generator Protection System

CPU

Relay functions are controlled by two processors: a Freescale MPC5125 32-bit

microprocessor that measures all analog signals and digital inputs and controls all output

relays, and a Freescale MPC8358 32-bit microprocessor that controls all the advanced

Ethernet communication protocols.

Analog Input and Waveform Capture

Magnetic transformers are used to scale-down the incoming analog signals from the

source instrument transformers. The analog signals are then passed through a 11.5 kHz

low pass analog anti-aliasing filter. All signals are then simultaneously captured by sample

and hold buffers to ensure there are no phase shifts. The signals are converted to digital

values by a 16-bit A/D converter before finally being passed on to the CPU for analysis.

The 'raw' samples are scaled in software, then placed into the waveform capture buffer,

thus emulating a digital fault recorder. The waveforms can be retrieved from the relay via

the EnerVista 8 Series Setup software for display and diagnostics.

Frequency

Frequency measurement is accomplished by measuring the time between zero crossings

of the composite signal of three-phase bus voltages, line voltage or three-phase currents.

The signals are passed through a low pass filter to prevent false zero crossings. Frequency

tracking utilizes the measured frequency to set the sampling rate for current and voltage

which results in better accuracy for the Discrete Fourier Transform (DFT) algorithm for offnominal frequencies.

The main frequency tracking source uses three-phase bus voltages. The frequency

tracking is switched automatically by an algorithm to the alternative reference source, i.e.,

three-phase currents signal if the frequency detected from the three-phase voltage inputs

is declared invalid. The switching will not be performed if the frequency from the

alternative reference signal is detected invalid. Upon detecting valid frequency on the

main source, the tracking will be switched back to the main source. If a stable frequency

signal is not available from all sources, then the tracking frequency defaults to the nominal

system frequency.

Phasors, Transients, and Harmonics

All waveforms are processed eight times every cycle through a DC decaying removal filter

and a Discrete Fourier Transform (DFT). The resulting phasors have fault current transients

and all harmonics removed. This results in an overcurrent relay that is extremely secure

and reliable and one that will not overreach.

Processing of AC Current Inputs

The DC Decaying Removal Filter is a short window digital filter, which removes the DC

decaying component from the asymmetrical current present at the moment a fault occurs.

This is done for all current signals used for overcurrent protection; voltage signals use the

same DC Decaying Removal Filter. This filter ensures no overreach of the overcurrent

protection.

The Discrete Fourier Transform (DFT) uses exactly one cycle of samples to calculate a

phasor quantity which represents the signal at the fundamental frequency; all harmonic

components are removed. All subsequent calculations (e.g. power, etc.) are based upon the

current and voltage phasors, such that the resulting values have no harmonic

components. RMS (root mean square) values are calculated from one cycle of samples

prior to filtering.

Protection Elements

All voltage, current and frequency protection elements are processed eight times every

cycle to determine if a pickup has occurred or a timer has expired. The voltage and current

protection elements use RMS current/voltage, or the magnitude of the phasor.

Security Overview

The following security features are available:

BASIC SECURITY

The basic security feature is present in the default offering of the 889 relay. The

889 introduces the notion of roles for different levels of authority. Roles are used as login

names with associated passwords stored on the device. The following roles are available

at present: Administrator, Operator, Factory and Observer, with a fixed permission

structure for each one. Note that the Factory role is not available for users, but strictly used

in the manufacturing process.

The 889 can still use the Setpoint access switch feature, but enabling the feature can be

done only by an Administrator. Setpoint access is controlled by a keyed switch to offer

some minimal notion of security.

CYBERSENTRY

The CyberSentry Embedded Security feature is a software option that provides advanced

security services. When the software option is purchased, the Basic Security is

automatically disabled.

CyberSentry provides security through the following features:

• An Authentication, Authorization, Accounting (AAA) Remote Authentication Dial-In

User Service (RADIUS) client that is centrally managed, enables user attribution, and

uses secure standards based strong cryptography for authentication and credential

protection.

• A Role-Based Access Control (RBAC) system that provides a permission model that

allows access to 889 device operations and configurations based on specific roles

and individual user accounts configured on the AAA server. At present the defined

roles are: Administrator, Operator and Observer.

• Strong encryption of all access and configuration network messages between the

EnerVista software and 889 devices using the Secure Shell (SSH) protocol, the

Advanced Encryption Standard (AES), and 128-bit keys in Galois Counter Mode (GCM)

as specified in the U.S. National Security Agency Suite B extension for SSH and

approved by the National Institute of Standards and Technology (NIST) FIPS-140-2

standards for cryptographic systems.

• Security event reporting through the Syslog protocol for supporting Security

Information Event Management (SIEM) systems for centralized cyber security

monitoring.

There are two types of authentication supported by CyberSentry that can be used to

access the 889 device:

• Device Authentication – in which case the authentication is performed on the

889 device itself, using the predefined roles as users (No RADIUS involvement).

– 889 authentication using local roles may be done either from the front panel or

through EnerVista.

• Server Authentication - in which case the authentication is done on a RADIUS server,

using individual user accounts defined on the server. When the user accounts are

created, they are assigned to one of the predefined roles recognized by the 889

– 889 authentication using RADIUS server may be done only through EnerVista.

FASTPATH: WiFi and USB do not currently support CyberSentry security. For this reason WiFi is

disabled by default if the CyberSentry option is purchased. WiFi can be enabled, but be

aware that doing so violates the security and compliance model that CyberSentry is

supposed to provide.

Enervista Viewpoint Monitor does not currently support CyberSentry security.

FASTPATH: With the CyberSentry security option, many communication settings cannot be changed

remotely. All communication settings can still be changed through the relay front panel.

When both 889 device and server authentication are enabled, the 889 automatically

directs authentication requests to the 889 device or the respective RADIUS server, based

on user names. If the user ID credential does not match one of the device local accounts,

the 889 automatically forwards the request to a RADIUS server when one is provided. If a

RADIUS server is provided, but is unreachable over the network, server authentication

requests are denied. In this situation, use local 889 device accounts to gain access to the

889 system.

USER ROLES

User Access Levels are used to grant varying permissions to specific user roles. User roles

are used by both Basic Security and CyberSentry.

The following user roles are supported:

• Administrator: The Administrator role has complete read and write access to all

settings and commands. The role does not allow concurrent access. The Administrator

role also has an operand to indicate when it is logged on.

• Operator: The Operator role is present to facilitate operational actions that may be

programmed and assigned to buttons on the front panel. The Operator has read/write

access to all settings under the command menu/section. The Operator can also use

the Virtual Input command under the control menu/section. The Operator can view

settings from EnerVista or the front panel but does not have the ability to change any

settings. This role is not a concurrent role.

• Observer: The Observer role has read-only access to all 889 settings. This role allows

concurrent access. The Observer is the default role if no authentication has been done

to the device. This role can download settings files and records from the device.

• Factory: This is an internal non-user accessible role used for manufacturing

diagnostics. The ability to enable or disable this role is a security setting that the

Administrator controls.

GENERAL RULES FOR USER ROLES WITH CYBERSENTRY

1. The only concurrent role is Observer. If the user is logged in through serial, front panel,

or over the network, that counts as the role being logged in for concurrency reasons.

2. Both EnerVista and the front panel provide a one-step logoff. For the front panel, the

root menu has a logoff command. From EnerVista right-clicking on a device and

providing a logoff function from the context menu is sufficient.

3. The EnerVista Login Screen has “User Name:” and “Password:” fields for the default

remote (Radius) authentication, but when a “Local Authentication” checkbox is

selected the “User Name:” field changes to a drop down menu where the user can

select one of the predefined roles on the 889

Must-read Information

The following general statements apply and are repeated in the relevant sections of the

manual.

FASTPATH: • WiFi and USB do not currently support CyberSentry security. For this reason WiFi is

disabled by default if the CyberSentry option is purchased. WiFi can be enabled, but be

aware that doing so violates the security and compliance model that CyberSentry is

supposed to provide.

• Before upgrading firmware, it is very important to save the current 889 settings to a

file on your PC. After the firmware has been upgraded, it is necessary to load this file

back into the 889.

• The SNTP, IRIG-B and PTP settings take effect after rebooting the relay.

• Commands may be issued freely through other protocols than Modbus (i.e., DNP, IEC

104, and, IEC 61850) without user authentication or encryption of data taking place,

even if the relay has the advanced security feature enabled.

• Note that the factory role password may not be changed.

• In 889 both DNP and IEC104 protocol can work at the same time, but consider that

there is only one point map. So, both protocols use the same configured points.

• The 52b contact is closed when the breaker is open and open when the breaker is

closed.

• The Phase Directional element responds to the forward load current. In the case of a

following reverse fault, the element needs some time – in the order of 8 ms – to

change the directional signal. Some protection elements such as Instantaneous

Overcurrent may respond to reverse faults before the directional signal has changed.

A coordination time of at least 10 ms must therefore be added to all the instantaneous

protection elements under the supervision of the Phase Directional element. If current

reversal is a concern, a longer delay – in the order of 20 ms – is needed.

• The same curves used for the time overcurrent elements are used for Neutral

Displacement. When using the curve to determine the operating time of the Neutral

Displacement element, substitute the ratio of neutral voltage to Pickup level for the

current ratio shown on the horizontal axis of the curve plot.

• If the 3-phase VT uses a delta connection and FREQUENCY INPUT is set to J2-3VT, the

positive sequence voltage is used as the supervision voltage. In such conditions, the

true supervision level is internally changed to 1/sqrt(3) of the user setting since the

base of VT here is the phase-phase voltage.

• To monitor the trip coil circuit integrity, use the relay terminals “FA_1 NO” and “FA_1

COM” to connect the Trip coil, and provide a jumper between terminals “FA_1 COM”

and “FA_1 OPT/V” voltage monitor).

• The relay is not approved as, or intended to be, a revenue metering instrument. If used

in a peak load control system, consider the accuracy rating and method of

measurement employed, and the source VTs and CTs, in comparison with the

electrical utility revenue metering system.

• In bulk oil circuit breakers, the interrupting time for currents is less than 25% of the

interrupting rating and can be significantly longer than the normal interrupting time.

• For future reference, make a printout of the conversion report immediately after the

conversion in case conversion reports are removed or settings modified from the 8

Series Setup Software.

Mechanical Installation

This section describes the mechanical installation of the 889 system, including dimensions

for mounting and information on module withdrawal and insertion.

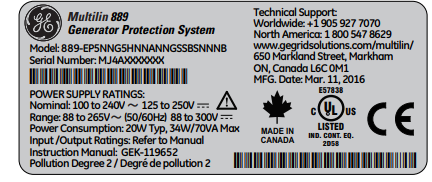

Product Identification

The product identification label is located on the side panel of the 889. This label indicates

the product model, serial number, and date of manufacture.

Figure 2-1: Product Label

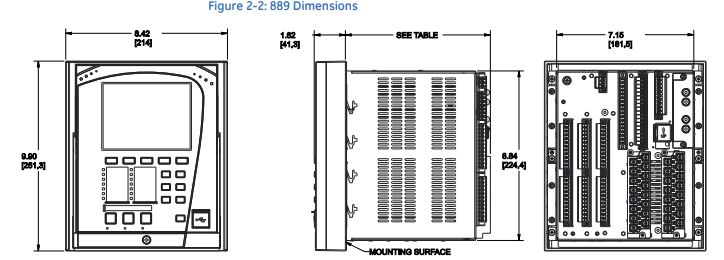

Dimensions

The dimensions (in inches [millimeters]) of the 889 are shown below. Additional dimensions

for mounting, and panel cutouts, are shown in the following sections.

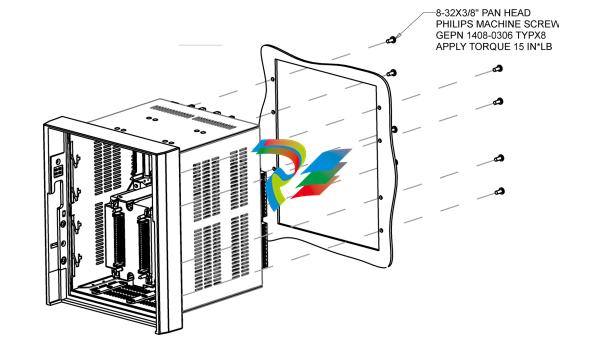

Mounting

The 889 unit can be mounted two ways: standard panel mount or optional tab mounting, if

required.

• Standard panel mounting:

From the front of the panel, slide the empty case into the cutout. From the rear of the

panel, screw the case into the panel at the 8 screw positions (see figures in Standard

panel mount section).

• Optional tab mounting:

The “V” tabs are located on the sides of the case and appear as shown in the following

figure. Use needle nose pliers to bend the retaining "V" tabs outward to about 90°. Use

caution and do not bend and distort the wall of the enclosure adjacent to the tabs. The

relay can now be inserted and can be panel wired.

Figure 2-3: “V” Tabs Located on Case Side

Standard Panel Mount The standard panel mount and cutout dimensions are illustrated below. CAUTION: To avoid the potential for personal injury due to fire hazards, ensure the unit is mounted in a safe location and/or within an appropriate enclosure. Figure 2-4: Standard panel mount

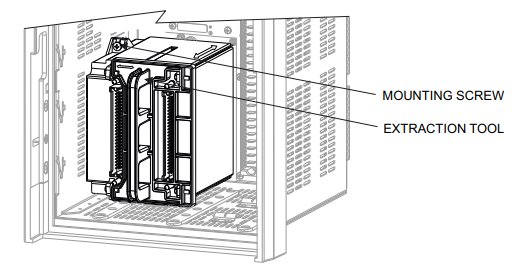

Removable Magnetic Module

IMPORTANT: Prior to the removal of the CT/VT magnetic module, all preparation steps below shall

be adhered to in order to prevent injury.

All current and voltage sources connected to the 8 Series relay must be identified

before starting the removal process.

Removal of the magnetic module from a relay installed in a power system shall only be

performed by suitably-qualified personnel.

Appropriate PPE is required based on the arc flash calculations.

CAUTION: LOTO (Lockout Tag Out) of the system is required prior to module removal/

replacement.

Follow the procedures outlined below to remove or replace the CT/VT magnetic module.

PREPARATION

1. Shut down and de-energize all systems connected to the 8 Series relay

2. Review all points in the section Cautions and Warnings.

IMPORTANT: An 8 Series relay, with the magnetic module removed, does NOT have an internal

automatic CT shorting mechanism.

CAUTION: Hazardous voltages can exist when opening the secondary circuits of live current

transformers. Make sure that in-field current transformer secondary circuits are

shorted out before making or removing any connection to the current transformer (CT)

input terminals of the device (i.e disconnection/connection of 8 Series CT Input

terminals or the internal CT/VT magnetic module).

.png)

.png)

.png)