ABB Collaborative Robots Keep Innovating, Leading the New Trend of Automation

Recently, ABB, a world-renowned leading enterprise in automation technology, has been continuously making efforts in the field of collaborative robots, constantly launching innovative products and technologies, which have brought new changes and opportunities for the automated production of various industries.

In 2021, ABB introduced the brand-new GoFa™ and Swifti™ series of collaborative robots, further expanding its collaborative robot product portfolio. These two types of robots are intuitively designed. Users can easily program and reprogram them by operating tablets or smartphones and using ABB's quick setup tools. Without special training, they can be directly operated within minutes after the products are installed. With higher payloads and faster speeds, the new products complement the dual-arm YuMi® and single-arm YuMi®, helping ABB to expand its market in high-growth fields such as electronics, healthcare, consumer goods, logistics, and food and beverage.

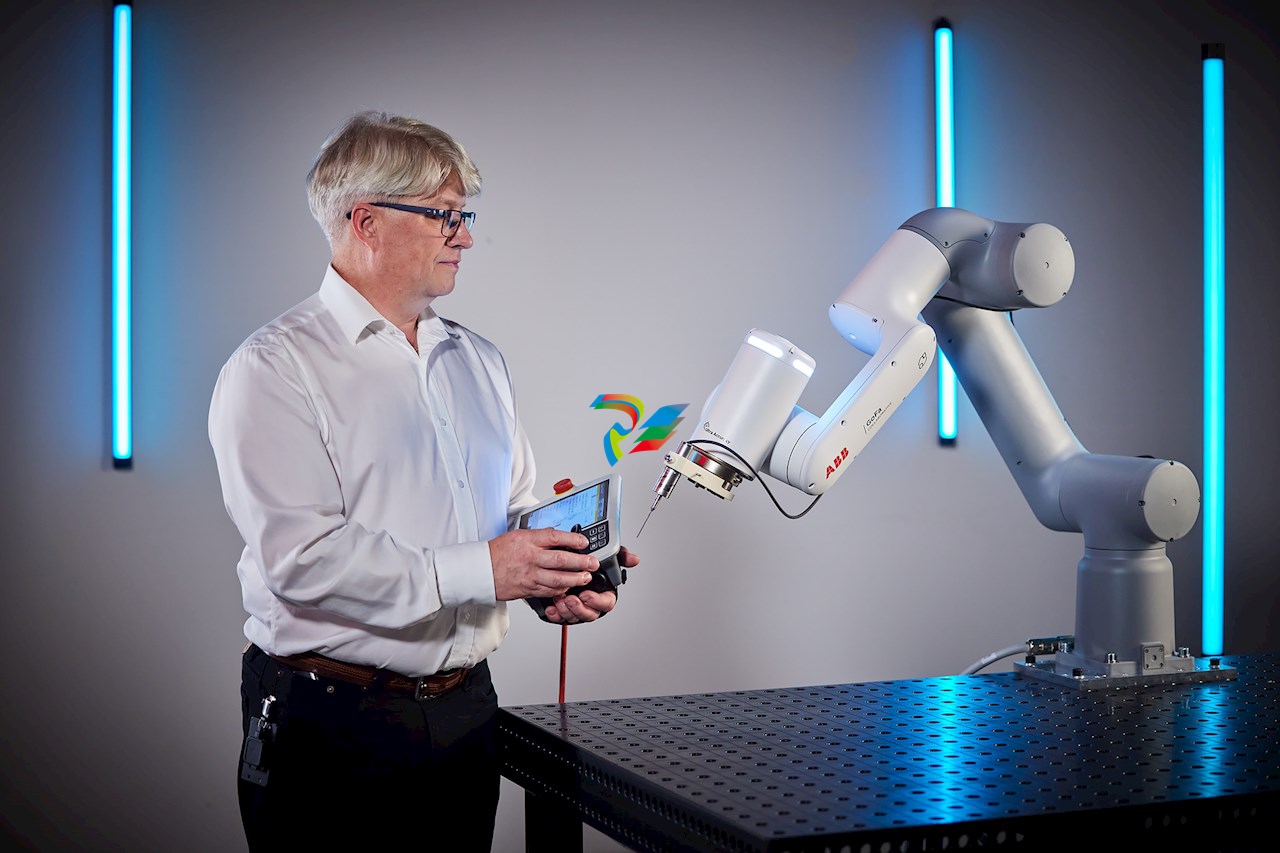

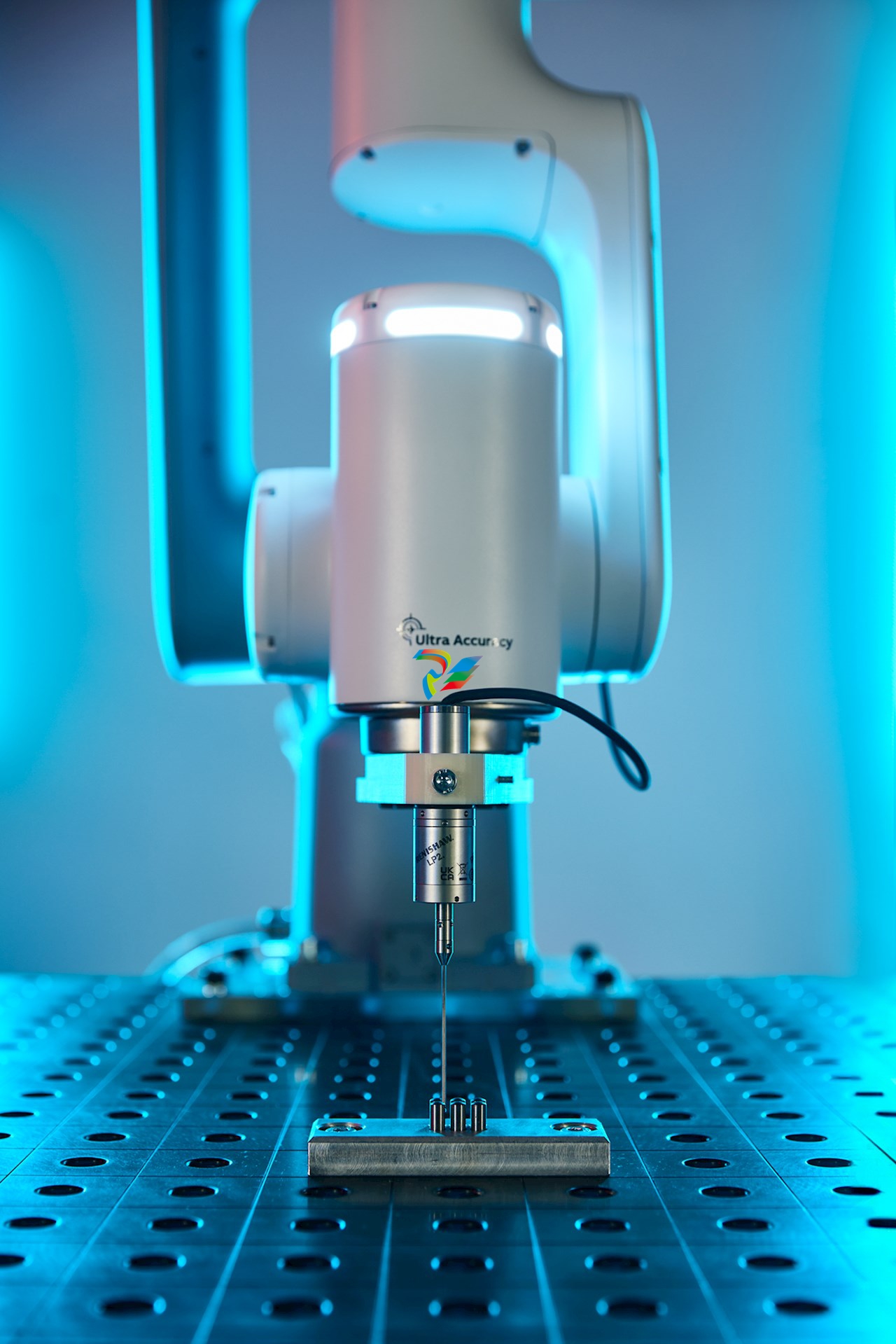

In 2023, ABB launched two new variants of collaborative robots, GoFa 10 and GoFa 12. They can handle payloads of up to 10 kilograms and 12 kilograms respectively, possess market-leading repeatability, and can closely collaborate with factory workers to complete a wider range of tasks. This not only solves the problems of skills and labor shortages for enterprises but also improves the safety and efficiency of production. Their Tool Center Point (TCP) speed can reach 2 meters per second, and the repeatability accuracy is 0.02 millimeters, which is superior to similar solutions. Moreover, these two robots have reached the IP67 protection level and can adapt to harsh production environments, performing excellently in tasks such as machine maintenance, welding, part handling, polishing, and assembly. At the 24th China International Industry Fair in 2024, ABB once again became the focus. The company newly launched the Ultra Accuracy (high-precision function option), which is applied to the GoFa collaborative robot series. This function enables the path accuracy of the GoFa collaborative robots to reach 0.03 millimeters, which is more than 10 times higher than that of other collaborative robots on the market. This innovative solution provides a better automation choice for industries with extremely high requirements for path accuracy, such as electronics, automobiles, aerospace, and metal processing. Marc Segura, President of ABB's Robotics Business, said: "Artificial intelligence, as a key driving force for the development of robotics technology, is shaping a brand-new era of industrial robots, empowering various industries to achieve more possibilities." ABB will continue to be committed to research and development and innovation, providing stronger technical support and solutions for the automation upgrade of the global manufacturing industry. It is believed that in the future, ABB's collaborative robots will play an important role in more industries and fields, promoting the continuous development of industrial automation.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)