ABB ACS850-04 Drive Modules: Hardware Manual Summary

ABB ACS850-04 Drive Modules: Hardware Manual Summary

This document serves as the hardware manual for ABB ACS850-04 drive modules, covering models from 160 to 560 kW (200 to 700 hp). It provides essential information for planning, installation, operation, maintenance, and technical specifications, ensuring safe and efficient use of the drive modules.

Introduction and Safety Instructions

The manual is intended for personnel involved in planning cabinet assembly, electrical installation, and providing end-user instructions for mechanical installation, cabling, and maintenance. It emphasizes strict adherence to safety instructions to prevent physical injury, death, or damage to equipment. Key safety warnings include:

Only qualified electricians are permitted to install and maintain the drive.

Always disconnect main power and wait 5 minutes for capacitors to discharge before working on the drive, motor, or motor cable.

Verify zero voltage with a multimeter before commencing work.

Do not work on control cables when power is applied to the drive or external control circuits.

Avoid insulation or voltage withstand tests on the drive.

Be aware of dangerously high voltages on motor cable and brake control terminals.

The Safe Torque Off function does not remove voltage from main and auxiliary circuits.

Proper grounding of the drive, motor, and adjoining equipment is crucial for safety and EMC.

For permanent magnet motors, ensure the motor cannot rotate and disconnect it before working on the drive, as a rotating PM motor can energize the drive's intermediate circuit.

Handle the heavy drive module carefully using lifting lugs and support legs to prevent overturning.

Beware of hot surfaces on heatsinks.

Prevent dust from entering the drive during installation.

Handle fiber optic cables by the connector, not the cable itself, and avoid touching fiber ends.

Wear a grounding wrist band when handling printed circuit boards due to their sensitivity to electrostatic discharge.

Do not run the motor over its rated speed, as overvoltage can damage or explode capacitors.

Ensure the motor and driven equipment are suitable for the drive's full speed range before operation.

Avoid activating automatic fault reset functions if dangerous situations can occur.

Control the motor using the control panel keys or I/O board commands, not an AC contactor.

Product Overview and Hardware Description

The ACS850-04 is a drive module designed for controlling asynchronous AC induction motors, permanent magnet motors, and ABB synchronous reluctance motors (SynRM motors). Its main circuit comprises an AC choke, rectifier, DC link, inverter, and an optional brake chopper (+D150) that dissipates surplus energy to a brake resistor during deceleration.

The standard unit features:

Lifting lugs and fastening brackets for installation.

Input and output cable connection busbars.

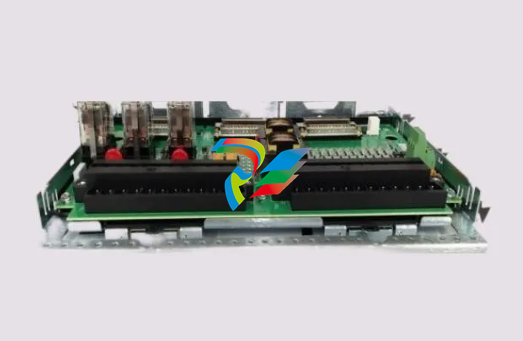

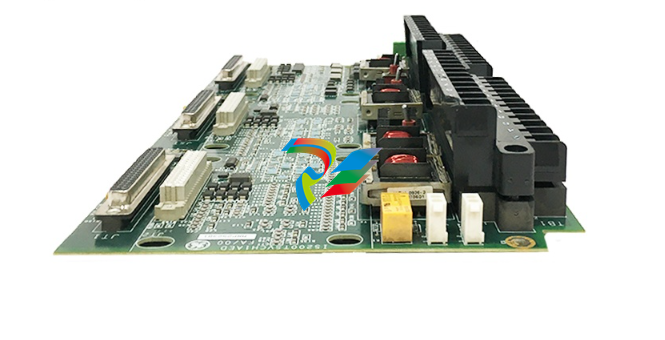

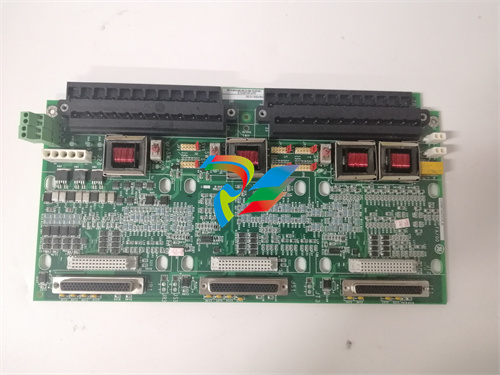

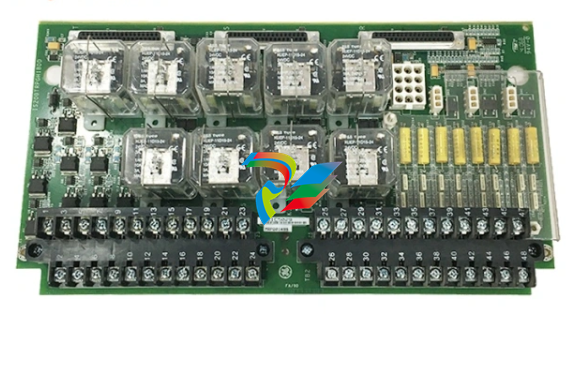

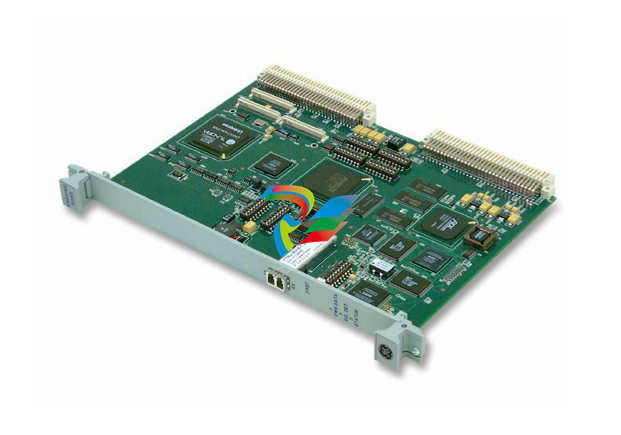

A circuit board compartment.

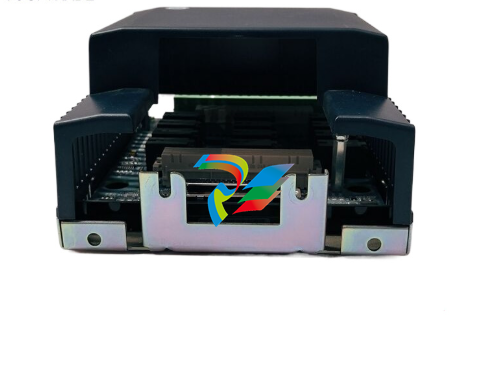

Main cooling fans.

Retractable support legs.

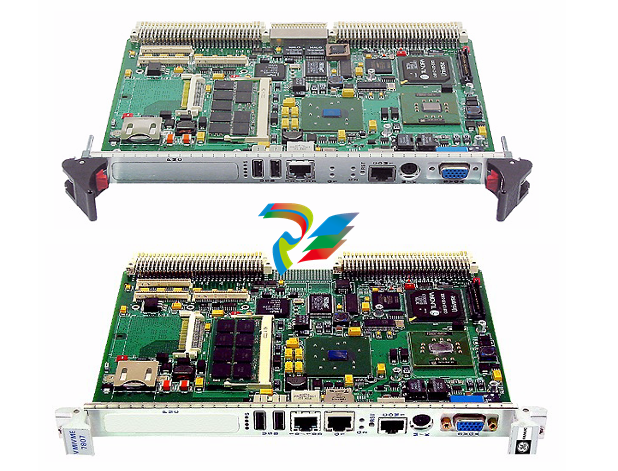

A control unit (JCU) with slots for optional I/O extension, encoder/resolver interface, and fieldbus adapter modules.

Optional selections include cabling panels (+H381 or +H383), DC busbars (+H356), various control panel and control unit configurations (e.g., +J400, +J410, +P905 for internal control unit), fieldbus adapter modules (e.g., PROFIBUS DP, PROFINET IO), I/O extension modules, and specialized control programs (e.g., Crane control program, SynRM control program).

Planning the Cabinet and Electrical Installation

Detailed guidance is provided for cabinet installation and electrical connections:

Cabinet Requirements: Use a sturdy cabinet that protects against contact, meets dust and humidity requirements, and has sufficient air inlet/outlet gratings for cooling.

Layout Planning: Design a spacious layout for easy installation and maintenance, considering cooling air flow, clearances, and cable support structures. Control boards should be placed away from main circuit components and hot parts.

Grounding: Ensure proper grounding of the drive module to the cabinet's PE busbar, either through fastening points or a separate grounding conductor.

EMC Planning: Minimize holes in the cabinet, ensure good galvanic connection between steel panels (welding or conductive EMC strips), and use 360° high-frequency grounding for cable shields at lead-throughs to suppress electromagnetic disturbances.

Cooling: Ensure sufficient ventilation of the installation site, adequate free space around components, and proper air inlet/outlet design to prevent hot air recirculation.

Cable Selection and Routing: Dimension input power and motor cables according to local regulations, using symmetrical shielded motor cables. Route motor cables away from other cable routes, crossing at right angles if necessary. All control cables must be shielded.

Protections: Install a hand-operated input disconnecting device. Protect the drive and input power cable with fuses (ultrarapid aR fuses or UL-recognized Class T/L fuses). The drive protects the motor cable and motor against short-circuits and thermal overload. For multiple motors, use separate circuit breakers/fuses for each motor.

Motor Compatibility: Use asynchronous AC induction motors, permanent magnet motors, or ABB SynRM motors. Ensure motor insulation system withstands maximum peak voltage at motor terminals, and consider optional du/dt filters, common mode filters (+E208), or insulated N-end bearings for protection.

Safety Functions: Implement Emergency Stop, Safe Torque Off, and ATEX-certified Safe Motor Disconnection functions as required.

Bypass Connection: If bypassing is needed, use mechanically or electrically interlocked contactors to prevent simultaneous closure. Never connect supply power to drive output terminals directly.

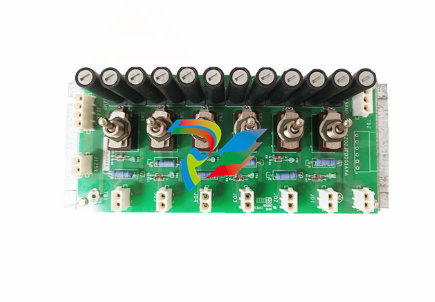

Brake Resistors: For high-capacity braking, optional brake choppers (+D150) and external resistors can be used. Select components based on braking power and heat dissipation capacity. Resistors must be installed outside the drive module in a well-cooled, non-flammable area.

.jpg)