Gränges Shanghai, China has installed many ABB Force Measurement products in their rolling mills and process lines

Gränges Shanghai, China has installed many ABB Force Measurement products in their rolling mills and process lines

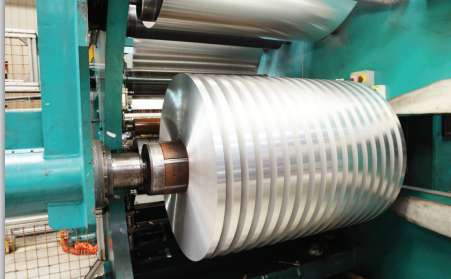

Gränges Shanghai’s (former Sapa Shanghai) rolling mills and process lines

are running with 6 Stressometer systems, 7 MTG-gauges, 2 Strip Scanner syste

ms and around 30 tension

load cells.

Measurement made easy

1.Background

In the 1980’s Gränges Sweden installed the first

Stressometer flatness system. Two decades later

Gränges Sweden continued investing in another

Stressometer system in order to scale up production.

Also Gränges expanded internationally and set up

upgraded Stressometer systems in the Gränges

Shanghai factory.

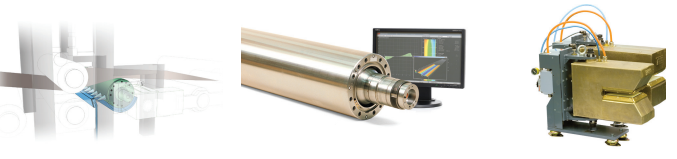

2.The investments continued and in 2004 two Stressometer systems were installed in the Tandem Cold Mill at Gränges Sweden. Also, at this time, Gränges carried through a MTG test installation in one of the rolling mills at the Finspång site in Sweden. The test resulted in very good feedback, highlighting the potential and benefits with the Millmate Thickness Gauging system (MTG) and the underlying PEC measurement technology, Pulsed Eddy Current technology. This test ended up with the first MTG-installation in the rolling mill.

3.In 2004 and 2005 Gränges Shanghai installed two Stressometer systems in CM1 and CM2 as well as a MTG in the levelling line.

4.In 2008 the investments continued and Gränges Shanghai installed another two Stressometer systems in the Tandem Cold Mill. Also MTG-gauges, Millmate Strip Scanners and LPBT and PRT load cells were installed in the TCM rolling mill.

5.The positive functions of the MTG and Stressometer systems have resulted in so far 7 MTG-gauges and 5 Stressometer flatness systems installed in the Gränges Shanghai mill. Further, in 2010, there were Stressometer, MTG, Millmate Strip Scanners as well as LPBT and PRT load cells installed in the Shanghai CM1 rolling mill. The latest additions at Gränges Shanghai is a Stressometer system in the hot rolling mill and a Stressometer system in CM4

“Gränges has very good communication with ABB

and we take benefit of the technical competence

and expertise they have on flatness, thickness,

tension, width and position measurement.”

What are the main benefits with ABB Force Measurement products

and what has been achieved?

We ask Mr Chen Peng, Process Control Engineer and Mr Bengt Jansson,

Strategic Projects Manager to comment the ABB Force Measurement

products in Gränges’ hot and cold rolling mills and process lines:

1.Stressometer system in the hot rolling

mill

”The hot Stressometer installation is

running very well and we have really

achieved better quality. The good tailout

from the hot rolling mill results in

high quality head-in to the cold rolling

mill. Further, we have increased rolling

speed and the yield is also better than

before. We also got good hot mill strip

flatness and benefit for cold rolling

speed performance and quality.”

2.Stressometer systems in the cold rolling mills ”The rolling mill performance is much better with the Stressometer flatness systems. We have increased the productivity step by step and the availability has improved a lot. The measurements are very stable and reliable and we have seen a considerable decrease of scrap due to the Stressometer installations

3.Further, in the long term we have increased the production speed from 300 m/min to 1500 m/min and thereby we have succeeded to increase our production efficiency considerably.”

5.Millmate Thickness Gauging (MTG)

in the cold rolling mills

”The accuracy is very good with the

MTG-gauges.

6.Further, MTG-gauges are alloyindependent and for the clad mode,

the measurement is insensitive to

the alloy chemistry.

7.We see a big advantage with the noncontact MTG thickness gauges having

very stable and reliable measurements

over time. Also, there is a minimum of

maintenance and there are no radiation

problems with MTG.”

Millmate Strip Scanner systems in the cold rolling mills ”The Millmate Strip Scanner system (MSS) is always working and the MSSsensors have been running perfectly for many years of operation. There is no maintenance and maintenance costs with MSS. MSS is very reliable as the sensor is unaffected by mill environment and the measurements are very stable. Coiler centering is very good with MSS. Also excellent recoiling without imperfections such as telescoping.”

Large PillowBlock Tensiometers (LPBT) in the cold rolling mills ”Tension control is one of the most important process parameters in a process line. In order to achieve good tension control you need reliable input of the actual tension. Therefore the selection of reliable tension load cells is crucial. For Gränges the choice was ABB’s Large PillowBlock Tensiometers and the underlying Pressductor® technology. We appreciate the reliable and accurate measurements with ABB’s Large PillowBlock Tensiometers.”Pressductor Radial Tensiometers (PRT) in the cold rolling mills and process lines For measuring tension with shaftmounted load cells, PRT system is a highquality system that provides exceptional and long-lasting performance. PRT load cells and tension electronics are designed for medium-tension and light-tension process lines used in light gauge and loop slitters. Easy to install and virtually maintenancefree, PRT tension measurement makes a significant contribution to more productive operations and improvements in product quality.

Gränges Aluminium (Shanghai) Ltd.

Gränges Aluminium (Shanghai) Ltd. is a wholly

owned subsidiary of Gränges AB in Sweden.

Gränges Aluminium (Shanghai) Ltd. together

with the sister company, Gränges Sweden AB,

are the only rolling mill plants in the world that

works exclusively with rolled aluminium to

produce brazed heat exchangers.

Gränges develops, manufactures and makets

value-added profiles, profile-based building systems

and heat exchanger strips. The business concept

is built on close cooperation with their customers

located all over the world.

In Shanghai Gränges began production in 1999

and over the years they have continuously

invested in enhancing their production capacity

and competencies in order to meet the always

growing market demand. Today the annual

production capacity has reach about 120,000 tons.

Gränges is concentrating all their resources

on one single task – to be the preferred partner

for manufacturers of brazed aluminium heat

exchangers.

For more information visit:

www.granges.com

Gränges Aluminium (Shanghai) Ltd.

Gränges Aluminium (Shanghai) Ltd. is a wholly

owned subsidiary of Gränges AB in Sweden.

Gränges Aluminium (Shanghai) Ltd. together

with the sister company, Gränges Sweden AB,

are the only rolling mill plants in the world that

works exclusively with rolled aluminium to

produce brazed heat exchangers.

Gränges develops, manufactures and makets

value-added profiles, profile-based building systems

and heat exchanger strips. The business concept

is built on close cooperation with their customers

located all over the world.

In Shanghai Gränges began production in 1999

and over the years they have continuously

invested in enhancing their production capacity

and competencies in order to meet the always

growing market demand. Today the annual

production capacity has reach about 120,000 tons.

Gränges is concentrating all their resources

on one single task – to be the preferred partner

for manufacturers of brazed aluminium heat

exchangers.

For more information visit:

www.granges.com

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)