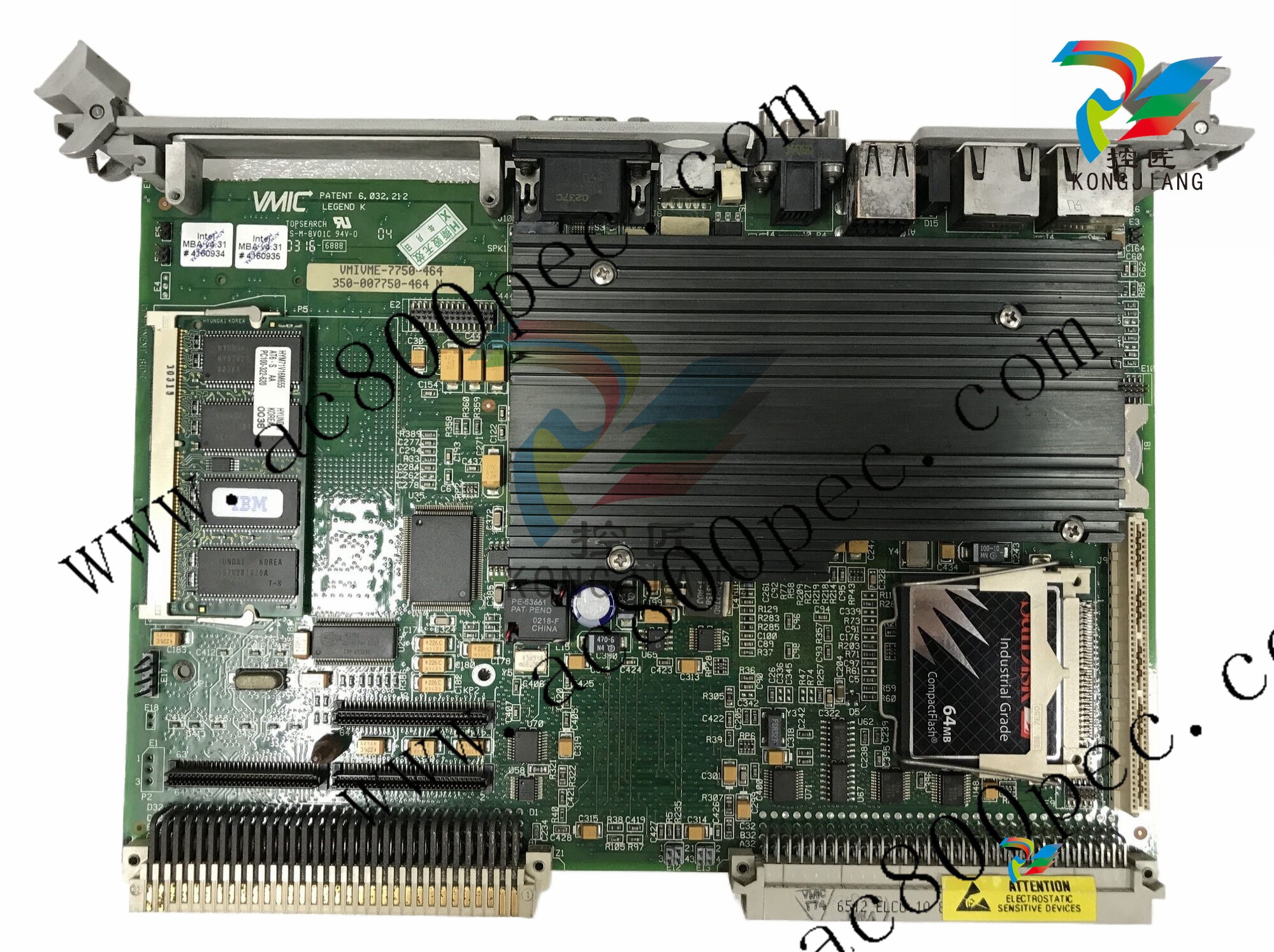

GE IS220PPRAH1A Emergency Turbine Protection Module

When selecting a protection module, consider factors such as:

Compatibility with existing control system components

Specific safety certification requirements

Need for advanced diagnostic capabilities

Long-term availability of spare parts and support

Integration with other protection and control systems

Consulting with GE application engineers can provide valuable guidance on selecting the most appropriate module for specific applications, particularly for complex installations or critical protection requirements.

ConclusionThe GE IS220PPRAH1A Emergency Turbine Protection Module represents a sophisticated solution for ensuring the safety and reliability of gas and steam turbines in power generation and industrial applications. With its comprehensive protection functions, robust design, and integration with the Mark VIe control system, it provides a critical safeguard for high-value turbine assets. By understanding the module's architecture, functionality, and implementation requirements, engineers and operators can effectively leverage its capabilities to build resilient protection systems that minimize the risk of turbine damage while maintaining high availability. As turbine control technology continues to evolve, the fundamental principles of independent, redundant, and diverse protection embodied in the IS220PPRAH1A remain essential for ensuring safe and reliable turbine operation. Whether implementing new turbine protection systems or upgrading existing installations, the technical considerations and best practices outlined in this article provide a foundation for successful deployment of the IS220PPRAH1A in a variety of industrial environments. |