GE IS220PPRAH1A Emergency Turbine Protection Module

GE IS220PPRAH1A Emergency Turbine Protection ModuleTechnical Overview and Implementation GuideMay 16, 2025 | Industrial Automation | |

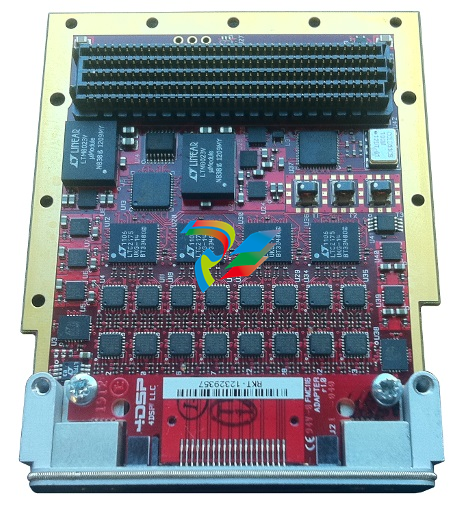

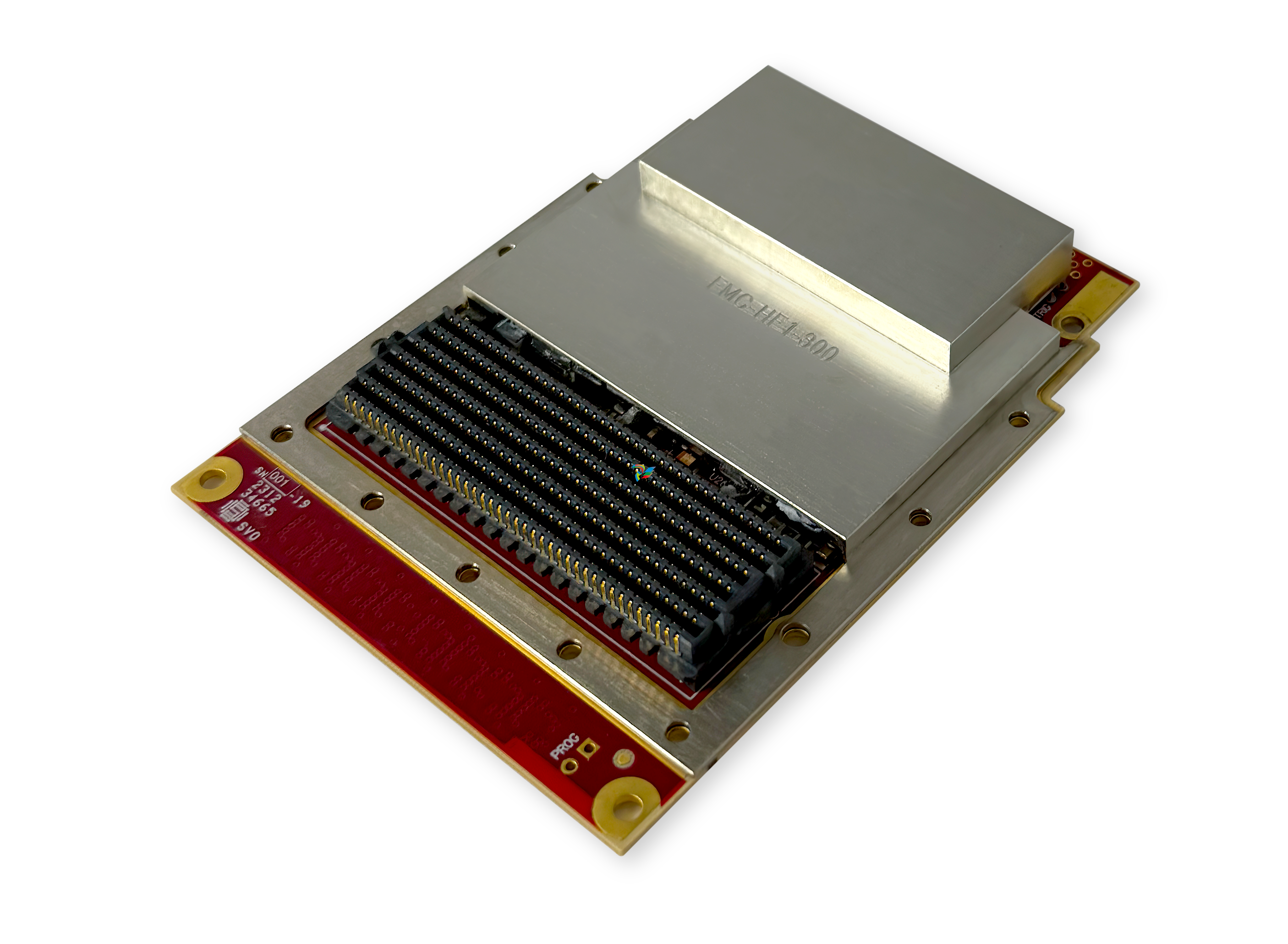

| Mark VIe Turbine Control System ComponentThe GE IS220PPRAH1A Emergency Turbine Protection Module is an essential component of the Mark VIe control system, designed to provide critical emergency protection for gas and steam turbine systems. This highly reliable module ensures turbine safety by monitoring and controlling key parameters in real-time, delivering fast response during emergency conditions. With its advanced architecture and robust design, the IS220PPRAH1A stands as a critical safeguard for high-value turbine assets in power generation and industrial applications, helping to prevent equipment damage and minimize operational downtime. |

IntroductionThe GE IS220PPRAH1A is an advanced Emergency Turbine Protection Module specifically engineered for the GE Speedtronic Mark VIe control system. As a critical safety component in turbine control applications, this module plays a pivotal role in ensuring the operational integrity and protection of gas and steam turbines in power generation facilities, oil and gas installations, and other industrial settings where turbine reliability is paramount. In today's power generation landscape, where turbine availability and equipment protection are directly linked to operational economics, the IS220PPRAH1A represents a sophisticated solution to turbine safety challenges. This technical article provides a comprehensive analysis of the module's architecture, functionality, integration considerations, and application scenarios to assist control system engineers and turbine operators in leveraging its capabilities effectively. | |

Technical Specifications | |

| Specification | Value |

|---|---|

| Part Number | IS220PPRAH1A |

| Series | Mark VI/VIe Turbine Control System |

| Manufacturer | General Electric |

| Product Type | Emergency Turbine Protection Module |

| Operating Temperature | -20°C to +55°C |

| Power Supply Voltage | Min: 27.4 VDC, Nominal: 28.0 VDC, Max: 28.6 VDC |

| Power Supply Current | Maximum 0.5 ADC |

| Compatible Terminal Board | IS200TREAH1A |

| Compatible Daughter Board | IS200WREAH1A |

| Speed Inputs | Six channels (configurable as three sets of speed pairs) |

| Speed Input Voltage Range | -15 VDC to +15 VDC |

| Contact Input Voltage | 0 to 32 VDC |

| E-stop Input Voltage | 18 to 140 VDC |

| Contact Outputs 1-2 | Up to 28 VDC, 7 ADC maximum |

| Contact Output 3 | Up to 28 VDC, 5 ADC maximum |

| Hazardous Location Rating | Approved for use in hazardous and non-hazardous locations |

System Architecture and ComponentsThe IS220PPRAH1A operates as part of a comprehensive turbine protection system, working in conjunction with specific terminal boards and daughter boards to create a complete protection solution. The module's architecture is designed with redundancy and reliability as core principles, ensuring that turbine protection remains intact even during component failures or abnormal operating conditions. Key System ComponentsThe complete turbine protection system using the IS220PPRAH1A typically includes:

This combination of components creates a comprehensive protection system that is approved for use in both hazardous and non-hazardous locations, making it suitable for a wide range of industrial environments. Architectural Features

| ||

Functional CapabilitiesThe IS220PPRAH1A provides a comprehensive set of protection functions specifically designed for turbine applications. These functions are implemented through a combination of firmware-based algorithms and hardware-enforced safety mechanisms, creating multiple layers of protection for the turbine system. Primary Protection FunctionsThe module implements several critical protection functions, including:

When any protection threshold is exceeded or abnormal condition detected, the PPRA module will trip the backup trip relays on the TREA terminal board and activate a trip signal to the primary control system, ensuring that the turbine is brought to a safe state rapidly and reliably. | ||

Speed Monitoring and ProtectionThe IS220PPRAH1A accepts six speed signals, configured as three sets of speed pairs, providing redundant speed measurement for reliable protection. This arrangement ensures that accurate speed information is available even if individual speed sensors fail. The module implements several speed-related protection functions:

This comprehensive approach to speed monitoring ensures that the turbine is protected against a wide range of potential issues, from simple overspeed conditions to more complex scenarios involving sensor failures or rapid changes in operating conditions. | ||

Integration and ConfigurationIntegrating the IS220PPRAH1A into a turbine control system requires careful planning and consideration of multiple factors. The following sections outline key aspects of the integration process. Hardware InstallationThe physical installation of the PPRA module involves several key steps:

Careful attention to wiring practices, grounding, and shielding is essential for ensuring reliable operation of the protection system, particularly for the speed sensor inputs which can be sensitive to electrical noise. | ||

Software ConfigurationConfiguration of the IS220PPRAH1A is performed through the GE ToolboxST software, which provides the interfaces necessary for defining protection parameters, alarm thresholds, and system behavior. The configuration process typically includes the following steps:

The configuration must be carefully validated to ensure that protection functions will operate correctly under all anticipated conditions, while avoiding nuisance trips that could impact plant availability unnecessarily. | ||

Application ScenariosThe IS220PPRAH1A is designed for use in a variety of turbine protection applications across different industries. The following sections highlight some of the key application scenarios where this module provides significant value. Gas Turbine ProtectionIn gas turbine applications, the IS220PPRAH1A provides critical protection against conditions that could lead to catastrophic failure, such as:

The module's independent operation from the primary control system ensures that protection remains available even if the main control system experiences failures, providing an essential safety net for high-value gas turbine assets. Steam Turbine ProtectionFor steam turbine applications, the IS220PPRAH1A addresses specific protection requirements, including:

| ||

Maintenance and TroubleshootingProper maintenance and troubleshooting procedures are essential for ensuring the continued reliable operation of the IS220PPRAH1A and associated protection systems. The following sections provide guidance on key maintenance and troubleshooting aspects. Preventive MaintenanceRegular preventive maintenance activities should include:

Comprehensive maintenance records should be maintained, documenting all inspections, tests, and any issues identified, along with corrective actions taken. Troubleshooting Common IssuesWhen issues arise with the protection system, systematic troubleshooting approaches can help identify and resolve problems efficiently. Common issues and troubleshooting steps include:

| ||

Best Practices for ImplementationImplementing the IS220PPRAH1A effectively requires attention to several best practices to ensure optimal protection system performance and reliability. System Design ConsiderationsWhen designing protection systems using the IS220PPRAH1A, consider the following best practices:

Testing and ValidationThorough testing and validation are essential for ensuring protection system reliability:

| ||

Series Comparison and Selection GuideGeneral Electric offers several variants of the emergency turbine protection module to address different application requirements. Understanding the differences between these variants is essential for selecting the most appropriate module for a specific application. | ||

| Model | Key Features | Typical Applications |

|---|---|---|

| IS220PPRAH1A | Original version with standard features for emergency turbine protection. Compatible with IS200TREAH1A terminal board and IS200WREAH1A daughter board. | Standard gas and steam turbine protection in power generation and industrial applications. |

| IS220PPRAS1A | Enhanced version with additional safety features. Compatible with IS200TREAS1A terminal board and IS200WREAS1A daughter board. | Applications requiring additional safety certification or enhanced protection features. |

| IS220PPRAS1B | Latest generation with updated hardware components and enhanced diagnostic capabilities. Compatible with IS200TREAS1A terminal board and IS200WREAS1A daughter board. | New installations and upgrades where the latest technology and enhanced diagnostics are desired. |