A-BSLC 5/01 and SLC 5/02 Modular Processors

mportant User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

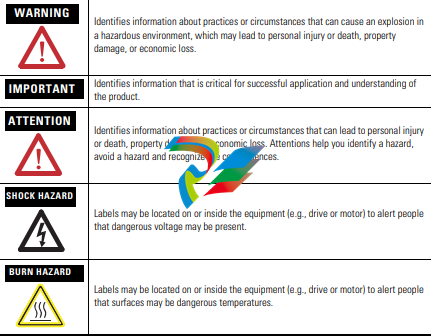

Throughout this manual, when necessary, we use notes to make you aware of safety considerations

Never install, remove, or wire any module while power is applied.

Also, do not expose processor modules to surfaces or other areas

that may typically hold an electrostatic discharge.

IMPORTANT Refer to page 12 for information on proper battery handling,

storage, and transportation.

WARNING • Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equipment unless

power has been switched off or the area is known to be

non-hazardous.

• Do not connect or disconnect components unless power has

been switched off or the area is known to be non-hazardous.

• All wiring must comply with N.E.C. article 501-4(b).

For general recommendations concerning installation safety requirements and

safety related work practices, refer to the requirements specific to your region.

• Europe: Reference the standards found in EN 60204 and your national

regulations.

• United States: Refer to NFPA 70E, Electrical Safety Requirements for

Employee Workplaces.

• Substitution of components may impair suitability for Class I, Division 2. • Do not replace components or disconnect equipment unless power has been switched off or the area is known to be non-hazardous. • Do not connect or disconnect components unless power has been switched off or the area is known to be non-hazardous. • All wiring must comply with N.E.C. article 501-4(b).Required Tools • medium blade screwdriver • programming equipment • a 1747-PIC, 1784-KTX, or 1784-PCMK communication interfaces

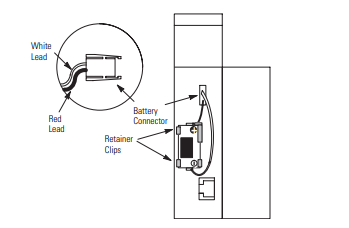

1. Open the door of the processor.

2. Remove the jumper from the battery connector socket. Store the jumper in a

safe place for possible future use without the battery.

3. Insert a new or replacement battery in the holder making sure it is held in by

the retainer clips.

4. Plug the battery connector into the socket. See the figure below

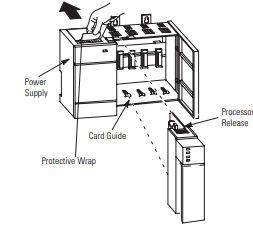

Install the Processor into the Chassis

Never install, remove, or wire any module while power is applied. Also, do not expose processor modules to surfaces or other areas that may typically hold an electrostatic discharge. Electrostatic discharge can damage integrated circuits or semiconductors if you touch backplane connector pins. If the equipment is not installed and used as described in the SLC 500 Modular Hardware Style User Manual, publication 1747-UM011, the protection provided by the equipment may be impaired.

Turn off power to the chassis where you will insert the processor. 2. Align the circuit board of the processor with the card guide of slot 0 in the 1746 chassis.

3. Gently slide the processor in until both the top and bottom retainer clips are

secured.

4. Remove the protective wrap after installing the processor.

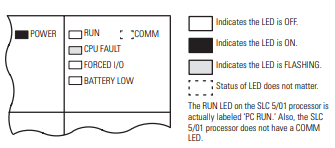

Apply Power to the Processor

To apply power to the processor:

1. Energize the chassis power supply.

2. Check the chassis power supply and processor LEDs. The power LED on the

power supply should be on and the fault LED on the processor should be

flashing

Load Your Software

Refer to the programming software documentation.

Establish Communications with the Processor

To establish communication with your processor:

1. Connect the 1747-PIC to the processor and your personal computer.

2. Set the communication parameters of the software to match the default

parameters of the processor:

• DH-485

• 19.2K baud

• Node Address = 1

Troubleshoot the Processor

Refer to the Troubleshooting chapter in the SLC 500 Modular Hardware Style User

Manual, publication 1747-UM011.

In addition refer to the SLC 500 Instruction Set Reference Manual, publication

1747-RM001. This manual contains explanations and examples for the entire

instruction set as well as for all status words and bits. It also contains explanations

for all possible fault codes found in status word S:6.

attery Storage

Store the lithium batteries in a cool, dry environment, typically +20° C to +25° C

(+68° F to +77° F) and 40% to 60% relative humidity.

Battery Transportation

One or Two Batteries

You can ship up to two batteries together within the United States without

restriction. Regulations governing shipment to or within other countries may differ.

Three or More Batteries

Procedures for the transportation of three or more batteries shipped together within

the United States are specified by the Department of Transportation (DOT) in the

Code of Federal Regulations, CFR49, “Transportation.” An exemption to these

regulations, DOT - E7052, covers the transport of certain hazardous materials

classified as flammable solids. This exemption authorizes transport of lithium

batteries by motor vehicle, rail freight, cargo vessel, and cargo-only aircraft,

providing certain conditions are met. Transport by passenger aircraft is not

permitted.

Shipment of depleted batteries for disposal may be subject to specific regulation of

the countries involved or to regulations endorsed by those countries, such as the

A Restricted Articles Regulations of the International Air Transport Association,

Geneva, Switzerland.

For disposal, batteries must be packaged and shipped in accordance with

transportation regulations, to a proper disposal site. The U.S. Department of

Transportation authorizes shipment of “Lithium batteries for disposal” by motor

vehicle only in regulation 173.1015 of CFR 49 (effective January 5, 1983). For

additional information contact:

U.S. Department of Transportation

Research and Special Programs Administration

400 Seventh Street, S.W.

Washington, D.C. 20590

Although the Environmental Protection Agency at this time has no regulations

specific to lithium batteries, the material contained may be considered toxic,

reactive, or corrosive. The person disposing of the material is responsible for any

hazard created in doing so. State and local regulations may exist regarding the

disposal of these materials.

For a lithium battery material safety data sheet, contact the manufacturer.

IMPORTANT Regulations for transportation of lithium batteries are periodically

revised.

ATTENTION Do not incinerate or dispose of lithium batteries in general trash

collection. Explosion or violent rupture is possible. Batteries

should be collected for disposal in a manner to prevent against

short circuiting, compacting, or destruction of case integrity and

hermetic seal.

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in

using its products. At http://support.rockwellautomation.com, you can find

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running:

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning and needs to be returned:

Allen-Bradley, Rockwell Automation, TechConnect, SLC, SLC 500, and RSLogix 500 are trademarks of Rockwell Automation,

Inc.

Trademarks not belonging to Rockwell Automation are the property of their respective companies.

United States 1.440.646.3434

Monday – Friday, 8am – 5pm EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

.png)

.png)

.png)