A-BSLC 5/01 and SLC 5/02 Modular Processors

mportant User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

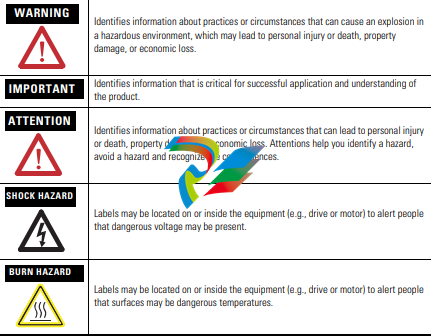

Throughout this manual, when necessary, we use notes to make you aware of safety considerations

Never install, remove, or wire any module while power is applied.

Also, do not expose processor modules to surfaces or other areas

that may typically hold an electrostatic discharge.

IMPORTANT Refer to page 12 for information on proper battery handling,

storage, and transportation.

WARNING • Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equipment unless

power has been switched off or the area is known to be

non-hazardous.

• Do not connect or disconnect components unless power has

been switched off or the area is known to be non-hazardous.

• All wiring must comply with N.E.C. article 501-4(b).

For general recommendations concerning installation safety requirements and

safety related work practices, refer to the requirements specific to your region.

• Europe: Reference the standards found in EN 60204 and your national

regulations.

• United States: Refer to NFPA 70E, Electrical Safety Requirements for

Employee Workplaces.

• Substitution of components may impair suitability for Class I, Division 2. • Do not replace components or disconnect equipment unless power has been switched off or the area is known to be non-hazardous. • Do not connect or disconnect components unless power has been switched off or the area is known to be non-hazardous. • All wiring must comply with N.E.C. article 501-4(b).Required Tools • medium blade screwdriver • programming equipment • a 1747-PIC, 1784-KTX, or 1784-PCMK communication interfaces

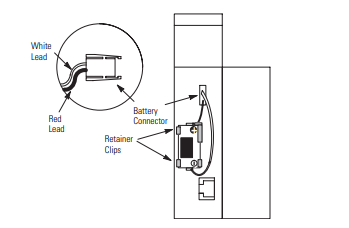

1. Open the door of the processor.

2. Remove the jumper from the battery connector socket. Store the jumper in a

safe place for possible future use without the battery.

3. Insert a new or replacement battery in the holder making sure it is held in by

the retainer clips.

4. Plug the battery connector into the socket. See the figure below

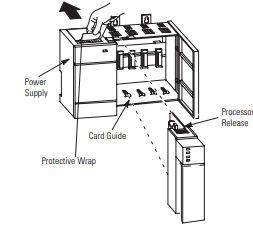

Install the Processor into the Chassis

Never install, remove, or wire any module while power is applied. Also, do not expose processor modules to surfaces or other areas that may typically hold an electrostatic discharge. Electrostatic discharge can damage integrated circuits or semiconductors if you touch backplane connector pins. If the equipment is not installed and used as described in the SLC 500 Modular Hardware Style User Manual, publication 1747-UM011, the protection provided by the equipment may be impaired.

Turn off power to the chassis where you will insert the processor. 2. Align the circuit board of the processor with the card guide of slot 0 in the 1746 chassis.

3. Gently slide the processor in until both the top and bottom retainer clips are

secured.

4. Remove the protective wrap after installing the processor.

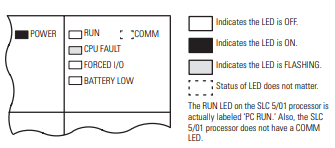

Apply Power to the Processor

To apply power to the processor:

1. Energize the chassis power supply.

2. Check the chassis power supply and processor LEDs. The power LED on the

power supply should be on and the fault LED on the processor should be

flashing

Load Your Software

Refer to the programming software documentation.

Establish Communications with the Processor

To establish communication with your processor:

1. Connect the 1747-PIC to the processor and your personal computer.

2. Set the communication parameters of the software to match the default

parameters of the processor:

• DH-485

• 19.2K baud

• Node Address = 1

Troubleshoot the Processor

Refer to the Troubleshooting chapter in the SLC 500 Modular Hardware Style User

Manual, publication 1747-UM011.

In addition refer to the SLC 500 Instruction Set Reference Manual, publication

.png)

.png)