GEInstallation and Maintenance Manual

Copyright 1995. Bently Nevada, LLC.

All rights reserved.

The information contained in this document is subject to change without notice.

The following are trademarks of General Electric Company in the United States and other

countries:

Bently Nevada, System 1, Keyphasor

The following are trademarks of the legal entities cited:

Velostat is a trademark of 3M Company.

Windows is a tradmemark of Microsoft Corporation.

Modbus is a trademark of Modbus-IDA.

Notice:

This manual does not contain all the information required to operate and maintain

the product. Refer to the following manuals for other required information.

3500 Monitoring System Rack Configuration and Utilities Guide

(129777-01)

• guidelines for using the 3500 Rack Configuration software for setting the operating

parameters of the module

• guidelines for using the 3500 test utilities to verify that the input and output

terminals on the module are operating properly

3500 Monitoring System Computer Hardware and Software Manual

(128158-01)

• instructions for connecting the rack to 3500 host computer

• procedures for verifying communication

• procedures for installing software

• guidelines for using Data Acquisition / DDE Server and Operator Display Software

• procedures and diagrams for setting up network and remote communications

3500 Field Wiring Diagram Package (130432-01)

• diagrams that show how to hook up a particular transducer

• lists of recommended wiring

Operation and Maintenance Manuals for all the modules installed in the

rack

Product Disposal Statement

Customers and third parties, who are not member states of the European Union, who are

in control of the product at the end of its life or at the end of its use, are solely

responsible for the proper disposal of the product. No person, firm, corporation,

association or agency that is in control of product shall dispose of it in a manner that is

in violation of any applicable federal, state, local or international law. Bently Nevada LLC

is not responsible for the disposal of the product at the end of its life or at the end of its

use.

1. Receiving and Handling Instructions

This will be a short overview of the entire section.

1.1 Receiving Inspection

Visually inspect the system for obvious shipping damage. If you detect shipping

damage, file a claim with the carrier and submit a copy to Bently Nevada, LLC.

1.2 Handling and Storage Considerations

Proper handling and storing of printed circuit boards is extremely critical. Circuit

boards contain devices that are susceptible to damage when exposed to

electrostatic charges. Damage caused by obvious mishandling of the board will

void the warranty. To avoid damage, observe the following precautions in the

order given.

Application Advisory

Machinery protection will be lost when

you remove all power from the rack.

• Do not discharge static electricity onto the circuit board. Avoid tools or

procedures that would subject the circuit board to static damage.

Some possible causes of static damage include ungrounded soldering

irons, nonconductive plastics, and similar materials.

• Use a suitable grounding strap (such as 3M Velostat® No. 2060) to

ground yourself before handling or performing maintenance on a

printed circuit board.

• Transport and store circuit boards in electrically conductive bags or

foil.

• Use extra caution during dry weather. Relative humidity less than 30%

tends to multiply the accumulation of static charges on any surface.

When performed properly, you may remove modules from or install modules into

the rack while power is applied to the rack. Refer to << Section reference to

“Module Installation in section 4 >> for the proper procedure.

2. General Information

Monitoring and computerized vibration information systems provide the

information you need to assess the mechanical condition of rotating and

reciprocating machinery. These systems continuously measure and monitor

various supervisory parameters and provide crucial information for early

identification of machinery problems such as imbalance, misalignment, shaft

crack, and bearing failures. As such, these systems are an efficient and effective

means of satisfying plant management, engineering, and maintenance concerns

for:

• Increasing plant safety by minimizing the occurrence of hazardous

conditions or catastrophic failures.

• Improving product quality by minimizing process variances caused by

improperly operating equipment.

• Maximizing plant availability by servicing only those machines that

require it and providing more efficient turnarounds.

• Reducing plant operating costs by minimizing unplanned shutdowns

and by making more efficient use of maintenance resources.

For protection of critical machinery, we highly recommend that you permanently

install continuous monitoring systems. The term "protection" means that the

system can shut down machinery on alarm, without human interaction. These

systems include applicable transducers, each with its own dedicated monitoring

circuitry and alarm setpoints. The 3500 Monitoring System is the newest addition

to the family of continuous monitoring systems offered by Bently Nevada, LLC.

2.1 3500 Monitoring System

The 3500 is a full-feature monitoring system whose design incorporates the latest

in proven processor technology. In addition to meeting the above stated criteria,

the 3500 adds benefit in the following areas:

• Enhanced operator information

• Improved integration to plant control computer

• Reduced installation and maintenance cost

• Improved reliability

• Intrinsic Safety (IS) option

The following sections discuss these benefits in more detail.

2.1.1 Enhanced Operation Information

The 3500 design includes features to both enhance the operator's information

and present this information so that the operator may easily interpret it. These

features include:

• Improved data set

- Overall amplitude

- Probe gap voltage

- 1X amplitude and phase

- 2X amplitude and phase

- Not 1X amplitude

• Windows®-based Operator Display Software

• Data displayed at multiple locations

2.1.2 Improved Integration to Plant Control Computer

The 3500 improves integration to the plant control computer with:

• Communication Gateways supporting multiple protocols

• Time synchronized vibration and process information

2.1.3 Reduced Installation and Maintenance Costs

The 3500 system provides the following cost-saving features:

• Reduced cabling costs

• Downward product compatibility

• Improved space utilization

• Easier configuration

• Reduced spare parts

• Improved serviceability

2.1.4 Improved Reliability

The 3500 offers several features to improve system reliability.

• Redundant power supplies available

• Triple Modular Redundant (TMR) monitors and relay cards available

2.1.5 Intrinsic Safety Option

If you wish to monitor equipment that is located in hazardous atmospheres, the

3500 Monitoring System has a range of I/O modules with internal zener barriers.

These modules provide an Intrinsically Safe interface between the 3500 rack and

the transducers located in the hazardous area.

2.1.6 Multiple Output Interfaces

You can conveniently adjust monitor options (such as full scale ranges,

transducer inputs, recorder outputs, alarm time delays, alarm voting logic, and

relay configuration) in the field via software. Modular system design employs

plug-in components which allow easy servicing and expansion.

The following three independent interfaces are available with the 3500 system:

• Data Manager Interface (Transient Data Interface External or Dynamic

Data Interface External)

• Configuration/Data port

• Communications Gateway (support for Programmable Logic

Controllers, Process Control Computers, Distributed Control Systems,

and PC-based Control Systems)

These interfaces allow you to easily view monitored parameters and their

statuses in the following ways:

• System 1® Software

• Bently Nevada™ 3500 Operator Display Software

• Remote display panel

• DCS or PLC display

Convenient front panel coaxial connectors provide dynamic transducer signals

and allow you to connect diagnostic or predictive maintenance instruments.

2.2 Common Features

The common features of the modules in the 3500 rack include hot insertion or

removal of modules and external and internal termination of the wiring.

2.2.1 Hot Insertion or Removal of Modules

When performed properly, you can remove and replace any module while the

system is under power without affecting the operation of any unrelated modules.

If the rack has 2 power supplies, removing or inserting a power supply will not

disrupt the operation of the 3500 rack. See <<Section reverence: “Module

Installation in section 4 >> for the proper procedure.

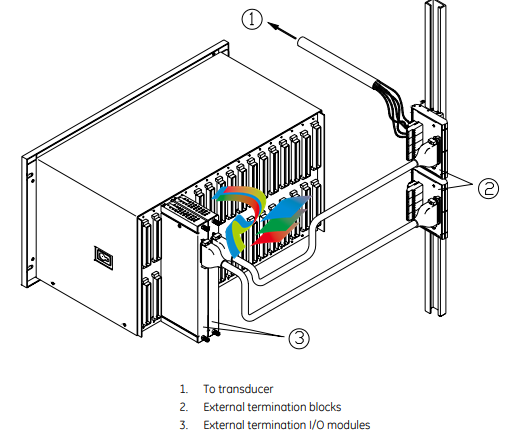

2.2.2 External and Internal Termination

External termination uses multi-conductor cables to connect the I/O modules to

the terminal blocks. These blocks simplify connecting many wires to the rack in

tight areas. External termination is not available on I/O modules with internal

zener barriers

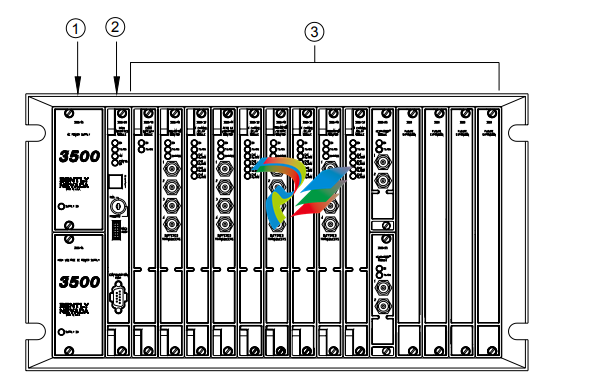

3500 System Components

The 3500 Monitoring System consists of modules that fit into a rack. Figure 2-3

shows a full-size 3500 system rack and system components. Note that the fullsize rack has 14 monitor slot positions. The Mini-rack (not shown) is similar, but

has 7 monitor slot positions to the right of the power supplies and Rack Interface

Module.

1. 1 or 2 power supplies

2. Rack Interface Module (standard, Transient Data Interface, (TDI), Triple Modular Redundant (TMR) and TMR TDI)

3. Monitoring slot positions:

- Monitor module

- Keyphasor® module (2 maximum)

- Relay module

- Communication Gateway module

- Display module. For the System Face Mount you must install the Display Interface Module in Slot 15.

- 3500/04-01 Earthing Module. Intallations that use Inernal Barrier I/Os require 1 Earthing Module per rack.

Figure 2-3: 3500 Rack (Full-Size)

The following sections list the function of each module. Refer to the individual

operation and maintenance manuals for available options, detailed description,

operation and maintenance.

2.3.1 Weatherproof Housing

The weatherproof housing protects the 3500 rack from adverse environmental

effects, such as excessive moisture, dirt and grime, and even unclean air. The

weatherproof housing will not accommodate a Display Unit or VGA Display.

2.3.2 Rack

2 types of 3500 racks are available: the full-size 19-inch rack and the compact 12-

inch Mini-rack. Each rack requires you to install the Power Supplies and Rack

Interface Module (RIM) in specific locations. The full-size version offers 14

additional rack positions and the Mini-rack offers 7 additional rack positions. You

may use these positions to install any combination of modules. Both racks

support Standard (non-redundant) and Triple Modular Redundant (TMR)

configurations.

2.3.3 Power Supply

The Power Supply is a half-height module available in ac and dc versions. You

can install 1 or 2 power supplies in the rack. Each power supply can power a fully

loaded rack. When you install 2 power supplies in a rack, the supply in the lower

slot acts as the primary supply and the supply in the upper slot acts as the

backup supply. If the primary supply fails, the backup supply will provide power to

the rack without interrupting rack operation. The 3500 design allows you to

install any combination of power supply types.

Overspeed Detection and TMR Monitors require dual power supplies.

2.3.4 Rack Interface Module

The Rack Interface Module (RIM) is a full-height module that communicates with

the host (computer), a Bently Nevada™ Communication Processor, and the other

modules in the rack. The Rack Interface Module also maintains the System Event

List and the Alarm Event List. You can daisy-chain this module to the Rack

Interface Modules in other racks and to the Data Acquisition / DDE Server

Software. The 3500 Monitoring System Computer Hardware and Software Manual

shows how to daisy chain the Rack Interface Modules together. Rack Interface

Modules are available in Standard, Triple Modular Redundant and Transient Data

Interface versions.

2.3.5 Communication Gateway Module

The Communication Gateway Module is a full-height module that allows external

devices (such as a DCS or a PLC) to retrieve information from the rack and to set

up portions of the rack configuration. You can install more than one

Communication Gateway Module in the same rack. Communication Gateway

Modules are available for a variety of network protocols.

2.3.6 Monitor Module

The Monitor Modules are full-height modules that collect data from a variety of

transducers. You can install any combination of Monitor Modules in the 3500

rack.

2.3.7 Relay Module

Relay Modules provide relays that you can configure to close or open based on

channel statuses from other monitors in the 3500 rack. Relay modules are

available in 4-channel, 16-channel, and 4-channel Triple Modular Redundant

(TMR) versions.

The TMR Relay Module is a half-height 4-channel module that operates in a TMR

system. 2 half-height TMR Relay Modules must operate in the same slot. If you

remove the upper or lower Relay Module or the system declares one of the

modules as Not OK, then the other Relay Module will control the Relay I/O Module.

2.3.8 Keyphasor® Module

The Keyphasor Module is a half-height module that provides power for the

Keyphasor transducers, conditions the Keyphasor signals, and sends the signals

to the other modules in the rack. The Keyphasor Module also calculates the rpm

values sent to the host (computer) and external devices (DCS or PLC) and provides

buffered Keyphasor outputs. Each Keyphasor Module supports 2 channels. You

may place up to 2 Keyphasor Modules in a 3500 rack for a maximum of 4

Keyphasor channels. If you use 2 Keyphasor Modules, you must place them in the

same full-height slot and the modules will share a common I/O module.

2.3.9 Display Module

The 3500 system offers multiple display options.

The Display Interface Module can display rack data on an LCD-based Interface

unit or a 3rd-party Modbus® based display unit.

The VGA Display Module will display rack data on certain touch screen VGA

Displays.

The Integrated PC display is a complete rack mount touch screen PC pre-loaded

with rack configuration software and display utilities.

2.3.10 Earthing Module

The Earthing Module is a full-height module that provides a low resistance

connection (must be less than 1 Ω) from the 3500 rack to the plant’s intrinsically

safe earth ground. The module operates in conjunction with the 3500 internal

zener barrier I/O modules. Your application will require 1 Earthing Module per rack

when internal barrier I/O modules are used.

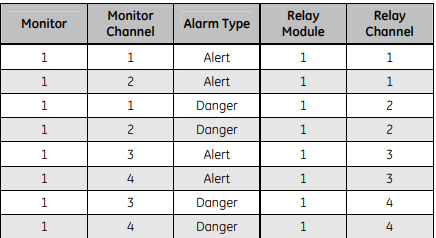

2.4 Standard Rack Relay Options

You can configure the standard (or non-TMR) 3500 rack to have individual relays,

bussed relays, or a combination of individual and bussed relays.

2.4.1 Individual Relays

A rack with individual relays contains 1 or more relay cards for each monitor

module. You can configure the monitor and relay modules within a 3500 rack in

many ways.

Example 1: The application uses 1 relay module 1 monitor module.

Table 2-1: 1 Relay Module Used With 1 Monitor Module

2.5 Intrinsic Safety — The 3500 Internal Barrier System

To provide Intrinsically Safe (IS) vibration and process variable monitoring, the

3500 system has a range of I/O modules with internal zener barriers. When you

install these modules in a 3500 rack with a 3500/04-01 Earthing Module, they

provide an integrated solution for explosion protection for approved Bently

Nevada transducer systems that are located within all classifications of

hazardous areas (surface industries other than mining).

2.5.1 3500 Internal Barrier System Restrictions

• You must install 1 earthing module in each rack in the internal barrier

system. The earthing module occupies 1 slot position in the rack when it

uses Internal Barrier I/O modules.

• You must change the grounding configuration of the 3500/15 Power

Supplies from the default factory setting. See the 3500/15 Operation and

Maintenance Manual (PN 129767-01) for instructions.

• You must isolate any RS-232 connection to any 3500 module. Monitors

that support RS232 connections include Rack Interface Modules,

Communication Gateways, and the 3500/95 PC Display. See the 3500/20

Operation and Maintenance Manual (PN 129768-01) for instructions. This

restriction does not apply to RS422 and RS485 connections to the rack.

Monitors that support RS422 and/or RS485 connections include the

3500/20, 3500/90, 3500/92, 3500/93, and 3500/95.

• You must not use the 3500/94 VGA Display in internal barrier systems.

• You must not use bussed transducers, as internal barrier systems do not

allow bussed transducers. See the TMR section of this manual for more

information.

2.5.2 3500 Internal Barrier System Features

• The earthing module supports dual IS Earth connections for cables with

cross-sectional areas up to 10 mm2. This module lets you test IS Earth

continuity online.

• The design of the internal barrier I/O modules provides the 2 inches (50

mm) of separation required between safe and hazardous area field wiring.

• The connectors for safe areas and hazardous areas have different field

wiring colors (green for safe and blue for hazardous) and connector

pitches. This helps to avoid incorrect field wiring installation.

• Quick connect/disconnect connectors simplify field wiring installation and

removal.

4.3 Replacing Modules

When replacing modules, whether main or I/O, you need not remove power from

the rack if the following procedures are followed. Refer to applicable steps in the

procedures above for removing or installing a module.

4.3.1 Main Modules

This assumes that you will replace only the main module of a monitor or power

supply. Before you remove any module, refer to the applicable manual to see how

this may affect rack behavior, and to identify any special handling requirements

that you may require for personal safety.

1. If necessary, upload and save the configuration of the module to be

replaced.

2. Remove the main module from the rack.

3. Install the new main module into the rack.

4. If necessary, configure the new main module.

5. Verify operation.

4.3.2 I/O Modules

This assumes that you will replace only the I/O module of a monitor or the PIM of

a power supply. Before you remove any module, refer to the applicable manual to

see how this may affect rack behavior, and to identify any special handling

requirements that you may require for personal safety.

1. If necessary, upload and save the configuration of the module to be

replaced.

2. Remove the main module from the rack.

3. Remove the field wiring from the I/O module.

4. Remove the old I/O module from the rack.

5. Install the new I/O module into the rack.

6. Connect the field wiring to the new I/O module.

7. Install the main module into the rack.

8. If necessary, re-configure the main module.

9. Verify operation

5.1 General Maintenance Instructions

You cannot repair the boards and components inside of 3500 modules in the field.

3500 rack maintenance consists of testing module channels to verify that they

are operating correctly. You should replace modules that are not operating

correctly with a spare.

When performed properly, you may remove modules from or install modules into

the rack while power is applied to the rack. Refer to Section 3 for the proper

procedure.

The 3500 Monitoring System is a high precision instrument that requires no

calibration. The functions of the 3500 modules, however, require verification at

regular intervals. You should verify all modules in the 3500 Monitoring System at

these maintenance intervals. The procedures in the Maintenance and

Troubleshooting sections of the module manuals describe the verification and

troubleshooting process.

5.2 Choosing a Maintenance Interval

Use the following approach to choose a maintenance interval:

1. Start with an interval of 1 year and then shorten the interval if any of the

following conditions apply:

• the monitored machine is classified as critical, or

• the 3500 rack is operating in a harsh environment such as in

extreme temperature, high humidity, or a corrosive atmosphere.

2. At each interval, use the results of the previous verifications and ISO

Procedure 10012-1 to adjust the interval.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)