EMERSONIPMC7126E/7616E I/O Module

the VME chassis.

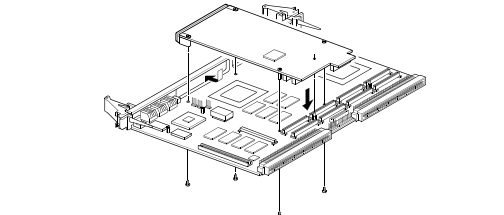

To install an IPMC module, refer to the following figure and proceed as follows:

1. Inspect the host board and the IPMC module for evidence of any damage to the PCB itself or

for evidence of any damage on the mating connectors.

2. If the host board is installed in a VMEbus card slot, carefully remove it and place it with

connectors P1and P2 facing you.

3. Remove the filler plate from the host board’s front panel. Position the IPMC module over the

center area of the slot 1 connectors as follows:

Figure 2-1. IPMC Installation

4. Line up the IPMC module’s front panel into the IPMC filler cutout slot on the host board’s front

panel.

5. Align connectors P11, P12, P13, P14, and P15 on the IPMC module with the mating connectors

on the host board and press firmly into place.

6. Insert the appropriate number of Phillips screws (typically 4) from the bottom of the host board

into the standoffs on the IPMC module and tighten the screws.

The host board is now ready to be installed into a VME chassis

Before You Install or Remove a Board

Boards may be damaged if improperly installed or handled. Please read and follow the

guidelines in this section to protect your equipment.

Observe ESD Precautions

Use ESD

Wrist Strap

ESD Emerson strongly recommends that you use an antistatic wrist strap and a conductive

foam pad when installing or upgrading a system. Electronic components, such as disk

drives, computer boards, and memory modules, can be extremely sensitive to

electrostatic discharge (ESD). After removing the component from its protective

wrapper or from the system, place the component flat on a grounded, static-free

surface (and, in the case of a board, component side up). Do not slide the component

over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing

an antistatic wrist strap (available at electronics stores) that is attached to an active

electrical ground. Note that a system chassis may not be grounded if it is unplugged.

Watch for Bent Pins or Other Damage

!

Caution

Caution Bent pins or loose components can cause damage to the board, the backplane, or

other system components. Carefully inspect your board and the backplane for both pin

and component integrity before installation.

ECC and our suppliers take significant steps to ensure there are no bent pins on the backplane

or connector damage to the boards prior to leaving our factory. Bent pins caused by improper

installation or by boards with damaged connectors could void the warranty for the backplane or

boards.

If a system contains one or more crushed pins, power off the system and contact your local

sales representative to schedule delivery of a replacement chassis assembly.

Use Caution When Installing or Removing Boards

When first installing boards in an empty chassis, we recommend that you start at the left of the

card cage and work to the right when cards are vertically aligned; in horizontally aligned cages,

work from bottom to top.

When inserting or removing a board in a slot adjacent to other boards, use extra caution to avoid

damage to the pins and components located on the primary or secondary sides of the boards.

Preserve EMI Compliance

!

Caution

Caution To preserve compliance with applicable standards and regulations for electromagnetic

interference (EMI), during operation all front and rear openings on the chassis or board

faceplates must be filled with an appropriate card or covered with a filler panel. If the

EMI barrier is open, devices may cause or be susceptible to excessive interference.

Recognize Different Injector/Ejector Lever Types

The modules you install may have different ejector handles and latching mechanisms. The

following illustration shows the typical board ejector handles used with ECC payload cards: (A)

Elma Latching, (B) Rittal Type II, (C) Rittal Type IV. All handles are compliant with the

CompactPCI specification and are designed to meet the IEEE1101.10 standards.

Each lever type has a latching mechanism to prevent the lever from being opened accidentally.

You must press the lever release before you can open the lever. Never force the lever. If the lever

does not open easily, you may not have pressed firmly enough on the release. If the lever does

not close easily, the board may not be properly seated in the chassis.

To open a lever, press the release and move the lever outward away from the faceplate.

To close a lever, move the lever inward toward the faceplate until the latch engages.

Verify Slot Usage

!

Caution

Caution Prevent possible damage to module components by verifying the proper slot usage for

your configuration.

Figure 2-2. Injector/Ejector Lever Types

Programming

Programing Details

The overall design of the IPMC712 and IPMC761 is based on the PowerPlus II architecture. The

programming characteristics for both modules conforms to the PowerPlusII Programming

Specification.

Note The PowerPlus II Programming Specification covers a large variety of programming

.png)

.png)

.png)