A-BLC Series Linear MotorsUSER MANUAL

2. Verify that the flatness of the surface to which the magnet plate is to be

mounted is 0.005 in. Total Indicator Reading (TIR) per 12.0 inches. This

specification correlates to the overall flatness requirement of 0.005 in.

(.127 mm).

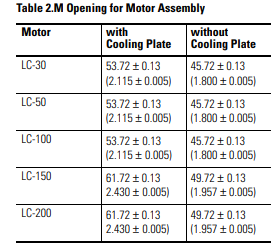

3. Prior to any component installation, verify that the opening for the

magnet plate and coil is dimensioned per Table 2.M.

Never try to place the motor coil assembly directly on the

magnet plates. Serious damage may result. Due to magnetic

attraction.

those responsible for the application and use of this motor assembly must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation, Anorad

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Anorad Corporation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT Identifies information that is critical for successful

application and understanding of the product.

Introduction

Using This Manual This motor manual is designed to help you install, integrate and start-up your

new Anorad Linear Motor. You do not have to be an expert in motion control.

However, this manual does assume you have a fundamental understanding of

basic electronics, mechanics, as well as motion control concepts and applicable

safety procedures.

The intent of this manual is to assist the user in the mechanical and electrical

installation of the Anorad LC Series Linear Motor.

Read this entire manual before you attempt to install your linear motor into

your motion system. Doing so will familiarize you with the linear motor

components and their relationship to each other and the system

After installation, check all system parameters to insure you have configured

your linear motor into your motion system properly.

Be sure to follow all instructions carefully and lastly but foremost pay special

attention to safety concerns.

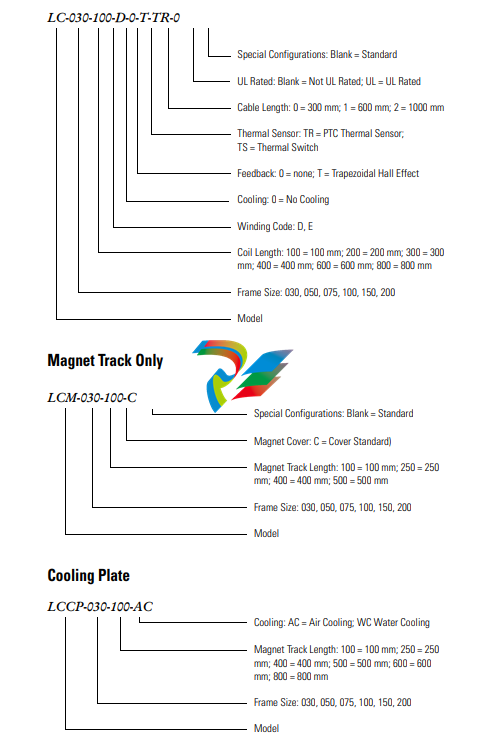

Product Description General

The LC Linear Motor Series is described in this section. Product features are

explored and the part numbering system is explained. This basic information

will help you develop an understanding of the linear motor’s basic

configuration. This configuration information is then used as the fundamental

understanding required to guide you through the rest of this manual.

Product Line Description

Anorad's LC Series of steel core linear motors represents the most advanced

linear motor technology available. The LC linear motor utilizes a unique patent

pending laminated steel core design. Coupled with the latest magnetic

materials and optimized by Finite Element Analysis (FEA), a very high force

density is achieved. The LC Linear Motors ares available in models with

continuous forces from 84.5 N to 5658 N, (19 lbf to 1272 lbf), and peak forces

from 195.7N to 9314 N, (44 lbf to 2094 lbf). Other frame sizes are available

with higher forces.

For servo drives that require commutation feedback, an optional trapezoidal

(digital) Hall effect feedback module may be attached to the front of the motor

coil. The LC may also be commutated via software. Anorad offers a full line of

compatible servo controls and drives.

Motor Features

• Steel core design for high force density

• Sinusoidal flux density and low-cog design yields smooth motion

• Robust design for heavy duty applications

• Modular magnet tracks permit unlimited travel

• Internal thermal sensor gives added motor protection

Maintenance Anorad linear motors require no maintenance when operated in a relative clean

environment. For operation in harsh and dirty environments minimal clean is

recommended every 6 months:

• Clean the metallic debris and other contaminants from the air gap. To

effectively remove the metal debris use a strip of masking tape.

Simply put a strip of tape on the magnet track an then remove it.

Keeping the magnet track clean will prevent witness marks. Witness

marks are caused by metal debris being dragged across the surface of

the stainless steel by the magnet field of the moving coil. Witness

marks have no effect on the performance of the motor.

Installation

Unpacking and Inspection Inspect motor assemblies to make certain no damage has occurred in

shipment. Any damage or suspected damage should be immediately

documented. Claims for damage due to shipment are usually made against the

transportation company. Also contact Anorad immediately for further advise.

Identify what options your linear motor is equipped with. Ensure the

information listed on the purchase order correlates to the information on the

packing slip that accompanied your motor components Verify that the quantity

of magnet plates received matches your job requirements. Inspect the

assemblies and confirm, if applicable, the presence of specified options.

ATTENTION

!

Linear Motors contain powerful permanent magnets which

require extreme caution during handling. When handing

multiple magnet plates do not allow the plates to come in

contact with each other. Do not disassemble the magnet

plates. The forces between plates are very powerful and can

cause bodily injury. Persons with pacemakers or Automatic

Implantable Cardiac Defibrillator (AICD) should maintain

a minimum distance of 12 inches from magnet assemblies.

Additionally, unless absolutely unavoidable, a minimum

distance of 5 feet must be maintained between magnet

assemblies and other magnetic/ferrous composite

materials. Use only non-metallic instrumentation when

verifying assembly dimension prior to installation (e.g.

calipers, micrometers, laser equipment, etc.)

Identifying the Linear Motor

Type

Coil Assembly (example)

1. Ensure the mounting surface to which the magnet plate is to be attached

is clear of any and all foreign material. If necessary, stone the mounting

surface (acetone or methanol may be applied as cleaning agent).

Do not clean the surface using abrasives!

4. Position the moving slide to the end of travel that you wish the cable to

exit. Making sure that the mounting face of the motor coil is clean and

free of burrs, install the motor under the slide. Select a M5 x 0.8 bolt

with a length that extends through the slide by 12 mm minimum, but

not more then 20 mm. Tighten snugly for now, bolts will be torqued

once installation is complete.

5. On the opposite end of the base, install the first magnet plate using M5

x 0.8 and 16 mm long SHCS. Non-magnetic tools and hardware

(beryllium copper, 300 series stainless steel, etc.) should be use. If not

available proceed with care since magnetic items will be attracted to the

magnet plates. Do not tighten bolts at this time. Install additional

magnet plates by placing them on the base and sliding towards the

previous install plate. Orient the plates such that the alignment holes are

toward the same side. This will ensure proper magnet polarity.

6. Move the slide, which you previously mounted motor coil to, over the

magnet plate. There may be some resistance while moving onto the

plate, this is normal. Measure the gap between the motor and magnet

using plastic shim stock. The gap should be 0.79 mm (0.031 in.) to

1.70 mm (0.067 in.). If gap is too large, add appropriate brass or stainless

steel shim between motor and slide. If gap is to small, machine the slide

or place shims under the bearing pucks.

7. Once the motor is gapped properly, install the remaining magnet plates.

8. The final alignment of the magnet plates are done with an aluminum

straight edge, and the alignment tool that was supplied with the magnet

plates. Slightly loosen the magnet plate mounting bolts, but not the ones

that are covered by the motor coil. Place the alignment tool in the holes

on each of the plates, this will properly position the pitch of the plates.

Align the edges of the plate with the aluminum straight edge and tighten

the bolts

9. Position the slide over the complete sections and continue aligning the

remainder of the plates.

10. If the area where the magnet plates are to be installed does not allow you

to use a straight edge describes above, an alternate method of aligning

plates can be done. Space the plate by using a 0.020 plastic shim between

the magnet plates, tighten the bolts, and then remove the shim.

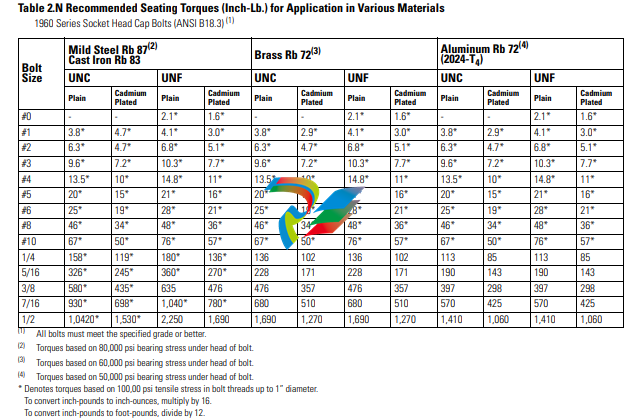

11. Once all the alignment is completed, torque all bolts to values listed in

the tables.When considering torque values for mounting hardware, take

into account the magnet plate, mounting surface and mounting

hardware. Per Table 2.N secure all assemblies in place using all

mounting holes.

ATTENTION

!

Remove alignment tool and make certain all magnet plate

mounting hardware is flush or below magnet surface to

prevent damage to the coil.

Motor/Hall Phasing and

Sequence

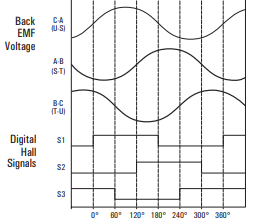

See Figure 2.15 for the standard phase and sequence relationship of the LC

series motors when phased in the specific motor direction. The Trapezoidal

Hall signals are used by a compatible three phase brushless servo drive to

perform electronic commutation. Two types of servo drive Hall-based

commutation techniques are possible, Trapezoidal Hall Mode and Encoder

(Software/Digital) Mode with Trapezoidal Hall start-up. Note: For optimal

commutation and force generation, the selected servo drive must be

compatible with the LC series phasing; and be wired to the motor correctly.

As shown in the phasing diagram:

S1 in phase with C-A Back EMF

S2 in phase with A-B Back EMF

S3 in phase with B-C Back EMF

Phase sequence = S1 leads S2 leads S3. Spacing is 120 degrees.

Figure 2.15 Motor Phasing Diagram

Back EMF Voltage vs. Hall Signals

Phasing direction = coil toward motor power cable or magnet assembly away

from power cable as shown in Figure 2.16.

ATTENTION

!

Incorrect Motor/Hall wiring can cause runaway conditions.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)