A-BPowerFlex 7000 Medium Voltage AC Drive Air-Cooled (’B’ Frame)—ForGe Control

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

About This Publication This document provides procedural information for managing daily or

recurring tasks involving the PowerFlex® 7000 medium voltage ‘B’ frame

drives (heatsink and heatpipe models).

Download Firmware, AOP,

EDS, and Other Files

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc.

Summary of Changes This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Who Should Use This

Manual

This manual is intended for use by personnel familiar with medium voltage

and solid-state variable speed drive equipment. The manual contains material

that enables regular operation and maintenance of the drive system.

What Is Not in This Manual This manual provides information specific to maintaining the PowerFlex 7000

‘B’ frame drive. This document does not include topics such as:

• Physically transporting or siting the drive cabinetry

• Installing or commissioning procedures

• Spare parts lists compiled for your order.

Rockwell Automation provides the site- and installation-specific electrical and

design information for each drive during the order process cycle. If they are

not available on site with the drive, contact Rockwell Automation.

If you have multiple drive types or power ranges, ensure you have the correct

documentation for each specific PowerFlex 7000 product:

• ‘A’ frame for lower-power air-cooled, configurations (up to

approximately 1250 hp/933 kW)

• ‘B’ frame for higher-power, air-cooled configurations (standard or

heatpipe models)

• ‘C’ frame for all liquid-cooled configurations

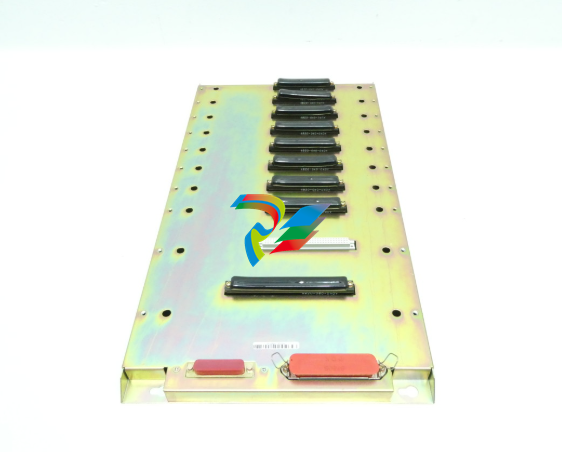

PowerFlex 7000 Drive Overview

The PowerFlex™ 7000 drive is a general-purpose, standalone, medium voltage

drive that controls speed, torque, direction, starting, and stopping of standard

asynchronous or synchronous AC motors. This drive works on numerous

standard and specialty applications such as fans, pumps, compressors, mixers,

conveyors, kilns, fan-pumps, and test stands in industries such as

petrochemical, cement, mining and metals, forest products, power generation,

and water/waste water.

The PowerFlex 7000 drive meets most common standards from these

organizations:

• National Electrical Code (NEC)

• International Electrotechnical Commission (IEC)

• National Electrical Manufacturers Association (NEMA)

• Underwriters Laboratories (UL)

• Canadian Standards Association (CSA).

The drive is available with the world’s most common supply voltages at

medium voltage, from 2400…6600V. The design focuses on high reliability,

ease of use, and lower total cost of ownership.

Topology The PowerFlex 7000 drive uses a pulse width modulated (PWM) – current

source inverter (CSI) topology. This topology applies to a wide voltage and

power range. The power semiconductor switches used are easy-to-series for

any medium voltage level. Semiconductor fuses are not required for the power

structure due to the current limiting DC link inductor.

With 6500V PIV rated power semiconductor devices, the number of inverter

components is minimal. For example, only six inverter switching devices are

required at 2400V, 12 at 3300…4160V, and 18 at 6600V.

The PowerFlex 7000 drive also provides inherent regenerative braking for

.png)