A-BPowerFlex 4 and 40 AC Drives

Product Overview

Providing users with powerful motor speed control in a compact, space saving design, the Allen-Bradley® PowerFlex® 4 and

40 AC drives are the smallest and most cost-effective members of the PowerFlex® family of drives. Available in power ratings

from 0.2 to 11 kW (0.25 to 15 HP) and in voltage classes of 120, 240, 480 and 600 volts, PowerFlex 4 and 40 are designed

to meet global OEM and end-user demands for flexibility, space savings, ease of use and are cost-effective alternatives for

speed control of applications such as machine tools, fans, pumps and conveyors and material handling systems

Packaging and Mounting

• Installation can be a virtual snap using the DIN rail mounting feature on

A and B frame drives. Panel mounting is also available, providing added

flexibility.

• Flange mount drives are available to reduce overall enclosure size.

• Zero Stacking™ is allowable for ambient temperatures up to 40 °C, saving

valuable panel space. 50 °C ambient temperatures are permitted with

minimal spacing between drives.

• Integral filtering is available on all 230V single phase ratings, providing a

cost-effective means of meeting EN55011, Class A and B EMC

requirements. External filters provide compliance to Class A and B

requirements for all PowerFlex 4 and 40 ratings.

• An optional IP30, NEMA/UL Type 1 conduit box is easily adapted to

the standard IP20 (NEMA Type Open) product, providing increased

environmental ratings.

• IP66, NEMA/UL Type 4X/12 (Indoor) for mounting directly in the

product environment. Listed by UL to resist dust, dirt, etc. and survive

high pressure water spray. Also certified by NSF to ensure conformity

with international food equipment standards.

Start Up, Programming and Operation

• An integral keypad provides out of the box operation using the local

potentiometer and control keys.

• The 10 most common application parameters are contained in the Basic

Program Group, making programming fast and easy.

• The programming keys have the same function as all other PowerFlex

drives, so if you can program one PowerFlex drive, you can program them

all.

• 4 digit display with 10 additional LED indicators provides an intuitive

display of drive status and information.

• Integral RS-485 communications can be used for programming from a

PC. It can also be used in a multi-drop network configuration. A serial

converter module provides connectivity to any controller with a DF1

port.

• A NEMA/UL Type 4X remote and NEMA/UL Type 1 hand-held

LCD keypad provide additional programming and control flexibility,

both featuring the popular CopyCat function

Optimized Performance

• Removable MOV to ground provides trouble-free operation when used on ungrounded

distribution systems.

• A relay pre-charge limits inrush current.

• Integral brake transistor, available on all ratings (except no brake version), provides

dynamic braking capability with simple low cost brake resistors.

• DIP switch settable 24V DC sink or source control for control wiring flexibility.

• 150% overload for 60 seconds or 200% overload for 3 seconds provides robust overload

protection.

• Adjustable PWM frequency up to 16 kHz ensures quiet operation.

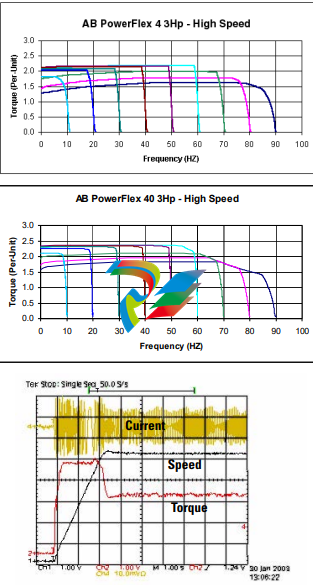

Sensorless Vector Performance

PowerFlex 4

• Drive automatically provides auto boost (IR

compensation) and slip compensation.

• Provides excellent speed regulation and high levels of

torque across the entire speed range of the drive, and

improved speed regulation even as loading increases.

Sensorless Vector Control

PowerFlex 40

• Sensorless Vector Control provides exceptional speed

regulation and very high levels of torque across the

entire speed range of the drive.

• The Autotune feature allows the PowerFlex 40 to adapt

to individual motor characteristics.

Performance

• This graph depicts the ability of a PowerFlex 40 drive to

accelerate into at least 150% load. A PowerFlex 4 will

perform similarly, but with a slightly higher acceleration

time.

• At 100% motor load, the drive will run the motor at

synchronous speed.

• Excellent current regulation.

• Linear acceleration.

• Best in class digital input response time and

repeatability

Performance

• Sensorless Vector Control develops high torque over a wide speed range

and adapts to individual motor characteristics.

• Variable PWM allows the drive to output more current at low

frequencies.

• Integral PID functionality enhances application flexibility.

• Timer, Counter, Basic Logic and StepLogic™ functions can reduce

hardware design costs and simplify control schemes.

– Timer function: Relay or opto outputs controlled by drive

performing timer function. Timer is initiated by activating a digital

input programmed as “Timer Start.”

– Counter function: Relay or opto outputs controlled by drive

performing counter function. Counter function is activated by a

digital input programmed as “Counter Input.”

– Basic Logic: Relay or opto outputs controlled by status of digital

inputs programmed as “Logic Inputs.” Performs basic Boolean logic.

.png)