A-BPowerFlex 4 and 40 AC Drives

– StepLogic: Logic-based steps using preset speed settings. Each step

can be programmed for a specific speed, direction and accel/decel

profile. Drive outputs can be used to indicate which step is being performed.

I/O

• Two (2) Analog Inputs (one unipolar and one bipolar) are

independently isolated from the rest of the drive I/O. These inputs

can be toggled between via a digital input.

• Three (3) fixed and four (4) fully programmable Digital Inputs

provide application versatility.

• One (1) Analog Output is DIP switch selectable for either

0…10V or 0…20mA. This scalable, 10-bit output is suitable for

metering or as a speed reference for another drive.

• Two (2) Opto Outputs and one (1) form C relay output can be

used to indicate various drive, motor or logic conditions.

Communications

• Integral communication cards such as DeviceNet™, EtherNet/IP™,

PROFIBUS™ DP, LonWorks® and, ControlNet™ can improve machine

performance.

• The DSI Wireless Interface Module (WIM) provides a wireless

communication interface between a Pocket PC, laptop computer or

desktop computer equipped with Bluetooth® wireless technology, and any

Allen-Bradley® product supporting the DSI™ protocol.

• Field installed option allows for future addition of stand-alone drives to a

network.

• Online EDS file creation with RS NetWorx™ providing ease of set-up on a

network.

Versatile Programming and Network Solutions

• PowerFlex 4 and PowerFlex 40 are compatible with

any device that acts as a RTU Master and supports

standard 03 and 06 RTU commands.

• A network can be configured using PowerFlex 40

drives with optional communication cards for high

performance and flexible configuration capabilities.

– BACnet

– ControlNet

– DeviceNet

– EtherNet/IP

– LonWorks

– PROFIBUS DP

• A multi-drive solution can be reached using a single

PowerFlex 40 DeviceNet option, with the ability for

up to five drives to reside on one node.

• Integral RS485 communications enable the drives to

be used in a multi-drop network configuration. A

serial converter module (SCM) provides connectivity

to any controller with a DF1 port. The SCM can be

eliminated if the controller acts as a RTU Master.

PC Programming Software

Through the use of a Serial Converter Module and

DriveExplorer™ or DriveTools™ SP software,

programming can be greatly simplified.

DriveExplorer Software

• View and modify drive and adapter parameters in

a method similar to the file management capability

of Microsoft Windows Explorer.

• Operate the drive via an on-screen Control Bar,

which is a tool that allows you to start, stop, and

change the speed reference of the drive.

• Save, restore and print parameter information.

• Compare current parameters with factory defaults

or previously saved parameter values.

• Edit, upload and download parameters.

DriveTools SP Software

• Online and offline programming capability

• In-grid and dialog-based parameter editing

• Immediate visual indication of drive and communication status when viewing online drive

• Integrated HTML Help architecture

Installation Considerations

PowerFlex 4 and 40 drives have the following built in protective features to help simplify installation.

• Ground fault protection while starting and running ensures reliable operation

• Electronic motor overload protection increases motor life

• Removable MOV to ground ensures compatibility with ungrounded systems

• 6kV transient protection provides increased robustness for 380…480V system voltages

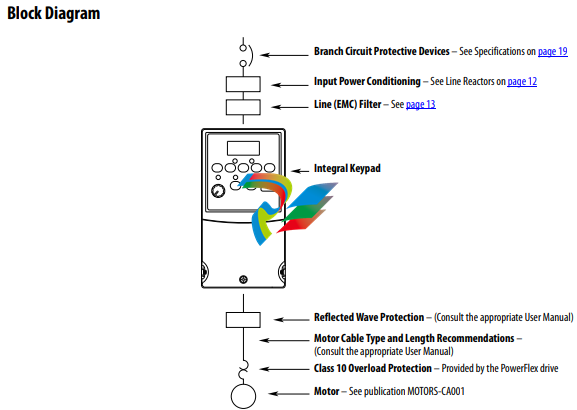

There are many other factors that must be considered for optimal performance in any given application. The block diagram

below highlights the primary installation considerations. Consult the PowerFlex 4 or PowerFlex 40 User Manual,

Publications 22A-UM001 or 22B-UM001 available online at www.rockwellautomation.com/literature, for detailed

recommendations on input power conditioning, CE conformance (EMC filtering), dynamic braking, reflected wave

protection, motor cable types and motor cable distances.

Control Wiring

PowerFlex 4

• The control logic is 24V DC and can be set for either

Sink or Source control via a DIP switch setting.

• Control terminal screws are sized for a conventional

blade screw driver.

• I/O Terminals 1, 2 and 3 are dedicated for Stop, Start

and Reverse operation respectively. These I/O

Terminals can be programmed for 2- or 3-Wire

operation to meet application requirements.

• I/O Terminals 4 and 5 are programmable and provide

added flexibility. Programmable functions include:

– Local Control

– Preset Frequencies

– Jog

– RS485 Control

– Second Accel/Decel

– Auxiliary Fault

– Clear Fault

• Speed can be controlled via a 0…10V input or 4…20

mA input. Both are electrically isolated from the drive.

• One form C relay can be programmed to provide the

status of a wide variety of drive conditions.

• The drive is shipped with a jumper installed between

I/O Terminals 01 and 11 to allow out of box operation

from the keypad.

PowerFlex 40

• The control logic is 24V DC and can be set for either

.png)

.png)