A-BPowerFlex 7000 Medium Voltage AC Drive Air-Cooled (’B’ Frame)—ForGe Control

applications where the load is overhauling the motor, or where high inertia

loads are quickly slowed down. The drive uses the following:

• Symmetrical gate commutated thyristors (SGCTs) for machine converter

switches

• SGCTs for active front-end (AFE) rectifier configurations for the line

converter switches

• Silicon-controlled rectifiers (SCRs) for 18-pulse rectifier configurations

The PowerFlex 7000 drive provides a selectable option for enhanced torque

control capabilities and increased dynamic control performance. This highperformance torque control (HPTC) feature delivers 100% torque at zero speed

and provides torque control through zero speed with smooth direction

transition.

Rectifier Designs Configurations

The PowerFlex 7000 drive offers three rectifier configurations for ‘B’ frame

drives:

• Direct-to-Drive™ (AFE rectifier with integral line reactor and CMC)

• AFE rectifier with separate isolation transformer

• 18-pulse rectifier with separate isolation transformer

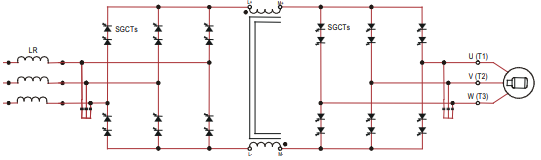

Direct-to-Drive

Direct-to-Drive technology does not require an isolation transformer or

multiple rectifier bridges as in voltage source inverter (VSI) topologies offered

by others. The approach is completely different. Instead of multiple

uncontrolled rectifiers, a single AFE rectifier bridge is supplied. The rectifier

semiconductors that are used are SGCTs. Unlike the diodes that are used in

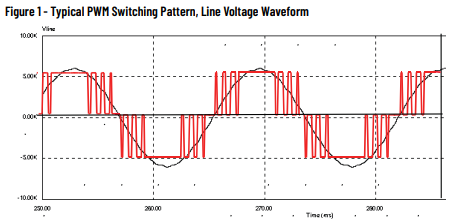

VSI rectifier bridges, SGCTs are turned on and off by a gating signal. A PWM

gating algorithm controls the firing of the rectifier devices, similar to the

control philosophy of the inverter. The gating algorithm uses a specific

42-pulse switching pattern called selective harmonic elimination (SHE) to

mitigate the 5th, 7th, and 11th harmonic orders

A small integral line reactor and capacitor addresses the high harmonic orders

(13th and above) and provides virtually sinusoidal input voltage and current

waveforms back to the distribution system. This configuration delivers

excellent line-side harmonic and power factor performance to meet IEEE 519-

1992 requirements and other global harmonic standards in virtually all cases.

This setup also provides a simple, robust power structure that maximizes

uptime by minimizing the number of discrete components and the number of

interconnections required.

A CMC mitigates the common mode voltage seen at the motor terminals, so

standard (non-inverter duty rated) motors and motor cables can be used. This

technology is ideal for retrofitting existing motor applications

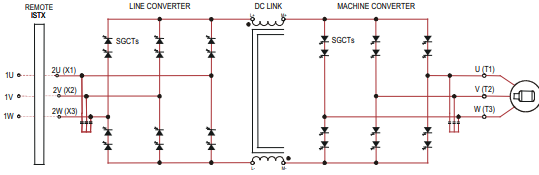

AFE Rectifier with Separate Isolation Transformer

For applications when the line voltage is higher than the motor voltage, a

transformer is required for voltage matching. In this case, providing an AFE

rectifier with a separate isolation transformer is ideal (indoor and outdoor

transformer versions are offered). The isolation transformer replaces the

requirement for an integral line reactor and replaces the requirement for a

CMC that is supplied in the Direct-to-Drive rectifier configuration. However,

the AFE rectifier, its operation, and advantages are the same as the Direct-toDrive configuration.

Figure 3 - 3300/4160 AFE Rectifier with Separate Isolation Transformer

For high power constant torque applications and/or when the line voltage is

higher than the motor voltage, a transformer is required for voltage matching

(indoor and outdoor transformer options are available). The 18-pulse rectifier

uses SCRs instead of the SGCTs used for an AFE rectifier. When used for high

power constant torque applications, the 18-pulse rectifier has lower losses than

the AFE rectifier, making 18-pulse ideal for the highest power requirements.

The 18-pulse isolation transformer provides the required input impedance and

addresses common mode voltage just like the separate isolation transformer

used with the AFE rectifier. However, instead of a PWM rectifier switching

pattern and a single rectifier bridge, the 18-pulse configuration mitigates line

side harmonics through harmonic current cancellation in the isolation

transformer phase shifted secondary windings. The inverter is the same

configuration for all available rectifier options.

Figure 4 - 3300/4160V 18-pulse Rectifier with Separate Isolation Transformer

Cooling Technology These VFDs are supplied with heatsinks for most configurations and heatpipes

for the highest-power AFE configurations. While both configurations draw

heat away from the semiconductors, heatpipes are bigger, more efficient, and

require larger fans and airflow.

Information and graphics in this manual show both configurations.

Motor Compatibility The PowerFlex 7000 drive achieves near-sinusoidal current and voltage

waveforms to the motor, resulting in no significant additional heating or

insulation stress. Temperature rise in the motor connected to the VFD is

typically 3 °C (5.5 °F) higher compared to across-the-line operation. Voltage

waveform has dv/dt of less than 50 V/μs. The peak voltage across the motor

.png)