ABBDCS800 Quick guide DCS800 Drives (20 A to 5200 A)

VDE 0100 and IEC 664 or DIN/VDE 0110 and national accident

prevention rules!).

For the purposes of these basic safety instructions, “skilled

technical personnel” means persons who are familiar with the

installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance

of their functions.

2. Intended use

Drive converters are components designed for inclusion in electrical installations or machinery.

In case of installation in machinery, commissioning of the drive

converter (i.e. the starting of normal operation) is prohibited until

the machinery has been proved to conform to the provisions of

the directive 89/392/EEC (Machinery Safety Directive - MSD).

Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal opertion) is admissible

only where conformity with the EMC directive (89/336/EEC) has

been established.

The drive converters meet the requirements of the low-voltage

directive 73/23/EEC. They are subject to the harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with

EN 60439-1/ VDE 0660, part 500, and EN 60146/ VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate and from the

documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be

complied with.

The climatic conditions shall be in conformity with prEN 50178.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent documentation.

The drive converters shall be protected against excessive

strains. In particular, no components must be bent or isolating

distances altered in the course of transportation or handling. No

contact shall be made with electronic components and contacts.

Drive converters contain electrostatic sensitive components

which are liable to damage through improper use. Electric

components must not be mechanically damaged or destroyed

(potential health risks).

5. Electrical connection

When working on live drive converters, the applicable national

accident prevention rules (e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance with

the relevant requirements (e.g. cross-sectional areas of conductors, fusing, PE connection). For further information, see documentation.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters and wiring,

are contained in the drive converter documentation. They must

always be complied with, also for drive converters bearing a

CE marking. Observance of the limit values required by EMC

law is the responsibility of the manufacturer of the installation or

machine.

6. Operation

Installations which include drive converters shall be equipped

with additional control and protective devices in accordance with

the relevant applicable safety requirements, e.g. Act respecting

technical equipment, accident prevention rules etc. Changes

to the drive converters by means of the operating software are

admissible.

After disconnection of the drive converter from the voltage

supply, live appliance parts and power terminals must not be

touched immediately because of possibly energized capacitors.

In this respect, the corresponding signs and markings on the

drive converter must be respected.

During operation, all covers and doors shall be kept closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

Keep safety instructions in a safe place!

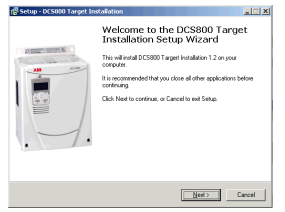

Installing the DCS800 PC tools on Your computer

After inserting the DCS800 CD all programs and documentation

necessary to work with the DCS800 will be automatically installed.

This includes:

1. DriveWindow Light for parameterization, commissioning and

service

2. Hitachi FDT 2.2 for firmware download

3. Installation CD of DCS800 Drive for e.g. DWL Wizard, ABB

documents

4. CoDeSys for 61131 application programming

Attention:

If You do not want to install a certain program just skip it by using

Cancel at the beginning of the program’s wizar

If the installation routine does not start automatically:

- Go to Start/Run and browse for setup.exe on the CD. Now start

the installation by confirming with OK

- Compact installtion for DriveWindow Light + Commsioning

Wizard + DriveWindow Light AP is reccomended

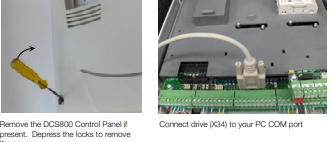

Steps to connect Drive to PC

• The documentation can be found under

C:ABBDCS800Docu

• Remove design cover from the converter module

• Start DriveWindow Light PC tool

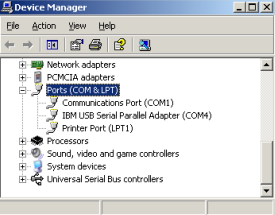

Check the communication setting of your COM port

If You use USB to COM port interface or PCMCIA / COM adapters double check the active COM enabled

Start => Settings => Control Panel => System => Hardware

=> Device Manager

COM address of USB interface can change after the next boot