Product Overview

Revolutionary Vision Inspection Technology

The RELIANCE INSPECTOR VCIB-06 represents the pinnacle of industrial vision inspection systems, combining cutting-edge optical technology with advanced AI-powered analysis capabilities to deliver unparalleled quality control and defect detection across manufacturing environments.

🔍 High-Resolution Imaging

Features a 12-megapixel CMOS sensor with advanced lens optics, capable of detecting defects as small as 0.1mm with exceptional clarity and precision.

🤖 AI-Powered Analysis

Integrated machine learning algorithms provide real-time defect classification and quality assessment, reducing false positives by up to 95%.

⚡ Lightning-Fast Processing

Process up to 200 parts per minute with sub-millisecond response times, ensuring seamless integration into high-speed production lines.

🌐 Industry 4.0 Ready

Built-in connectivity options including Ethernet, USB 3.0, and wireless protocols for seamless integration with existing manufacturing systems.

Technical Specifications

| Parameter | Specification | Details |

|---|---|---|

| Image Sensor | 12MP CMOS | 4000 × 3000 pixels, Global Shutter |

| Lens System | Variable Focus | 8-50mm, F1.4-F16, Auto/Manual Focus |

| Inspection Speed | 200 PPM | Parts Per Minute (typical) |

| Detection Accuracy | 0.1mm | Minimum defect size detection |

| Processing Power | ARM Cortex-A78 | Quad-core 2.2GHz with GPU acceleration |

| Memory | 8GB RAM / 128GB Storage | Expandable via SD card |

| Connectivity | Multiple Interfaces | Ethernet, USB 3.0, Wi-Fi, Bluetooth |

| Operating Environment | Industrial Grade | -10°C to +60°C, IP65 Protection |

| Power Requirements | 24V DC | Power consumption: 35W typical |

| Dimensions | 220 × 150 × 95mm | Compact industrial housing |

Industry Applications

🏭 Automotive Manufacturing

Application: Quality inspection of automotive components including engine parts, body panels, and electronic assemblies.

Benefits: Ensures zero-defect delivery to assembly lines, reduces warranty claims, and maintains brand reputation through consistent quality control.

💊 Pharmaceutical Production

Application: Inspection of tablet integrity, capsule filling verification, and packaging quality control with FDA compliance.

Benefits: Maintains pharmaceutical standards, prevents contaminated products from reaching market, and ensures regulatory compliance.

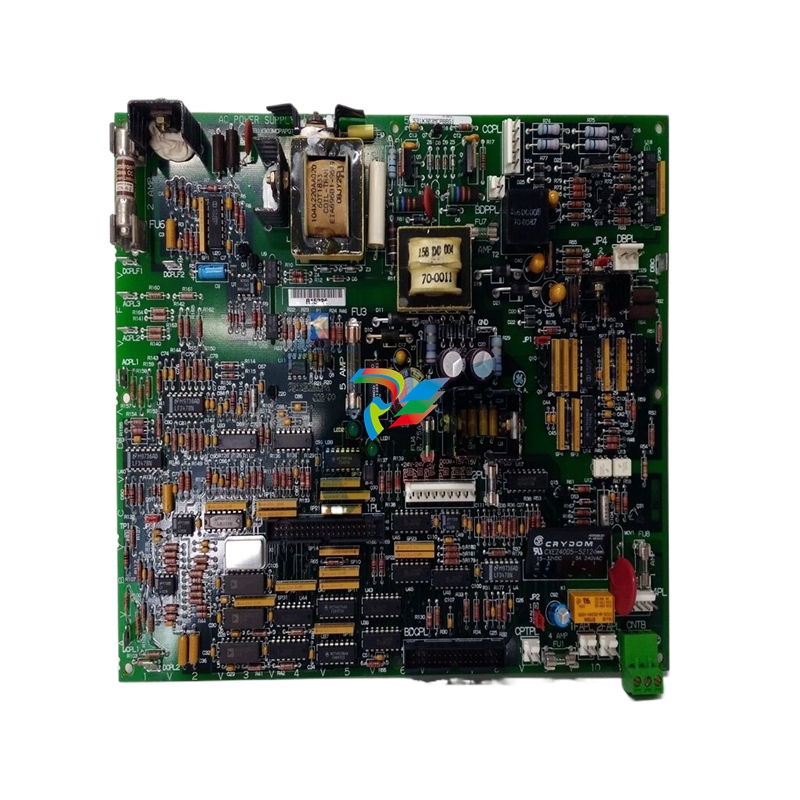

📱 Electronics Assembly

Application: PCB inspection, component placement verification, solder joint quality assessment, and surface mount technology validation.

Benefits: Reduces field failures, improves product reliability, and minimizes costly recalls in consumer electronics.

🥫 Food & Beverage Industry

Application: Package integrity inspection, label verification, fill level monitoring, and contamination detection.

Benefits: Ensures food safety standards, reduces product recalls, and maintains consumer trust through consistent quality.

🔧 Precision Manufacturing

Application: Dimensional measurement, surface finish inspection, and geometric tolerance verification for precision components.

Benefits: Maintains tight tolerances, reduces scrap rates, and ensures interchangeability of precision parts.

🏗️ Heavy Industry

Application: Weld quality inspection, structural component verification, and safety-critical part validation.

Benefits: Ensures structural integrity, prevents catastrophic failures, and maintains safety standards in critical applications.

VCIB Series Model Comparison

VCIB-04

Entry Level

• 8MP Sensor

• 150 PPM Speed

• Basic AI Features

• Ethernet Connectivity

• Ideal for small-scale operations

VCIB-05

Standard

• 10MP Sensor

• 175 PPM Speed

• Enhanced AI Algorithms

• Multiple Connectivity Options

• Balanced performance and cost

VCIB-06

Premium (Current Model)

• 12MP Sensor

• 200 PPM Speed

• Advanced AI with Deep Learning

• Full Connectivity Suite

• Maximum performance and features

VCIB-07

Next Generation (Coming Soon)

• 16MP Sensor

• 250 PPM Speed

• Neural Network Processing

• 5G Connectivity

• Future-ready technology

Why Choose VCIB-06?

The VCIB-06 strikes the perfect balance between cutting-edge technology and proven reliability. With its advanced AI capabilities, high-speed processing, and comprehensive connectivity options, it's the ideal choice for manufacturers looking to implement state-of-the-art quality control systems without compromising on performance or reliability.

Technical Implementation

Advanced Optics System

The VCIB-06 employs a sophisticated optical system featuring telecentric lenses with minimal distortion, ensuring accurate measurements across the entire field of view. The system includes programmable LED lighting with multiple wavelengths for enhanced defect visibility.

Machine Learning Engine

Built-in deep learning algorithms can be trained on-site for specific applications. The system supports transfer learning, allowing rapid adaptation to new product types with minimal training data, significantly reducing setup time.

Real-time Processing

Dedicated image processing hardware enables real-time analysis without compromising inspection speed. The system can simultaneously process multiple images while maintaining consistent throughput rates.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)