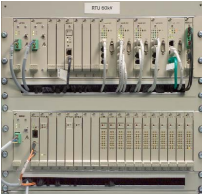

Remote Terminal Unit RTU560

• Archive features to provide process data availability over longer periods for recovering or decoupling,e.g.the storing of disturbance files recorded by protection relays in an archive and analyzing them later,after transferring them to an Office PC

• Communication with multiple Network Control Centers (NCC).of process data filtering according to the demands of the NCC.Possible with different telecontrol protocols for each NCC

• Extended diagnosis functionality of the RTU equipment to reduce the costs for problem analysis and maintenance by accessing the information via Internet or Intranet options. This should be possible independent of the directly connected telecontrol links

• Interfacing various types of IEDs,such as digital protection relays or new transducers via fieldbus interfaces,etc

• Flexibility and space for future demands to extend the RTU for additional installed primary process units and/or higher demands in terms of control The architecture of a telecontrol system must be designed in such a way that it,thanks to its modularity and flexibility,can be adapted to the conditions and sizes of the different stations.It should also be open for later extensions of any type.

Our Solution for different Applications – the RTU560

ABB´s solution to different application requirements is the Remote Terminal Unit system RTU560. A key feature of the RTU560 concept is the extended possibility to integrate the various communication demands in a highly flexible and cost-optimized way.The capability of RTUs has increased significantly over the last few years.This has provided the opportunity to use remote terminal units for different applications.The RTU560 uses the same components to provide specific functions for the different applications.Since all applications are served out of the same product family a future upgrade to a different application is always possible. This goes in line with the ABB strategy to reuse I/O modules of ABB RTUs 200/232 for upgrading to RTU560. The various functional requirements can be grouped to the following three applications:

• Remote Control

• Communication Gateway

• Station Automation

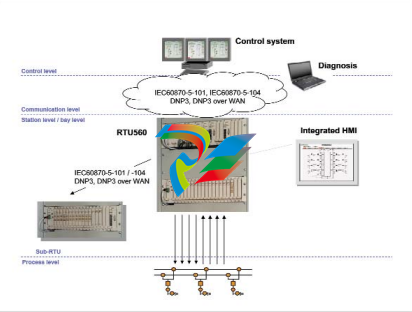

Remote Control One of the main tasks of the remote control application is the data collection

of hard wired information and provision of those to a higher level Control System. The RTU560

uses multi processor architecture to achieve high performance data processing. The scalable pl

atform,together with the modular IO-components guarantee the highest flexibility for different s

ignal appearance.The direct binary IO-interface for up to 110-220 V DC requires no additional int

erposing relays. The demand to communicate to various sub RTUs, IEDs and control centers is c

overed by the highly advanced communication capabilities.PLC-Functions according to IEC 611

31-3 enable the user to get automation functionality without using an additional product.

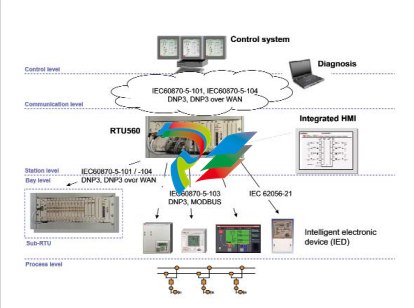

Communication Gateway The RTU560 with its highly sophisticated communication capabilities can also

be used as a communication gateway. By using TCP/IP networks and decentralized station communica

tion gateways,the complex frontend structures can be simplified. Shifting of centralized communicatio

n functions to station level utilizes the available bandwidth more efficiently and reduces the required c

ommunication lines at the same time. High availability is a common requirement today. The RTU560 a

ccommodates this with its decentralized structure compared to PCs or workstations. The flexible redu

ndancy concepts support different levels.The system approach of the RTU560 allows having redunda

nt power supplies,redundant communication lines and redundant communication modules accordin

g to the customer specific demand.A combination of the various redundancies is also possible.

For communication gateways,minimal engineering and implementation of standard and non standard protocols is crucial. The RTU560 with its open architecture and user friendly tools satisfies these requirements.

Station Automation The station automation application consists of interfaces to a mixture of protection and control equipment as well as metering devices and other automation products.The Human Machine Interface integrated into the RTU560 allows a basic local control and monitoring. Transmission of disturbance records and load profiles by using the communication network of the RTU560 are also available functions

Benefits:

• Cost optimized station automation with IEC 60870-5-103

• Data engineering for RTU and HMI in one step

• Use of the RTU560 communication network for disturbance data and load profiles

• Retrofit with digital bay controllers possible step by step

Flexible System Concept

The software and hardware concept is based on modularity. The software application tasks can be organized in such a way as to be distributed over different communication units (CMU boards). This is possible due to an internal communication concept that keeps all CMU boards informed about the contents of the process data interface. There is one process and system database which is available in adapted copies for each CMU board. The internal communication system ensures that all process data are consistent. The different CMU boards run the communication tasks for the connected serial links. This allows the type and number of different communication links running on one CMU board to be defined.System performance is defined by the configuration of the CMU boards.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)