Remote Terminal Unit RTU560

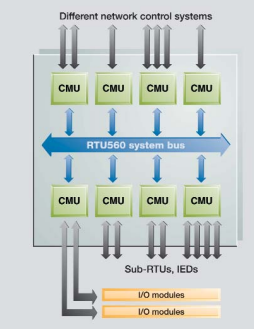

The RTU560 is able to communicate with different hierarchical levels of a network control system, with subordinated RTUs or any other intelligent electronic devices (IEDs),or with the test and diagnostic system. The most important standard protocols supported by RTU560 for communication with the control system are:

• IEC 60870-5-101

• IEC 60870-5-104

• DNP 3.0 (also on ethernet)

• Modbus • RP 570/71

• Indactic 23/ 33/ 35

• TG 800 • Sinaut 8FW

• Conitel 300 For communication with subordinated RTUs and IEDs such as protection relays,local control units,etc.,the following protocols,among others,are available:

• IEC 60870-5-101

• IEC 60870-5-102

• IEC 60870-5-103

• IEC 60870-5-104

• DNP 3.0 • SPA-Bus

• Modbus

• RP570/71

• Indactic 21 The connection of the respective communication lines can be carried out in several ways:

• Direct links with RS 232-C interfaces (local communication)

• Voice-frequency telegraphy over leased telecommunication lines,private lines with narrow bandwidth modems or power line carriers

• Radio links

• Dial-up modem

• Fiber-optic cables

• Digital communication networks

With this concept the RTU560 fulfills the highest availability requirements. Technical features

• Redundant communication lines or links; communication via 2 communication lines in a parallel mode (multi host with all available protocols) or in an active/standby switchover mode (redundant line/network with IEC 60870- 5-101/104)

Time Synchronization The accuracy and resolution of the time stamp for a process event is important for analysing a process disturbance,especially when it is necessary to analyse events from and between different stations. The RTU560 meets this requirement.The internal time management is controlled by the CMU communication boards. The time resolution of the RTU560 is 1 ms for events,scanned by the directly connected I/O boards.Synchronization with absolute time can be achieved by one of the following four methods:

• Time synchronization by the network control center (NCC) via a periodically transmitted synchronization instruction with a communication protocol supporting this function

• Time synchronization using a real-time clock that receives the date and time from the GPS system

• Time synchronization using a real-time clock that receives date and time information from the DCF 77 time standard

• Time synchronization using SNTP V4 (RFC2030) on a LAN/WAN network The RTU560 time management system synchronizes the RTU with the supplied absolute time with a high degree of accuracy.The absolute accuracy is mainly provided by the source for synchronization used,whereby GPS and DCF 77 allow an accuracy of 5 ms and better.The accuracy of time synchronization by the NCC depends on transmission speed,and the method used within the NCC A time synchronized RTU560 can synchronize subordinate RTUs and IEDs via:

• a periodically transmitted synchronization instruction with a communication protocol supporting this function

• Time synchronization using SNTP V4 (RFC2030) on a LAN/WAN network Special hardware and software logic with a high control quality has been incorporated on each of the CMU communication boards to manage real time within the RTU560.Once the RTU560 is synchronized,the RTU560 can maintain a time accuracy of about 2 PPM,even if the time synchronization source is lost for a certain period.

Benefits:

• Excellent reliability in performance and communication

• High reliable remote control of important substations

• Reduction of service and maintenance cost

• Scalable redundancy and cost optimized concepts

Benefits:

• Flexible adaptation of time synchronization to system circumstances

• High time accuracy over the total network

RTU560 web server

Integrated Human Machine Interface For basic local monitoring and basic control an Human Machine Interface was integrated into the RTU560. The HMI-functionality itself is an integrated part of the RTU560 functionality;no additional SCADA product is needed.Single line pictures with active monitoring and control elements are stored on the CMU of the RTU560. Event and alarm lists are also available and exportable as CSV format for documentation. The data of the lists are stored on the flash which makes it power failure proof. The only software requirement for visualization on a PC is the Java Virtual Machine Freeware. The single line diagram allows an instant overview of the substation. The picture editor has a symbol library with predefined dynamic symbols. The picture editor contains different language and character sets. The component editor enables the user to create customer specific symbols in case they are not available in the standard libraries. The editor allows easy linking of dynamic symbols to the RTU560 runtime data to prevent engineering faults.Access authority for different users or groups together with command authority is essential for secure operation. Therefore this feature is also an integrated component of the RTU560.

.png)

.png)

.png)