Remote Terminal Unit RTU560

n. The Engineering principle in RTUtil 560 is according to IEC 613

46-1 standard.With the RTUtil 560, separate views for signals,hardware,and communic

ation data is possible.This makes configuration changes easy.Before generating configurat

ion files, the RTUtil 560 system carries out an engineering data consistency check. Any engi

neering errors occurring will be recognized and logged

in files with the error location. The configuration file transfer will be done by using the integra

ted web server connected to the RTU560 MMI interface. The configuration of the RTU560 can a

lso be carried out from a remote PC via Internet links or the customer's Intranet. Download by a n

etwork control center via IEC 60870-5-101/104 file transfer protocol is also possible.Upload of the data files is used for reverse data engineering

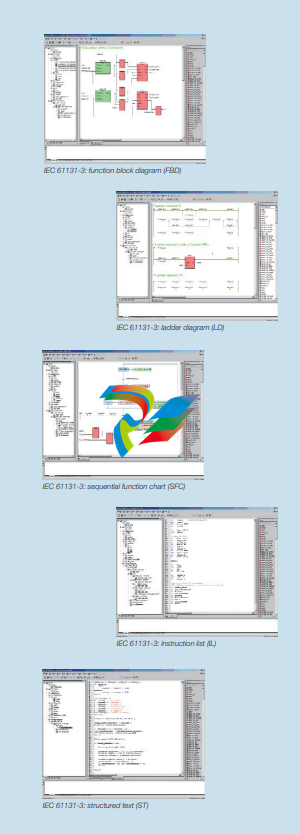

The RTU560 can optionally be equipped with a Programmable Logic Control (PLC) software package. This allows sequential control or closedloop application functions that are processed in parallel to the telecontrol activities. The PLC programming package fully complies to the IEC 61131-3 programming standard. The modularity of the RTU560 in hardware and software allows PLC programs to be run either on the same CMU central board,parallel to the telecontrol task, or on a separate CMU central board used only for the PLC application.PLC programs have access to all process signal values as well as the process signal qualifiers such as invalid,time,etc..PLC programs running distributed applications may use the qualifiers for secure and safe operation. PLC programs update the process signal values via the process data interface. The telecontrol task will be informed about changes and updates the new output values either to the process output boards or via the communication line to the network control centers and subdevices. PLC programs are developed by a powerful PLC programming tool MULTIPROG® wt. The PLC package allows programming in the programming languages defined in IEC 61131-3:

• Function Block Diagram (FDB)

• Ladder Diagram (LD)

• Sequential Function Chart (SFC)

• Instruction List (IL)

• Structured Text (ST) The function block RTU library contains function blocks to interface with the process I/Os values, attributes and qualifiers. Additionally it is also possible to create user-specific function blocks or functions for various applications.

Benefits:

• No need of additional PLC systems

• Flexible method to adapt to customer specific requirements

• Reduced education cost due to compatibility to IEC 61131-3 programming standard

.png)

.png)

.png)