Electro-Pneumatic Positioner TZIDC, TZIDC-1x0, TZIDC-2x0

1.4 Target groups and qualifications

Installation, commissioning, and maintenance of the product may only be performed by trained specialist personnel who have been authorized by the plant operator to do so. The specialist personnel must have read and understood the manual and comply with its instructions. Prior to using corrosive and abrasive materials for measurement purposes, the operator must check the level of resistance of all parts coming into contact with the materials to be measured. ABB Automation Products GmbH will gladly support you in selecting the materials, but cannot accept any liability in doing so. The operators must strictly observe the applicable national regulations with regards to installation, function tests, repairs, and maintenance of electrical products.

1.5 Explosion protection

Depending on the type of explosion protection, one of the following name plates is attached to the left of the positioner beside the main name plate. It shows the explosion protection and the unit's relevant EX certificate. More detailed information about the device can be found under "Certificates" in the appendix to the operating instructions.

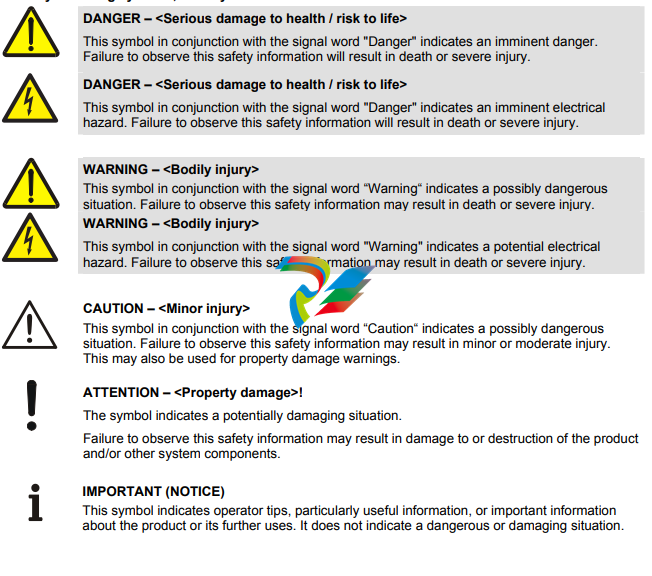

Warning - General risks!

Observe the units' relevant technical data and special conditions in accordance with the applicable certificate.

The positioner has two operating levels: Operating level On the operating level the positioner operates in one of four possible operating modes (two for automatic control and two for manual mode). Parameters cannot be changed or saved on this level. Configuration level On this level most of the parameters of the positioner can be changed locally. The PC is required to change the limit values for the movement counter, the travel counter, and the userdefined characteristic curve.

Caution - Risk

During external configuration via a PC, the positioner no longer responds to the setpoint current. Prior to external configuration, always move the actuator to the safe position and activate manual adjustment.

To simplify operation, the parameters have been categorized into parameter groups through which you can navigate by means of push buttons (see the section titled "Displays and operating elements"). On the configuration level the active operating mode is deactivated. The I/P module is in neutral position. The control operation is inactive. See the chapter titled "Configuration" for a detailed description of the individual parameter groups and parameters.

Displays and operating elements

Positioners can be operated locally by means of four push buttons and a liquid crystal display.

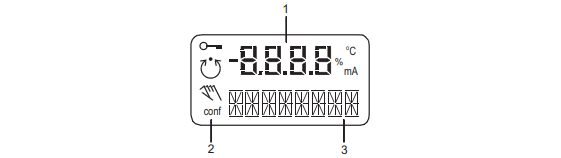

Liquid crystal display

The liquid crystal display, with 160 segments, has been specially designed for the positioner.

Important

The display has been designed for a temperature range of -25 °C ... 80 °C. At temperatures outside this range the display is too sluggish and will be switched off.

Value display with unit

This 7-segment display with four digits indicates parameter values or parameter reference numbers. For values, the physical unit (°C, %, mA) is also displayed.

Designator display

This 14-segment display with eight digits indicates the designators of the parameters with their status, of the parameter groups, and of the operating modes

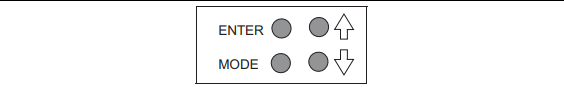

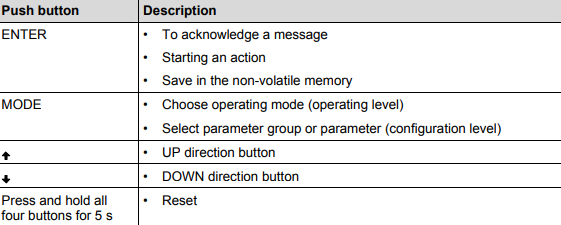

Push buttons

The four push buttons ENTER, MODE, ↑ and ↓ are pressed individually or in certain combinations according to the function desired.

Basic functions

Functions on the operating level Changing the mode (operating level)

1. Press and hold MODE. The reference number (top) and the designator (bottom) of the active mode are displayed.

2. Additionally, press or until the reference number and the designator of the desired mode are shown on the display.

3. Release the buttons

Important The desired mode is only activated and saved in the non-volatile memory once the MODE button is released.

Adjusting the contrast (operating level)

1. Press and hold the ENTER button. After approx. 1.5 seconds the display switches to the contrast value.

2. Additionally, press or to change the contrast. The value selected is active immediately so that you can check the contrast in the display.

3. Release the buttons. Once the ENTER button is released, the value is saved in the nonvolatile memory.

Switching to the configuration level

1. Simultaneously press and hold the or buttons. 2. Press ENTER once and release it again. Press and hold ↑ and ↓ until the countdown from 3 to 0 is complete (duration: approx. 3 seconds).

Important If you release the direction buttons before the countdown is complete, the configuration level will not be activated.

3. Release the or buttons. The configuration level appears. The first parameter (ACTUATOR) of group 1 (STANDARD) is displayed. The configuration symbol is also shown on the display.

Functions on the configuration level Switching to another parameter group

1. Simultaneously press and hold the MODE and ENTER buttons. The display indicates the reference number (top) and the designator (bottom) of the current parameter group of the positioner. 2. Additionally, press or until the reference number and the designator of the desired parameter group are displayed. 3. Release all buttons. The first parameter of the newly selected parameter group is displayed. The desired parameter can be adjusted within the group.

.png)

.png)

.png)