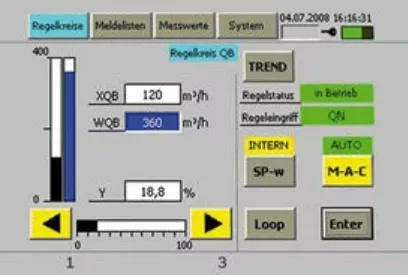

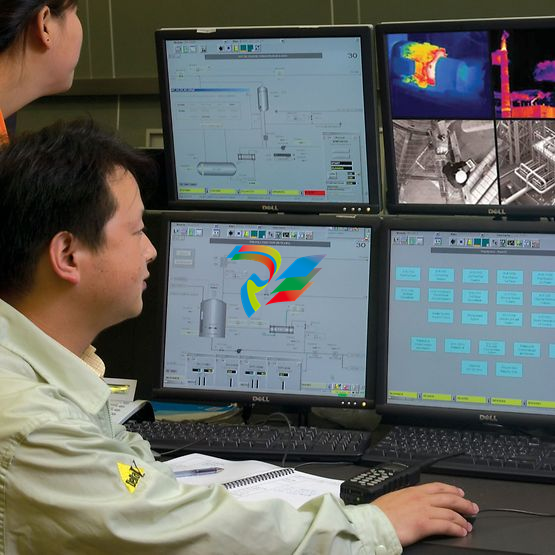

Part Number IS220PRTDH1A Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VIe Function Module Availability In StockIS220PRTDH1A is a Resistance Temperature Device Input Module manufactured and designed by General Electric as part of the Mark VIe Series used in distributed control systems. An RTD input terminal board and one or more I/O Ethernet networks are connected electrically by the Resistance Temperature Device (RTD) Input (PRTD) pack. An acquisition board dedicated to the thermocouple input function is included in the pack, along with a processor board that is shared by all Mark VIe distributed I/O packs. Up to eight RTD inputs can be supported by the I/O pack, while the TRTD terminal boards can support up to sixteen RTD inputs. A DC-37 pin connector that links directly to the terminal board connector for the pack, as well as a three-pin power input, are used for input. There are two RJ45 Ethernet connectors for the output. Indicator LEDs are used to display visual diagnostics. IS220PRTDH1A Compatibility The RTD input terminal boards TRTDH1D, H2D, and SRTD board are all compatible with PRTDH1A, but the DIN-rail mounted DRTD board is not. The compatibility information is provided in the table below. One I/O pack and one or two network connections are used in simplex. Two I/O packs with one or two network connections are used by Dual. Three I/O packs with one network connection each are used by TMR. The TRD input circuit is galvanically isolated by the PRTD. This necessitates modifications to the TRTDH1D and TRTDH2D boards' terminal board transient protection. The board's H1D version offers filtering that is compatible with the PRTD standard scan rate. When the rapid scan rate of PRTD is chosen, the H2D version of the terminal board offers less filtering to enable proper performance. Although there won't be any physical harm, if PRTD is mounted on an earlier version of the TRTD board, an incompatibility will be detected. IS220PRTDH1A Installation Securely mount the desired terminal board. Directly connect one or two PRTDs to the connections on the terminal board (for simplex control of eight or 16 RTDs).

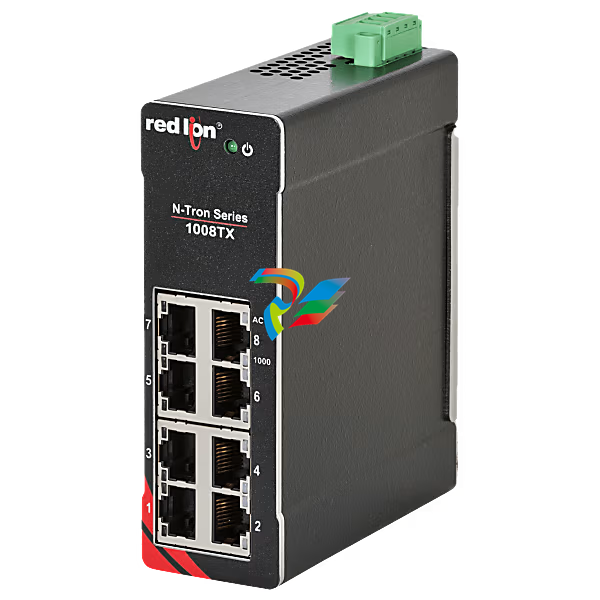

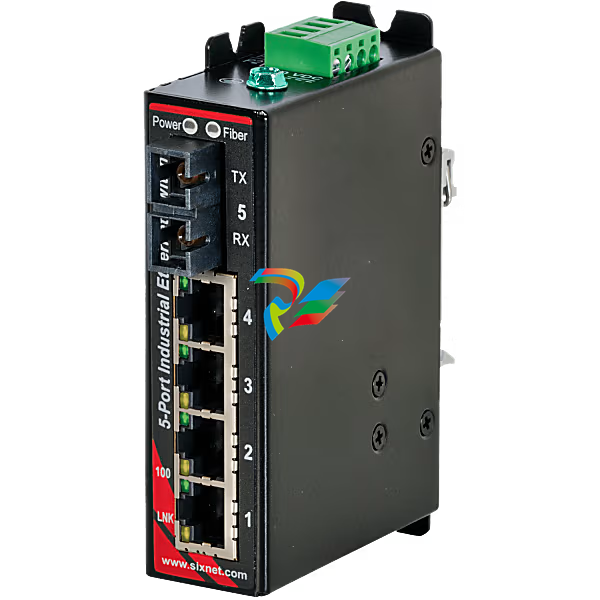

Utilizing the threaded inserts next to the Ethernet ports, mechanically secure the packs. The inserts attach to the terminal board type-specific mounting bracket. It is important to position the bracket such that the DC-37 pin connector between the terminal board and the pack is not subjected to a right angle force. Only one adjustment should be necessary during the lifespan of the product. Depending on the system configuration, connect one or two wires to ensure optimal operation across either port. It is customary to link ENET1 to the network connected to the R controller when dual connections are employed. Connect the connector on the side of the pack to provide electricity to the battery. The I/O pack includes a built-in soft-start feature that limits current inrush when power is applied, so it is not essential to unplug the cable before connecting it. To customize the I/O pack as appropriate, use the ToolboxST* application. Processor Board Operation The I/O pack or module function-specific acquisition board is connected to the processor board. The soft-start circuit ramps up the voltage available on the processor board when input power is applied. The processor reset is turned off and the local power supply is turned on in order. After finishing self-test routines, the processor loads application code from flash memory that is particular to the I/O pack or module type. To verify that the application code, acquisition board, and terminal board are correctly matched, the application code reads the board ID information. When there is a good match, the processor makes an effort to start Ethernet connections by asking for a network address. The dynamic host configuration protocol (DHCP), which is the industry standard, and the terminal board's unique identifier are both used in the address request. Following Ethernet startup, the CPU runs the application, programs the on-board logic, and permits the acquisition board to start working. The whole circuitry required to enable the I/O pack to function from one or two Ethernet inputs is contained in the processor application code. Both network pathways are constantly active when two Ethernet inputs are used. The I/O pack or module operation will not be hampered by a failure of either network, and the functioning network connection will reveal the failure. Compared to a traditional hot-backup system, where the second port is only used when the primary port fails to function, this configuration is more fault tolerant. The processor's Ethernet ports automatically negotiate between half-duplex and full-duplex operation at speeds between 10 MB/s and 100 MB/s. The processor board is common to all Mark VIe Ethernet I/O packs or modules. It contains the following: A quick processor with RAM and flash memory is number one. Two plugs for entirely independent 10/100 Ethernet ports Hardware reset and watchdog timer circuit A sensor for internal temperature LEDs that indicate the status The capacity to read IDs on other boards and electronic identification An input power connector with a current limiter and a gentle start Local power supplies, which also include monitoring and sequencing IS220PRTDH1A Diagnostics A power-up self-test that examines the hardware on the CPU board, Ethernet ports, RAM, and Flash memory. Constantly checking if the internal power supply is operating properly Verifying that the hardware set matches by comparing the electronic ID data from the CPU, acquisition, and terminal boards, then checking that the application code loaded from flash memory is appropriate for the hardware set. Hardware limit checking for each RTD type is based on predetermined (non-configurable) high and low levels that are placed close to the working range's edges. The input is no longer examined once this limit is reached, and a logic signal is set instead. A composite diagnostic alarm, L3DIAG PRTD, referring to the entire board is generated if the hardware limits for any one of the eight inputs are reached. Information about each diagnosis is available from the toolbox. Individual diagnostic signals may be latched, and the RESET DIA signal may be used to reset them. System limit testing for each RTD input is done using customizable high and low levels. These restrictions, which can be adjusted for enable/disablement and latching/non-latching, can be utilized to trigger alarms. The out-of-limit signals are reset via RESET SYS. The toolbox offers information on each diagnosis in detail. The diagnostic signals can be individually latched and, if they become healthy, reset with the RESET DIA signal.IO PACK, RTD IN/OUT

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|