Yaskawa Σ -V series

Easy and efficient work is no longer a dream. The Σ -V series servo drive can make your dream come true.

Yaskawa Σ -V series

Outstanding mechanical properties are all at your fingertips!

Easy and efficient work is no longer a dream. The Σ -V series servo drive can make your dream come true.

The new no-adjustment function equipped in the Σ -V series breaks the common sense that servo drives cannot operate smoothly without adjustment, achieving immediate use upon connection.

The new advanced automatic tuning function of the Σ -V series not only shortens the installation time but also fully exploits the performance of the machinery.

Features

Excellent performance

It features a relatively high amplifier responsiveness in the same industry, significantly reducing the setting time

It is only 1/12 of our company's previous products

The vibration suppression function has been enhanced

By adding and improving the vibration suppression function, the following performance can be enhanced and the setting time shortened.

In addition, it can also reduce the vibration (noise) during driving and the vibration at the mechanical front end when stopping.

When combined with medium-inertia servo motors, it enhances mechanical performance

Easy to start

Shorten the installation time

According to the wizard prompts, simple parameter Settings can be made

The wiring check can be completed in one go through the SigmaWin+ wiring confirmation function.

Real-time tracking and adjustment status can be achieved, and confirmation can be completed instantly.

In addition to being easy to start, it is also equipped with various user-friendly functions!

Servo motor capacity selection software SigmaJunmaSize+

Select the appropriate type based on the application: taking into account the moment of inertia, DB resistance, etc

Tuning is simple

New type of no-adjustment function

Even without servo adjustment, it can be driven without vibration when the load moment of inertia changes by no more than 20 times.

Setting time: 100 to 150ms range

New advanced automatic tuning function

Based on the command filter function and feedback gain adjustment function, an automatic feedforward gain adjustment function has been added, allowing for appropriate adjustments. Through the friction compensation function, the irregularity of friction during driving can be automatically leveled.

Setting time: 10ms level

New single-parameter tuning function

It can be finely adjusted to further enhance mechanical performance.

Setting time: 0 to 4ms range

Shorten the time for fault diagnosis during maintenance

SigmaWin+ Engineering Tools (PC Software)

Alarm diagnosis function: Infer the cause of the alarm and promptly prompt the handling method.

Excellent scalability

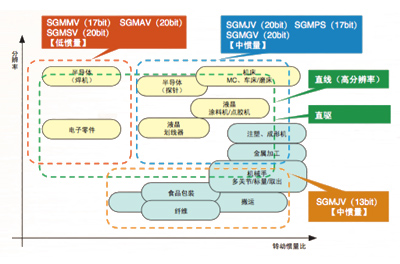

The types of servo motors that match the machine are complete

Medium inertia servo motors → help improve the stability of machinery

Small-inertia servo motors → can achieve high-speed acceleration and deceleration

All kinds of servo actuators

Supports all DD motors, linear motors and linear sliders

It is standardly equipped with five instruction forms

· Analog voltage, pulse sequence command type

· Equipped with INDEXER functionality type

· MECHATROLINK-II communication command type

· Equipped with DeviceNet communication function type

·MECHATROLINK-Ⅲ Communication command type

It is equipped with various communication interfaces and optional modules for various feedback

It is equipped with various communication interfaces and optional modules for various feedback

The standard products comply with safety standards

The main body of the servo unit complies with the STO function stipulated in the international standard IEC61800-5-2. [Newly developed by the company (March 2007)] when used in combination with the security module, it complies with the STO function, SS1 function, SS2 function and SLS function stipulated in the international standard IEC61800-5-2. [Company New Development (May 21, 2010)]

The equipment complies with the functions of SEMI "F47" standard (when using three-phase AC200V)

It is easily applicable to semiconductor and liquid crystal manufacturing equipment

We offer a wide range of motor products to meet the diverse market demands and various applications

.png)

.png)

.png)